FRAME

DOOR

N

NB

B

T

To

o e

en

nssu

urre

e cco

orrrre

ecctt o

op

pe

erra

attiio

on

n o

off

ccllo

osse

err tth

he

erre

e m

mu

usstt b

be

e a

a 3

3m

mm

m//

1

1

//

8

8

”

” g

ga

ap

p

b

be

ettw

we

ee

en

n tth

he

e ttw

wo

o ffiix

xiin

ng

g p

plla

atte

ess w

wh

he

en

n

tth

he

e d

do

oo

orr iiss iin

n tth

he

e ccllo

osse

ed

d p

po

ossiittiio

on

n..

T

Th

he

esse

e iin

nssttrru

uccttiio

on

nss a

arre

e b

ba

asse

ed

d o

on

n tth

he

e

g

ga

ap

p b

be

ettw

we

ee

en

n d

do

oo

orr a

an

nd

d ffrra

am

me

e b

be

eiin

ng

g

3

3m

mm

m +

+

-- 1

1..0

0m

mm

m..

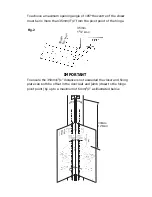

• Drill 4 x 28mm/1

1

/

8

” Ø holes x30mm/1

5

/

16

”

deep to accept frame plate assembly as

indicated on template.

• Drill 2 x 28mm/1

1

/

8

” Ø holes x5mm deep

to accept frame plate ends.

• Remove excess timber between drilled

holes to accommodate frame plate.

FRAME PREPARATION FOR

FRAME PLATE

3

• Drill 4 x 26mm/1

1

/

16

” Ø x

185mm/7

5

/

16

” deep holes to accept

closer body as indicated on the

template.

• Drill 2 x 28mm/1

1

/

8

” Ø holes x5mm to

accept door plate ends.

• Remove excess timber between

drilled holes to accept the closer body

and door plate.

4

DOOR PREPARATION FOR

BODY & DOOR PLATE

FRAME

DRILL

TO

30mm/1

/

16

”

DEEP

5