3.

Apply lubricant to all points in this Operation and

Maintenance Manual, “Maintenance Interval

Schedule”.

4.

Drain the crankcase oil. Replace the crankcase oil

and change the oil filters. For the proper

procedure, refer to this Operation and

Maintenance Manual.

5.

Add VCI oil to the crankcase oil. The volume of

VCI oil in the crankcase oil should be 3 to 4

percent.

Note:

If the engine crankcase is full, drain enough

engine oil so the mixture can be added.

6.

Remove the air filter elements. Turn the engine at

cranking speed with the throttle control in FUEL

OFF position. Use a sprayer to add a mixture of 50

percent VCI oil and 50 percent engine oil into the

air inlet or turbocharger inlet.

Note:

The mixture of VCI oil can be added to the inlet

by removing the plug for checking turbocharger boost

pressure. The minimum application rate for the VCI

oil mixture is 5.5 mL per L (3 oz per 1000 cu in) of

engine displacement.

7.

Use a sprayer to apply a mixture of 50 percent VCI

oil and 50 percent crankcase oil into the exhaust

openings. The minimum application rate for the oil

mixture is 5.5 mL per L (3 oz per 1000 cu in) of

engine displacement. Seal the exhaust pipe and

seal any drain holes in the muffler.

8.

Remove the fuel from the secondary fuel filter

housing. Alternately, empty and reinstall the spin-

on fuel filter element in order to remove any dirt

and water. Drain any sleeve metering fuel pump.

Clean the primary fuel filter. Fill with calibration

fluid or kerosene. Install the primary fuel filter and

operate the priming pump. This procedure will

send clean oil to the secondary filter and the

engine.

Open the fuel tank drain valve in order to drain any

water and dirt from the fuel tank. Apply a spray of

calibration fluid or kerosene at the rate of

30 mL per 30 L (1 oz per 7.50 gal US) of fuel tank

capacity in order to prevent rust in the fuel tank.

Add 0.15 mL per L (.02 oz per 1 gal US) of

commercial biocide such as Biobor JF to the fuel.

Apply a small amount of oil to the threads on the

fuel tank filler neck and install the cap. Seal all

openings to the tank in order to prevent

evaporation of the fuel and as a preservative.

9.

Remove the fuel injectors. Apply 30 mL (1 oz) of

the mixture of oils (50 percent VCI oil and 50

percent engine oil) into each cylinder.

Use a bar or a turning tool in order to turn over the

engine slowly. This procedure puts the oil on the

cylinder walls. Install all fuel injectors and tighten

to the correct torque. Refer to Disassembly and

Assembly Manual for more information.

10.

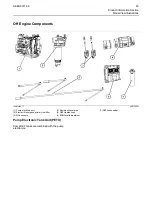

Spray a thin amount of a mixture of 50 percent

VCI oil and 50 percent engine oil onto the following

components: flywheel, ring gear teeth and starter

pinion. Install the covers in order to prevent

evaporation of the vapors from the VCI oil.

11.

Apply a heavy amount of Multipurpose Grease to

all outside parts that move, such as rod threads,

ball joints, linkage.

Note:

Install all covers. Ensure that tape has been

installed over all openings, air inlets, exhaust

openings, the flywheel housing, the crankcase

breathers, the dipstick tubes.

Ensure that all covers are airtight and

weatherproof. Use a waterproof weather resistant

tape such as Kendall No. 231 or an equivalent. Do

not use duct tape. Duct tape will only seal for a

short time.

12.

Under most conditions, removing the batteries is

the best procedure. As an alternative, place the

batteries in storage. As needed, periodically

charge the batteries while the batteries are in

storage.

If the batteries are not removed, wash the tops of

the batteries until the tops are clean. Apply an

electrical charge to the batteries in order to obtain

a specific gravity of 1.225.

Disconnect the battery terminals. Place a plastic

cover over the batteries.

13.

Remove the drive belts from the engine

14.

Place a waterproof cover over the engine. Ensure

that the engine cover is secure. The cover should

be loose enough to allow air to circulate around

the engine in order to prevent damage from

condensation.

15.

Attach a tag with the storage date to the engine.

16.

Remove the waterproof cover at 2 month or 3

month intervals in order to check the engine for

corrosion. If the engine has signs of corrosion,

repeat the protection procedure.

SEBU9071-06

33