Terminology

Certain abbreviations follow the nomenclature of

“SAE J754”. Some classifications follow “SAE J183”

abbreviations, and some classifications follow the

“EMA Recommended Guideline on Diesel Engine

Oil”. In addition to Perkins definitions, there are other

definitions that will be of assistance in purchasing

lubricants. Recommended oil viscosities can be

found in this publication, “Fluid Recommendations/

Engine Oil” topic (Maintenance Section).

Engine Oil

Commercial Oils

NOTICE

For applications above 168 kWCI-4 oil must be used.

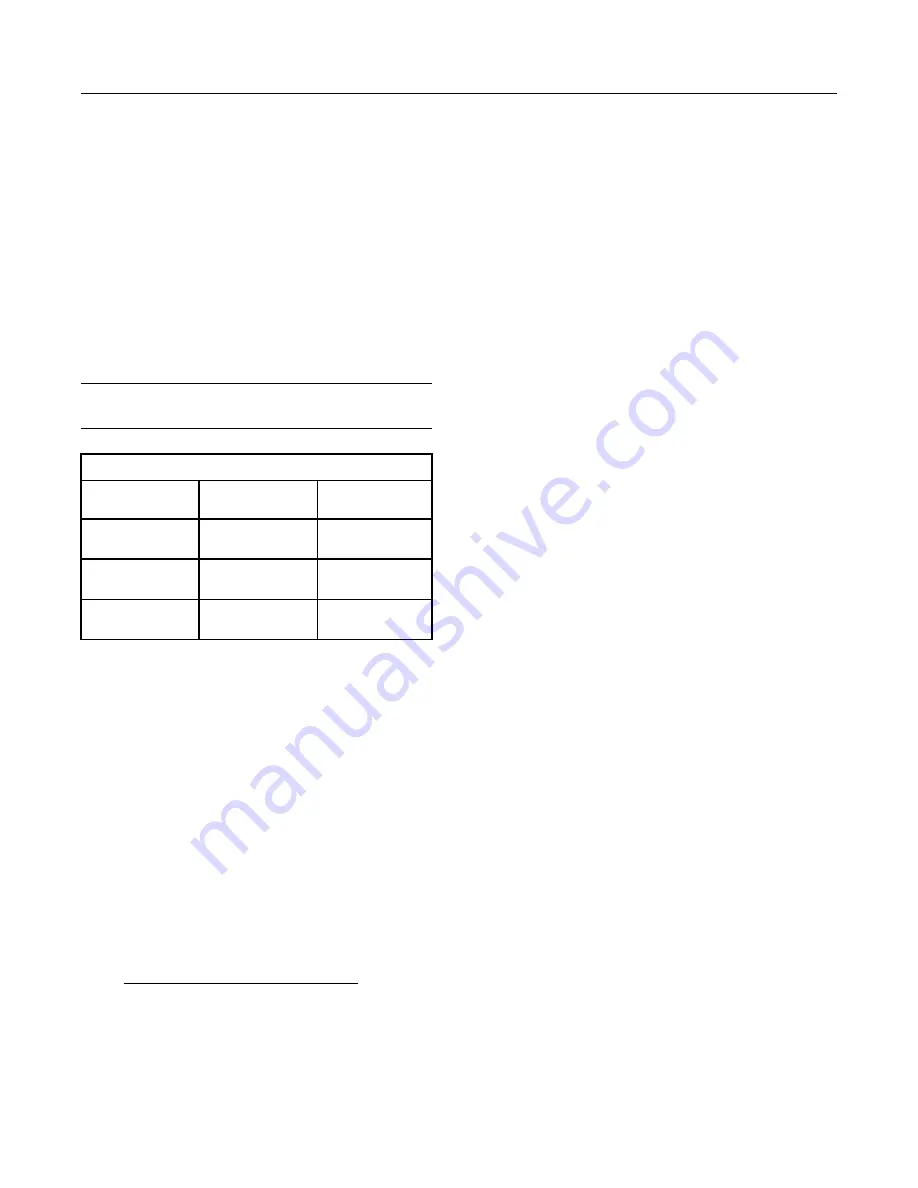

Table 6

API Classifications for the 1106D Industrial Engine

Engine Power

Oil Specification

Maintenance

Interval

Less than 168 kW

(225 hp)

CH-4/CI-4

500 Hours

More than 168 kW

(225 hp)

CI-4

500 Hours

Less than 168 kW

(225 hp)

CG-4

250 Hours

Maintenance intervals for engines that use

biodiesel

– The oil change interval can be adversely

affected by the use of biodiesel. Use oil analysis in

order to monitor the condition of the engine oil. Use

oil analysis also in order to determine the oil change

interval that is optimum.

Note: These engine oils are not approved by

perkins and these engine oils must not be used:

CC, CD, CD-2 and CF-4.

The performance of commercial diesel engine oils is

based on API classifications. These API

classifications are developed in order to provide

commercial lubricants for a broad range of diesel

engines that operate at various conditions.

Only use commercial oils that meet the following

classifications:

• API

CH-4 CI-4

In order to make the correct choice of a commercial

oil, refer to the following explanations:

EMA DHD-1

– The EMA has developed lubricant

recommendations as an alternative to the API oil

classification system. DHD-1 is a Recommended

Guideline that defines a level of oil performance for

these types of diesel engines: high speed, four stroke

cycle, heavy-duty and light duty. DHD-1 oils may be

used in Perkins engines when the following oils are

recommended: API CH-4 and API CG-4. DHD-1 oils

are intended to provide superior performance in

comparison to API CG-4.

DHD-1 oils will meet the needs of high performance

Perkins diesel engines that are operating in many

applications. The tests and the test limits that are

used to define DHD-1 are similar to the new API CH-

4 classification. Therefore, these oils will also meet

the requirements for diesel engines that require low

emissions. DHD-1 oils are designed to control the

harmful effects of soot with improved wear resistance

and improved resistance to plugging of the oil filter.

These oils will also provide superior piston deposit

control for engines with either two-piece steel pistons

or aluminum pistons.

All DHD-1 oils must complete a full test program with

the base stock and with the viscosity grade of the

finished commercial oil. The use of “API Base Oil

Interchange Guidelines” are not appropriate for DHD-

1 oils. This feature reduces the variation in

performance that can occur when base stocks are

changed in commercial oil formulations.

DHD-1 oils are recommended for use in extended oil

change interval programs that optimize the life of the

oil. These oil change interval programs are based on

oil analysis. DHD-1 oils are recommended for

conditions that demand a premium oil. Your Perkins

distributor has the specific guidelines for optimizing

oil change intervals.

API CH-4

– API CH-4 oils were developed in order to

meet the requirements of the new high performance

diesel engines. Also, the oil was designed to meet

the requirements of the low emissions diesel

engines. API CH-4 oils are also acceptable for use in

older diesel engines and in diesel engines that use

high sulfur diesel fuel. API CH-4 oils may be used in

Perkins engines that use API CG-4 and API CF-4

oils. API CH-4 oils will generally exceed the

performance of API CG-4 oils in the following criteria:

deposits on pistons, control of oil consumption, wear

of piston rings, valve train wear, viscosity control and

corrosion.

Three new engine tests were developed for the API

CH-4 oil. The first test specifically evaluates deposits

on pistons for engines with the two-piece steel piston.

This test (piston deposit) also measures the control

of oil consumption. A second test is conducted with

moderate oil soot. The second test measures the

following criteria: wear of piston rings, wear of

cylinder liners and resistance to corrosion. A third

new test measures the following characteristics with

high levels of soot in the oil: wear of the valve train,

resistance of the oil in plugging the oil filter and

control of sludge.

52

SEBU8119-04