12

REMOVING FASTENERS

– cont’d

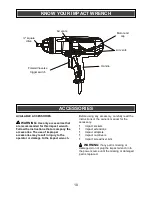

4.

Place impact socket (3) onto the wheel nut.

NOTE:

Make sure the socket is fully

engaged with the nut to avoid potentially

damaging the socket or the wheel nut.

5.

While holding the tool level with the ground

and with a firm grasp, squeeze the

upper

portion

of the trigger switch (4).

When removing fasteners, do not operate the

impact wrench for more than 15 seconds unless

the fastener begins to turn. If the fastener fails to

turn within 15 seconds, reverse the direction of

rotation and operate the impact wrench in a

forward direction on the fastener for a few

seconds. Now switch back to reverse direction

and remove the fastener. This procedure will

usually break loose seized or “frozen” fasteners.

WARNING:

Operating the impact wrench

for more that 15 seconds at a time on a seized

or “frozen” fastener will place severe stress on

the impact wrench and cause damage. It may

also break the fastener.

NOTE:

Once the wheel nut has been removed,

release the trigger switch. The tool will turn

OFF.

TIGHTENING WHEEL NUTS

This impact wrench can be used to tighten

wheel nuts and other fasteners.

1.

Install the correct size of impact socket on

the impact wrench (Fig. 1).

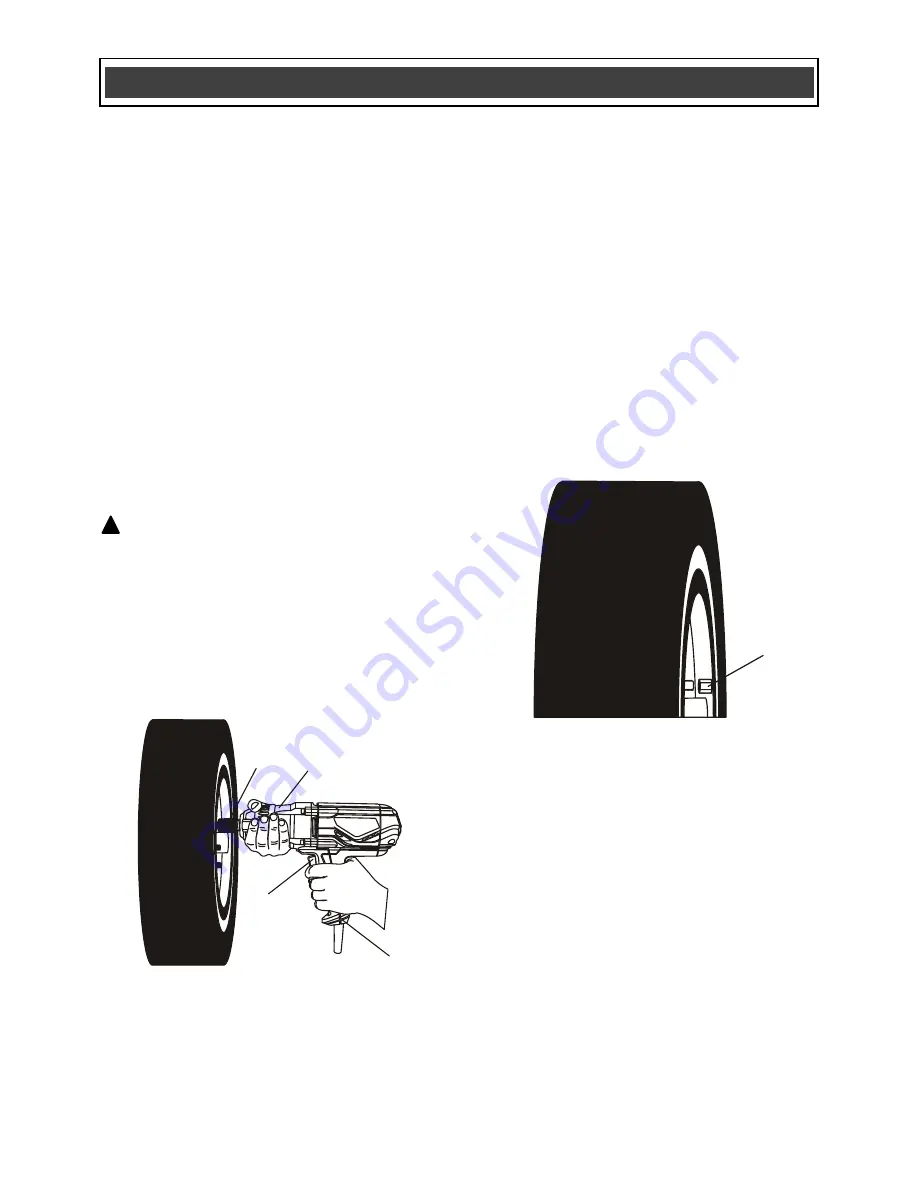

2.

Place the wheel on the wheel studs and

thread one wheel nut (1) clockwise onto

each wheel stud

(Fig. 3).

NOTE:

Thread each wheel nut at least

three full turns onto the wheel stud by hand

to make sure the nuts are NOT cross

threaded. The wheel stud and wheel nut

will be damaged if the nut is cross

threaded.

3.

Grasp the impact wrench handle with one

hand and the front housing of the impact

wrench with the other hand.

4.

Place the impact socket onto the lower

wheel nut (1) (Fig. 4 & 5).

NOTE:

Make sure the socket is fully

engaged with the nut to avoid potentially

damaging the socket or the wheel nut.

5.

While holding the tool level with the ground

and with a firm grasp, squeeze the

lower

portion

of the trigger switch. The impact

wrench will tighten the wheel nut.

!

Fig. 3

1

Fig. 2

1

2

3

4

ASSEMBLY AND OPERATION