11

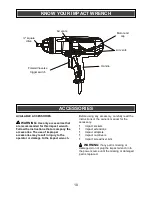

INSTALLING IMPACT SOCKETS

WARNING:

Use only impact sockets

and accessories that are designed for use

with an impact wrench.

Do not use chrome

plated sockets and accessories. Chrome plated

sockets and accessories are designed for hand

use only and MUST NOT be used with an

impact wrench. They may shatter and possibly

cause serious injury.

WARNING:

Always remove the plug from

the power source before changing any sockets

or accessories. You may injure your hand if the

tool is started accidentally.

To install a socket, press the square portion of

the socket (1) onto the square drive (2) of the

impact wrench (Fig. 1).

NOTE:

Slide the socket fully onto the square

drive so the socket is held firmly in place.

FORWARD/REVERSE TRIGGER SWITCH

This impact wrench is equipped with a rocker

style forward/reverse switch (1) (Fig. 2).

1.

To operate the impact wrench in the

forward direction, press and hold the

bottom part of the switch (2). The socket

will rotate in a clockwise direction to

tighten

the fastener.

2.

To operate the impact wrench in the

reverse direction, press and hold the top

part of the switch (3). The socket will rotate

in a counter clockwise direction to loosen

the fastener.

REMOVING FASTENERS

One of the most common uses for the impact

wrench is to remove car wheel nuts for rotating

the tires. Car wheel nut removal is used for

illustrative purposes.

DANGER:

Before attempting to remove

a car wheel, make sure all jacking, wheel

blocking and wheel removal safety

procedures illustrated in the Owner’s Manual

for your car are followed exactly. Failure to

follow those safety instructions could result

in serious injury or death.

1.

Install the correct size of impact socket on

the impact wrench as outlined in Fig. 1

2.

Plug the impact wrench power cord into an

appropriate power source.

3.

Grasp the impact wrench handle (1) with

one hand and the front housing of the

impact wrench (2) with the other hand

(Fig. 2).

ASSEMBLY AND OPERATION

!

!

!

!

WARNING

For safety reasons, the operator must

read the sections of this Owner’s Manual

entitled “GENERAL SAFETY

WARNINGS

”, “POWER TOOL SAFETY”,

“SPECIFIC SAFETY RULES”,

“EXTENSION CORD SAFETY” and

“SYMBOLS” before using this impact

wrench.

Verify the following every time the impact

wrench is used:

1.

Safety glasses and hearing

protection are being worn.

2.

Socket or accessory is “impact

wrench” rated.

3.

Socket or accessory is in good

condition.

Failure to observe these safety rules will

significantly increase the risk of injury.

!

Fig. 1

1

2