Page 12

OPERATION

INTEGRATED RIP AND

CROSSCUT RULER

Marked along the base across the front of

the saw is a ruler for measuring repetitive

cuts. It is marked 5 inches to the right of 0°

in 1/8 inch increments.

DEPTH-OF-CUT ADJUSTMENT

Always keep the correct blade-depth

setting. The correct blade-depth setting for

all cuts should not exceed 1/4 in. below the

material to be cut. Excess blade depth will

increase the chance of kickback and cause

the cut to be rough. One blade tooth below

the material to be cut works is best for

efficient cutting action.

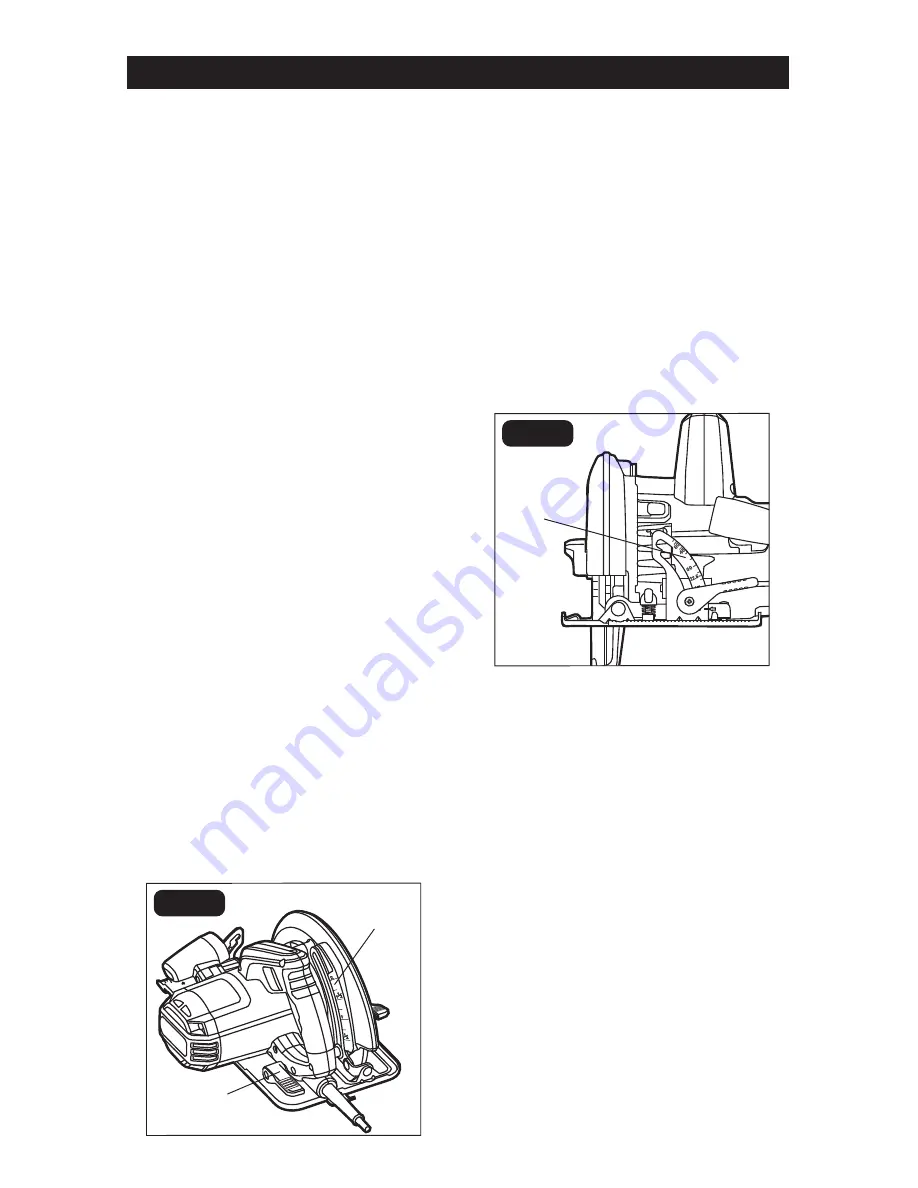

TO ADJUST BLADE DEPTH

(FIG.7)

1. Unplug the circular saw from the power

supply.

2. Loosen the depth-of-cut adjustment

lever by lifting it up.

3. Determine the desired depth of cut.

4. Hold the base of the saw flat against the

edge of the workpiece and then raise or

lower the saw until the indicator on the

bracket aligns with the desired depth on

the depth scale.

5. Tighten depth-of-cut adjustment lever

securely.

FIG. 7

Depth of cut

adjustment lever

Depth scale

BEVEL ADJUSEMENTS

The angle of cut can be adjusted to any

desired setting between 0°and 52°.

Because blade thicknesses vary and

different angles require different settings,

always make a trial cut in scrap material

along a guideline to determine how much

you should offset the guideline on the

workpiece to be cut.

TO ADJUST BEVEL SETTING

(FIG.8)

FIG. 8

45°quick

adjustment

0–45° bevel setting

1. Unplug the circular saw from the power

supply.

2. Loosen the bevel-adjustment knob by

rotating the knob counterclockwise.

3. Tilt the base until the bevel indicator

reaches the desired setting on the

bevel scale.

4. Tighten the bevel-adjustment knob by

rotating the knob clockwise.

45–52° bevel setting

1. Unplug the circular saw from the

power supply.

2. Loosen the bevel-adjustment knob by

rotating the knob counterclockwise.

3. Tilt the base to the 45° quick adjustment

position and push the knob towards the

depth scale. Then you can tilt the base

to the desired setting on the bevel scale

(45–52°).