38

12

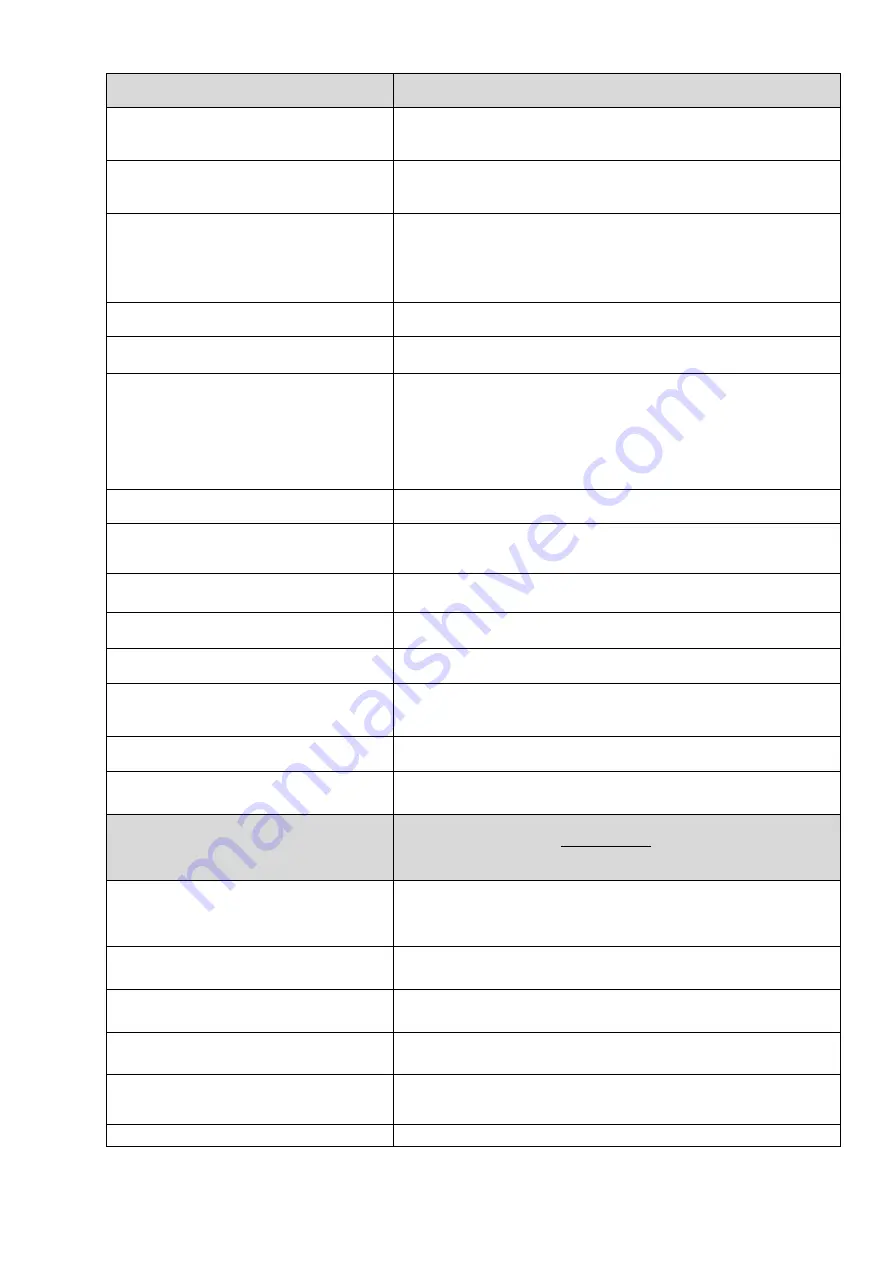

BOILER SERVICE SETTINGS

Burner Settings

Blow in output SUPERV.

Power of the fan in SUPERVISION mode - too high value may

cause boiler overheating or flash back to the feeder; too low

value - may result in fuel pouring.

Feeding Time SUPERVISION

Time of fuel feeding in SUPERVISION mode; Too high value

may cause boiler overheating or fuel pouring; too low - fuel

return to the feeder.

Airflow oper.extend. SUPERV

In SUPERVISION mode of boiler operation, once the fuel dose

has been supplied and the feeder stopped, the fan remains in

operation for a time set in "

Airflow oper.extend.

to fire-up the

fuel dose supplied. Value of this parameter may not be too high

because it may lead to boiler overheating

Fan in SUPERV.

Enable to start and stop the fan in SUPERVISION mode

Min. blow-in output

Min. blow-in output which may be set in the parameters related

with the fan power available in the User's menu.

Cycle order OPERATION

Setting this parameter at "Feeding-

break”

causes the

OPERATION mode will start from a feeding of fuel dose. Setting

this parameter

at ,”Break

-

Feeding” causes the OPERATION

mode will start from break in fuel feeding. This parameter is

helpful in case of frequent boiler change-over from

SUPERVISION to OPERATION mode, where fuel pouring or

furnace lowering may occur.

Fuzzy Logic

Fuzzy Logic settings are available only for boiler manufacturers

Min. preset boiler temperature

This parameter prevents the user to set too low value of boiler

preset temperature. Boiler operation at too low temperature

may cause its quick damage, corrosion, dirt, etc.

Max. preset boiler temperature

This parameter prevents the user to set too high value of boiler

preset temperature.

Reduction value

This parameter determines the temperature at which the boiler

will return from SUPERVISION to OPERATION mode

No fuel detection time

It is the time after which the regulator starts the procedure of

detecting lack of fuel.

No fuel Del T

Difference between preset boiler temperature and actual boiler

temperature, at which the boiler starts the procedure of

detecting lack of fuel.

Maximum feeder temperature

It is the temperature at which the protection against flashback

to fuel feeder activates.

Boiler cooling temp.

Temperature at which boiler cooling down described in sec.

17.2 occurs.

Return Protection4D

A list of settings for boiler return protection function performed

using 4-way valve with electric servo. This function is not active

if return sensor is disconnected or Mix1 support is OFF.

Activation of this function causes all mixers close.

OPERATION mode

This parameter switches ON and OFF the boiler return

protection function performed using mixing valve with electric

servo. Note: do not switch on this function if the valve is not

provided with electric servo!

Min. return temp

Boiler return temperature below the value at which electric

servo closes mixing valve.

Return temp. hyst

Electric servo returns to normal operation at the return

temperature ≥

min.return tempe Return temp. hyst.

Valve closing

It is % opening of mixing valve during active return protection

function. Note: the valve closes with accuracy of +/-1%.

Reserve boiler

The temperature of retort boiler at which reserve boiler (e.g.

gas fired boiler) will be OFF is set using this parameter. Details

- see sec. 11.11

Alarms

Details - see sec. 11.12

Summary of Contents for KSM 17

Page 1: ...Operation and maintenance manual for the KSM series boilers with feeders...

Page 26: ......

Page 31: ...REGULATOR INSTRUCTION MANUAL ecoMAX 910R1...

Page 41: ...USER MANUAL OF CONTROLLER INSTALLATION AND SERVICE SETTINGS ecoMAX 910R1...

Page 47: ...23...

Page 71: ...47...

Page 74: ......

Page 102: ......

Page 103: ......