Commissioning

2

0

1

8

-0

9

17

Reversing the Direction of Rotation of MOT2 (P3)

You can reverse the direction of rotation of MOT2 via parameter bit P3.

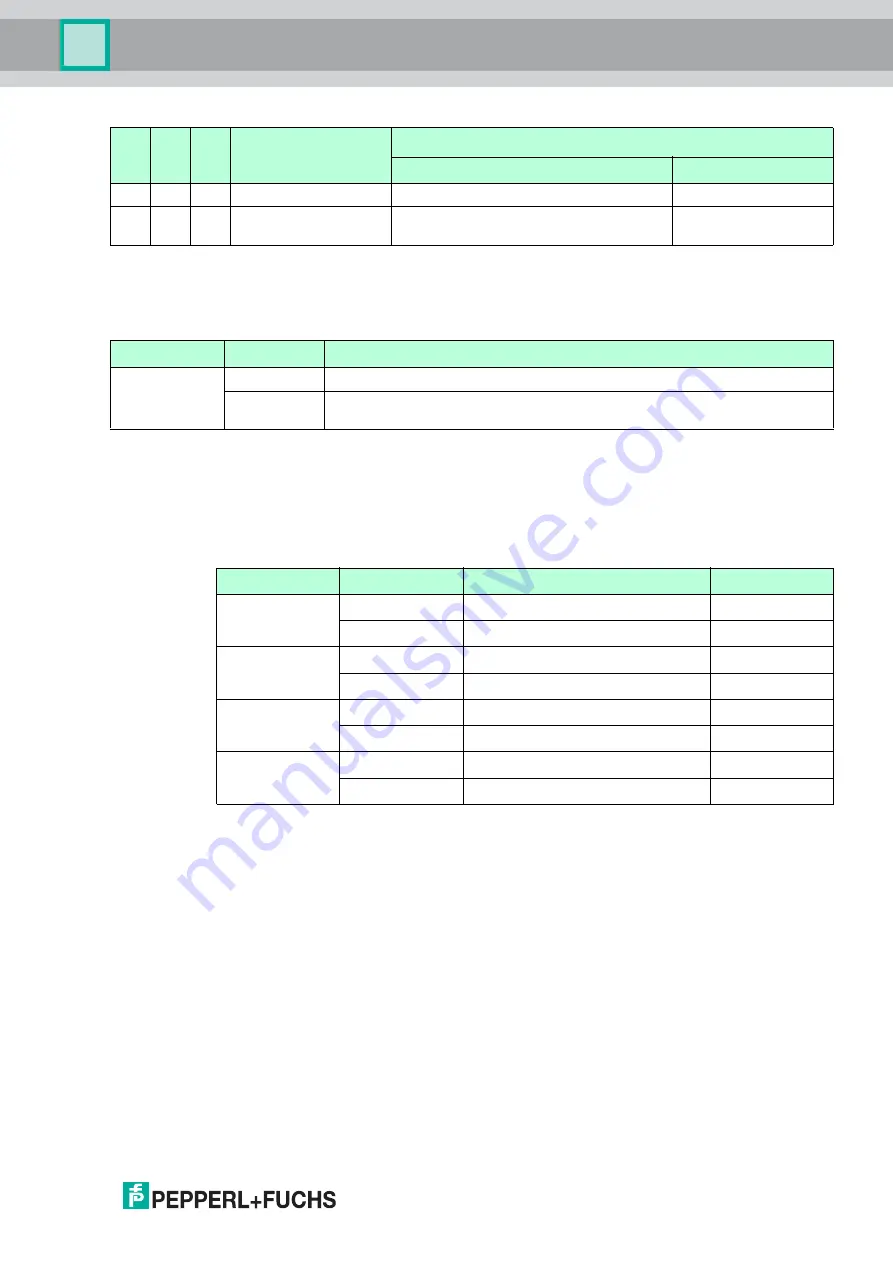

Parameter Bit P3

Status of Sensor Inputs (DI0 ... DI3)

The motor control module transfers the switch states of inputs IN1 to IN4 to the master via data

bits DI0 (IN1) to DI3 (IN4).

There is a filter upstream of the inputs that suppresses pulses

≤

2 ms.

Data Bits DI0 ... DI3

4.2

Configuring the Start/Stop Ramps

Overview

To control the acceleration and to stop the motors, you can set 1 of 8 defined start/stop ramps

for the speed signal SPEED. These ramps always apply to both motors simultaneously. The

ramp duration corresponds to the time from stopped to reaching the maximum speed or from

the maximum speed to stopped. The inclines of the ramps are constant for each of the 8 ramps

and independent of the set speed. The reference value for all ramps is the speed signal

SPEED = 9.7 V. For a lower parameterized speed, the ramp duration is proportionally shorter.

1

1

0

1

8.7 V

3.7 V

1

1

1

1

9.7 V

4.7 V

Default setting

P2

P1

P0

DO0 (MOT1)

or DO1 (MOT2)

Speed signal U

S

Fast (D3=0)

Slow (D3=1)

Parameter bit

State

Function

P3

0

counter-rotating; direction of rotation of MOT2 inverted

1

synchronized, direction of rotation of MOT1 = direction of rotation of MOT2

(Default setting)

Data bit

State

Input switching status

LEDs IN1 ... IN4

DI0

0

Unattenuated, I

IN

≤

0.5 mA

IN1: off

1

Attenuated, I

IN

≥

2.0 mA

IN1: on

DI1

0

Unattenuated, I

IN

≤

0.5 mA

IN2: off

1

Attenuated, I

IN

≥

2.0 mA

IN2: on

DI2

0

Unattenuated, I

IN

≤

0.5 mA

IN3: off

1

Attenuated, I

IN

≥

2.0 mA

IN3: on

DI3

0

Unattenuated, I

IN

≤

0.5 mA

IN4: off

1

Attenuated, I

IN

≥

2.0 mA

IN4: on