MegaTherm Commercial Pool Heating Boiler

Page 13

SECTION 5.

Troubleshooting and Analysis of

Service Problems

1.

For proper service and problem diagnosis of the

boiler and system, the following tools are

required:

a.

Gas pressure test kit with range from zero

to 14" W.C. Either a slack tub manometer

or an accurate gas pressure gauge is

acceptable with proper adaptors which will

connect to the available fittings in the line

and on the gas valve.

b.

Electric meter(s) with the following ranges:

0 to 500 volts A.C.

0 to 1000 ohms continuity.

c.

Millivolt meter with the following ranges:

0 to 50 millivolts. 0 to 500 millivolts.

0 to 1000 millivolts.

d.

Tube cleaning kit consisting of reamer,

stainless steel brush, speed handle and

handle extensions.

e.

Accurate thermometer and pressure gauge.

2.

In addition, the boiler should be equipped with a

thermometer with proper ranges.

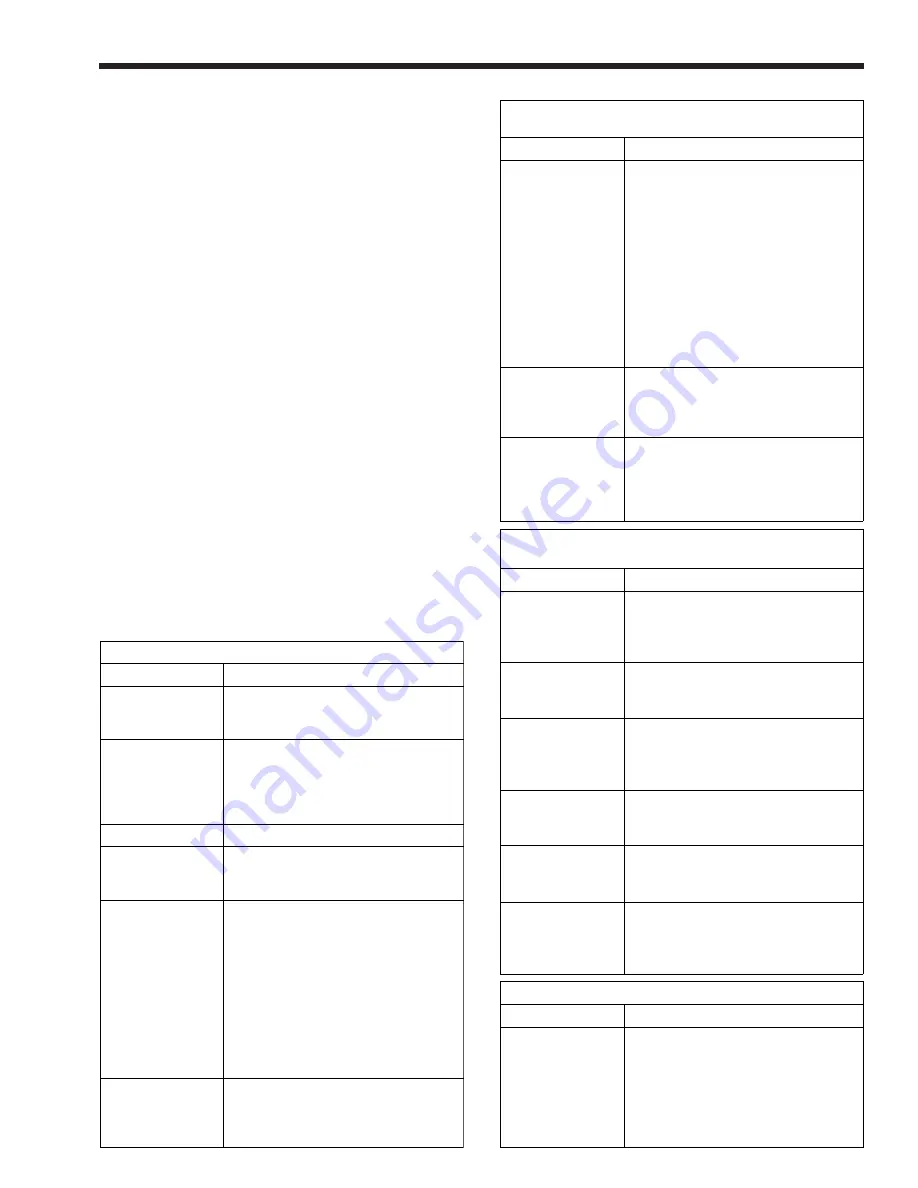

Boiler Will Not Fire

Possible Cause

What To Do

Electric Power

is off.

Check to see that main power switch

is ON. Use testing device to trace

power to boiler junction box.

Operating or

safety control has

opened circuit to

electric gas valve.

Turn off power. Use continuity tester

to check continuity across terminals of

each operating and safety control

switch up to the electric gas valve.

Replace defective control.

Pilot flame is out.

Relight pilot per instructions.

Manual reset

device has

tripped.

Follow instructions for start-up. Reset

pilot safety and all manual reset

safety switches.

No gas pressure to

burners.

Trace gas line to service shutoff cock.

If service cock is open, trace gas line

to meter. If no pressure is present at

meter, call for public utility service. If

gas is present in heater inlet, check

pressures in following sequence:

(1) downstream from pressure

regulator,

(2) downstream from electric gas

valve. Replace or adjust as

necessary.

Electric gas valve

operator is burned

out or shortened.

Disconnect wiring harness at gas

valve terminals. Check continuity to

actuator coil. If open circuit or short is

indicated, replace coil or operator.

Boiler is Pounding, Knocking,

or Emitting Steam from Relief Valves

Possible Cause

What To Do

Lower or no water

flow.

This condition is usually caused by

lack of adequate water flow through

heater. check the following:

1. Is the heater wired into the pump

circuit so that the heater cannot fire

unless the pump is running?

2. Check to see that all valves in

system are open to be sure that water

can circulate through the heater and

the system.

3. Examine pump for clogged

impeller.

4. Check water filter.

Debris from system

is blocking tubes.

Remove header covers. Examine all

tubes and waterways. Use new

gaskets when reassembling. Clean

out tubes.

Scale has formed

in tubes.

This is always caused by heavy

mineral content of the water or

clogged filter. Check the water

chemistry. Replace the filter and

clean all the internal wet surfaces.

Soot in Flueways or in Tubes, or Noxious

Fumes Indicative of Bad Combustion

Possible Cause

What To Do

Combustion air

supply to

equipment room is

inadequate.

Check air supply opening. Look for

debris in screen or louvre which

covers combustion air opening, or for

material blocking the opening.

Stack or vent is

blocked or

restrictive.

Look for blocked stack and excessive

number of elbows in stack or

excessive length of horizontal runs.

Severe down draft

is causing spillage

of flue products

into room.

Check for (1) proper vent cap on

stack; (2) adequate height of stack

above roof; (3) equipment exhausting

air from inside of building.

Gas pressure to

burners is

excessive.

Check gas pressure with

manometer,and adjust with heater

firing at full rate.

Heater not fitted

for the fuel being

supplied.

See nameplate for correct fuel.

Heater installed at

high altitude

without proper

derating.

Installations at altitudes in excess of

2000 ft. above sea level are subject

to jurisdiction of the local inspection

authorities. Check with the factory.

Water Dripping in Firebox

Possible Cause

What To Do

Tube in heat

exchanger has

overheated and

ruptured.

A tube failure is almost always

caused by:

(a) Scale formation in the tube, or:

(b) inadequate water flow through the

boiler.

Replace heat exchanger tube(s) and

check for proper flow.