7

than 500,000 ohms after

drying. A hypot check of 1,500

volts for 230 volt motors and

2,000 volts for 460 volt motors

should be performed.

2. Remove cutters, impeller and

pump parts as described under

“Re plac ing Grinder Parts”.

3. Remove socket head cap screw

(25) in seal plate (17) and

screw two of the screws into

the tapped back-off holes to

force seal plate (17) from seal

housing (27). Pull ing this plate

(17) off will also force seal

(23) from shaft. Re move lower

seal (23) from seal plate (17).

4. Remove snap ring (26) and

pull up per seal (28) from shaft.

It may be necessary to use

packing hooks to remove seal.

Use a screwdriver to break the

upper stationary ce ram ic seal

ring so that it can be removed

easily.

CAUTION: Do not use any old

seal parts. Replace all parts

with new pieces. Mixing old and

new parts will cause immediate

seal failure.

5. When cleaning all parts before

re place ment, check to be sure

sleeve bearing or shaft is not

worn. Be sure all O-rings are in

excellent condition without

cuts or nicks, and replace them

if not i n ex cel lent condition.

Use O-ring lube to prevent

cutting at assembly.

6. After upper seal is replaced we

rec om mend an air test be made

by inserting 5 lb. of air pressure

into the motor hous

ing and

allow am

ple time for air to

escape. If pressure remains

Pump

Maintenance

steady for five minutes

continue by replacing low

er

seal plate, lower shaft seal and

impeller. Repeat the air test in

the seal chamber. If this test

is satisfactory, complete the

assem bly and cutter adjustment

as de

scribed earlier. Next the

pump must be filled with oil.

Start by filling the seal

chamber. Do not fill it

completely. Allow about 1/2"

air space for expansion. Next

fill the motor housing just

above the motor winding.

7. Use only Hydromatic

sub

mers

ible oil in motor

chamber and seal chamber. In

an emergency, a high grade

trans

form

er oil can be used

in the motor chamber and #20

non-detergent automobile oil

can be used in the seal chamber.

Replacing Motor Stator:

1. If necessary to replace stator,

com plete ly dismantle pump as

de scribed above.

2. Drain all oil from upper housing.

Remove drain plug (12) in

bottom of bearing housing, and

remove bearing housing (8)

and rotor and shaft assembly

(33). When hous ing and rotor

are removed, motor leads can

be disconnected through

the bearing cap bore. The

leads are connected with

connectors and must be cut.

DO NOT TAPE LEADS

WHEN REPLACING STATOR

AS OIL WILL DE TE RI O RATE

THE TAPE AND CAUSE

MOTOR FAILURE. USE

ONLY INSULATED BUTT

CONNECTORS.

3. If cord leads are burned, it will

be necessary to replace power

cord and cord group assembly

(1). If any wires in the

connection box (41) are

burned, it will be nec es sary to

replace the connection box

assembly. Connect wires per

con nec tion diagram.

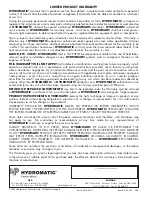

16

25

17

26

64

48

31

46

49

50

51

53

15

18

14

30

29

7

45

32

45

35

8

52

54

24

23

28

13

27

11

10

6

5

3

2

1

47

42

4

34

9

12

59

19

58 57 56 22

21 20 55

41 40 64 38 39

33

43

44

;;;;

;;;

;

;

;;;

;;;

;;;

;

;

;

;

;

40

39

38

8

63

62

53

52

64

65

37

67

50

49

66

51