EQUIPMENT INSTALLATION

CONTINUED

Brine Line Connection

NOTE:

It is recommended that separate brine lines be used

for each tank.

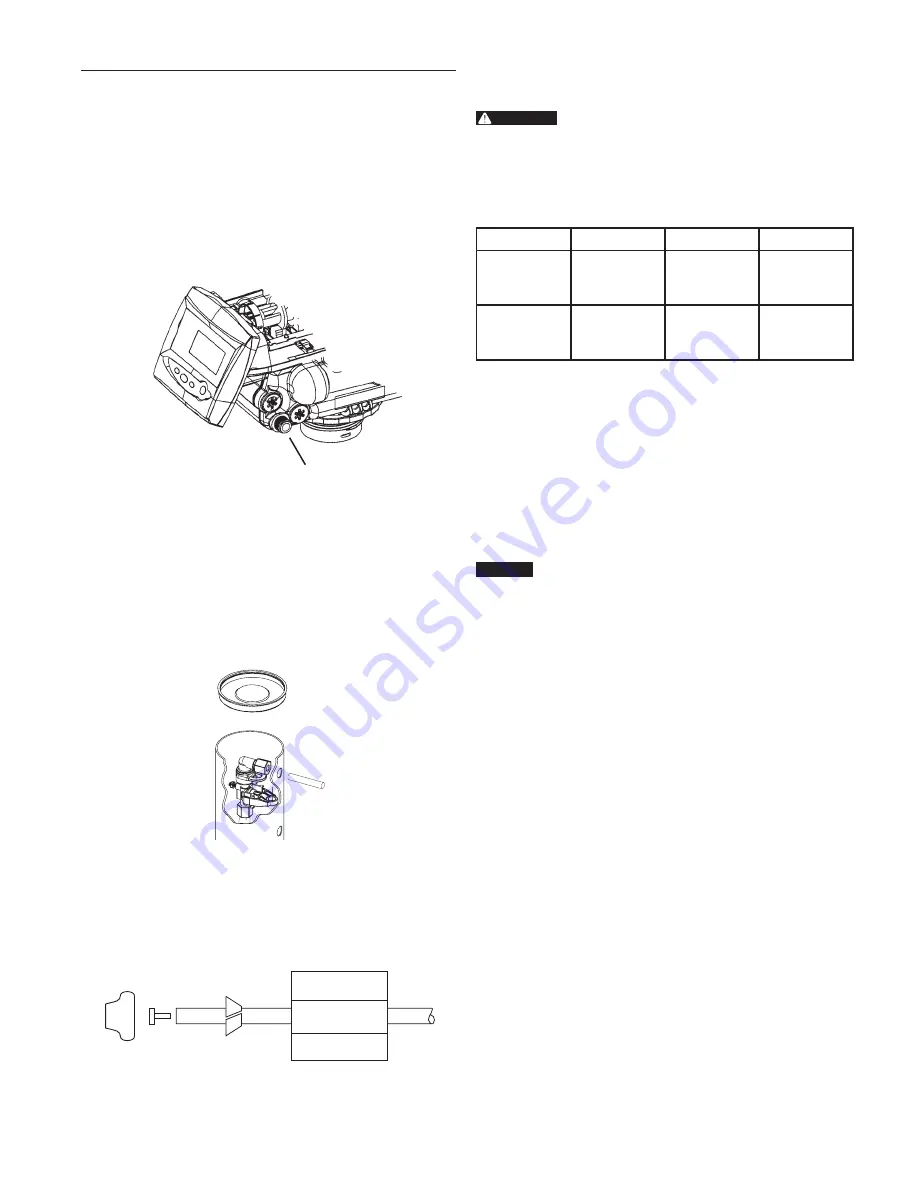

The brine line from the brine tube connects to the valve. Be

certain the connections are hand tightened. Make sure that

the salt line is secure and free from any air leaks. Even a small

leak may cause the brine line to drain out, and the system will

not draw brine from the tank. This may also introduce air into

the valve causing problems with valve operation. Ensure that

plumbers tape is applied to the 3/8" NPT brine line connection

(Figure 6 Regenerant Connection).

Regenerant Line

Connection

Figure 6 Regenerant Connection

To install the brine line:

1. Inside the brine tank, remove the cap from the large

cylinder to gain access to the connection.

2. Be sure the brass insert is in the end of the brine tubing.

Insert the tubing through the opening in the tank.

3. Push the tubing into the plastic nut. Slowly unscrew the nut

until the tubing moves into the connection. The tubing will

hit bottom.

Figure 7

NOTE:

Once the tubing has been pushed into the nut

it cannot be pulled out. The nut will need to be

removed. See Figure 8 for correct assembly.

4. Hand tighten the nut until the connection is tight.

Figure 8

Electrical Connection

WARNING:

This valve and control are for dry location use

only unless used with a Listed Class 2 power

supply suitable for outdoor use.

The 764 Series control operates on a 12 volt alternating

current power supply. This requires use of the supplied AC

adapter. A variety of AC adapters are available from your

supplier for different applications. They include:

AC Adapter

Input Voltage Application

Part Number

Standard

wall-mount

120 V 60 Hz

UL listed

for indoor

installations

1000811

Outdoor

rated

120 V 60 Hz

UL listed

for outdoor

installations

1235448

120 VAC Adapters

Make sure the power source matches the rating printed on the

AC adapter.

NOTE:

The power source should be constant. Be certain

the AC adapter is not on a switched outlet. Power

interruptions longer than eight hours may cause the

controller to lose the time setting. When power is

restored, the time setting must then be re-entered.

NOTE:

Do not connect power by plugging in the transformer

at this time. Doing so may cause difficulty in properly

placing the unit into operation.

CAUTION

Plumbing cannot be used for electrical grounding

when metal inlet and outlet piping is connected to

a non-metal valve.

Connect the inlet and outlet piping together using a

grounding strap or clamp to establish continuity.

AUTOTROL

®

Logix 764 Control Performa Cv Series Valves (273, 278) Service Manual

•

5