© COPYRIGHT 2010 PECO, INC. ALL RIGHTS RESERVED.

P/N 70476 3220-2265 REV 00

5

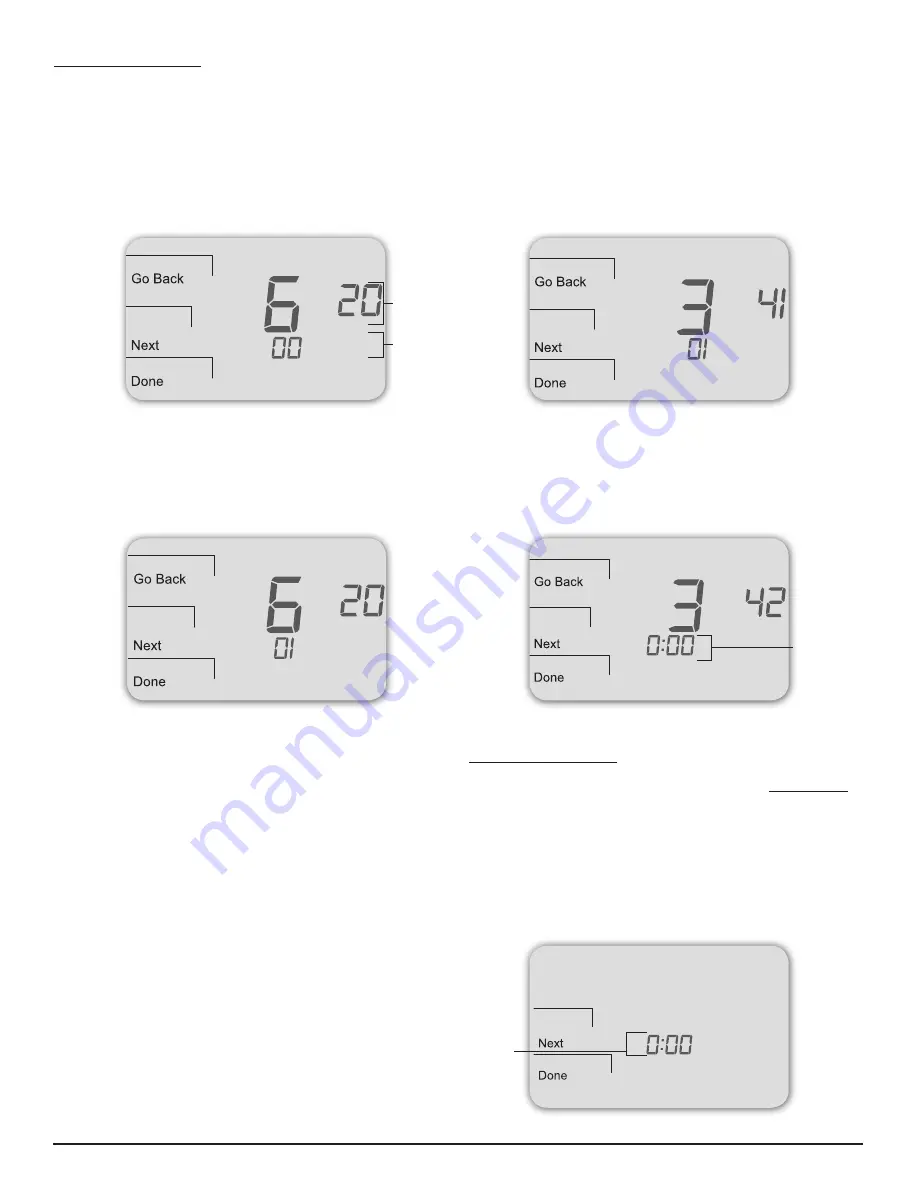

sYstem test Fan: oPtIonal

If continuing from the previous section on this page, skip to Step 2 below. The following

instructions assume that the user enters the Service Menus from the home screen display;

it does not assume that the user has followed in sequence from the previous section.

1. On the thermostat, press the lower left and lower right keys simultaneously for about

fi ve seconds.

Next

,

Go Back

, and

Done

appear (see Fig. 12).

2. Press

Next

until Service Menu 620 appears in the display.

( The default value for Service Menu appears below Service Menu.)

3. In Service Menu 620, press ▲/ ▼to select option “01” to enable fan output

(see Fig. 13).

note:

If 1 is selected, the thermostat will activate the associated output for 10 minutes.

The user should observe that the fan output will turn on.

4. Press

Done

to complete the system test. After verifying the system test, the outputs

are disabled.

optional: the user may also perform system test main output (cool):see table 2,

service menu 600.

User oPeratIon

For detailed instructions on user operation of the T4000 Series, including how to operate

all key functions, please refer to the Performance PRO T4000 Series Operating Manual,

the companion to this installation guide.

Part X: set PIn access For servIce menUs (oPtIonal)

Creating a PIN access code allows the installer to restrict access to Service Menus. First,

PIN access must be enabled in Service Menu 341; second, a three-digit code must be

created in Service Menu 342. After these two Service Menus are properly confi gured, the

thermostat requires the user to enter a PIN access code to enter the Service Menus.

1. On the thermostat, press the lower left and lower right keys simultaneously for about

fi ve seconds.

Next

,

Go Back

, and

Done

appear (see Fig. 14).

2. Press

Next

until Service Menu 341 (Enable/Disable PIN Access) appears in the

display. (Default value “00” appears below Service Menu.)

3. In Service Menu 341, press ▲/ ▼to change digit (fl ashing) value to “01” (see Fig. 14).

note: selecting 01 enables PIn access for the thermostat service menus, and

selecting it is necessary to show service menu 342.

4. Press

Next

.

5. In Service Menu 342, press ▲/ ▼adjust values and create a three-digit PIN access

code. The fl ashing three-digit code appears in the clock area (see Fig. 15).

note: write down the PIn access code, and keep it in a safe place.

6. Press

Done

when fi nished.

verIFY PIn access coDe

Enter the PIN access code upon entering the Service Menus. Note: Flashing digit is active;

it is changed using the ▲/ ▼keys. The active (editable) digit moves

from right to left.

1. On the thermostat, press the lower left and lower right keys simultaneously for about

fi ve seconds.

note

Flashing three-digit code,

Next

, and

Done

appear (see Fig. 16).

2. Press ▲/ ▼to change value of digit furthest to the right, then press

Next

.

3. Press ▲/ ▼to change value of digit in middle, then press

Next

.

4. Press ▲/ ▼to change value of digit furthest to left, then press

Done

.

note

: After step 4 is complete, user is allowed access to Service Menus.

Next

,

Go Back

,

Done,

and Service Menu 100 appear.

Figure 13.

Press Done

to complete

testing and

exit Service

Menus,

or Next to

continue tests.

Figure 14.

Service Menu

341 allows

user to restrict

access to

Service

Menus.

Figure 12.

Service Menu

620 allows

the user to

perform a

System Test

Fan.

Service Menu

Default value

(appears

automatically)

Figure 15.

Service Menu

342 allows

user to create

a PIN access

code.

Flashing

three-digit

code

Figure 16.

PIN access

code fl ashes

when user

enters Service

Menus (after

enabling PIN

access).

Flashing

three-digit

code