6

Installing and Adjusting Abrasive Belts

Our unique belt tensioning system allows you to quickly change out belts in under a minute.

Remove the side knob of the safety cover to expose the belt track.

Loosen the upper spindle handle slightly to allow the spring to put tension on the belt.

Pull main handle towards you. While manually compressing the tension spring, slip the belt off the drive wheel

first, then off the bottom wheel, then off the top crowned wheel.

Install new belt by first pulling the main handle. Start by putting the new belt over the lower wheel and upper

crown wheel, then slip onto the drive wheel. Release the main handle. Snug up the upper spindle handle. DO

NOT OVER TIGHTEN OR YOU WILL DAMAGE THE UNIT.

Adjusting Runout of New or Used Belts

All belts will have to be adjusted at one point or another due to wear or due to their manufacturing process.

DISCONNECT POWER BEFORE CHANGING BELTS.

DeBurr-It! uses another in house innovative design to quickly line belts back up. No tools required and takes

just seconds.

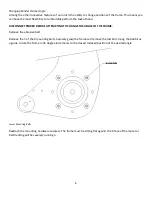

Below is a diagram of the adjustments you will need to use.

Lockscrews should always be finger tight. If they aren’t slightly wiggle the Belt Runout Adjustment back and

forth until you take the tension of the thread of the lockscrews.

Once the adjustment has been made, your belt will track true until it stretches out too much from wear or

until you change the belt.

!!IMPORTANT!! - ALWAYS ADJUST RUNOUT WITH THE SPRINDLE HANDLE TIGHT AND ALWAYS PERFORM

RETENSIONING BEFORE ADJUSTING RUNOUT.

Retensioning – Loosen spindle handle slightly. Retighten spindle handle.

Summary of Contents for DeBurr-It! 248-3

Page 5: ...5 ...