32

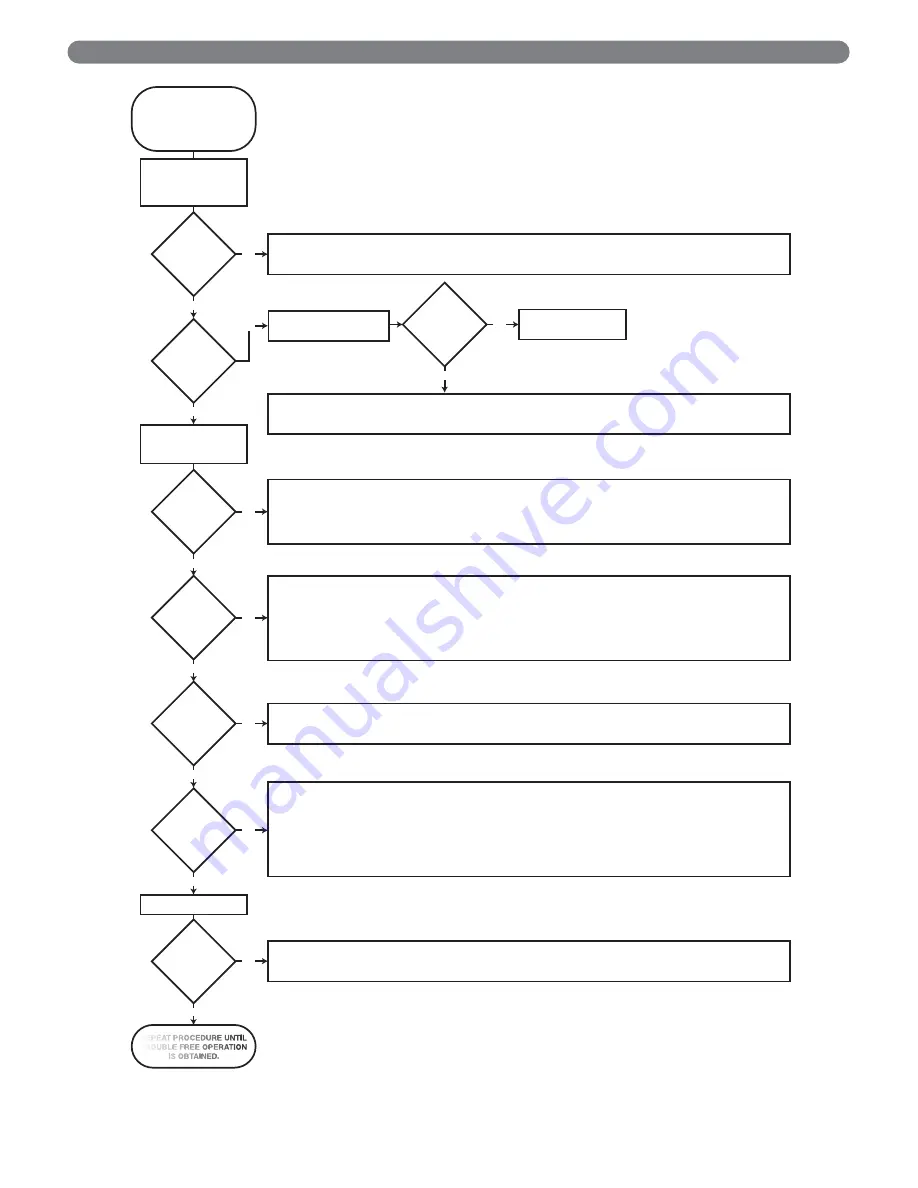

Figure 8.2: Intermittent Ignition System Troubleshooting Sequence

TROUBLESHOOTING

NOTE:

“

CALL FOR HEAT

”

24 VAC

S

UPPLY I

S

CONNECTED TO THE 24 V TERMINAL ON THE CONTROL.

TURN GA

S

S

UPPLY OFF,

TURN THERMO

S

TAT

(CONTROLLER) TO

“

CALL FOR HEAT.

”

POWER TO

MODULE? (24 V

NOMINAL)

S

PARK

ACRO

SS

IGNITER/

S

EN

S

OR

GAP?

PILOT BURNER

LIGHT

S

?

S

PARK

S

TOP

S

WHEN

PILOT I

S

LIT?

S

Y

S

TEM

S

HUT

S

OFF?

S

Y

S

TEM

RUN

S

UNTIL

“

CALL

FOR HEAT

”

END

S

?

MAIN BURNER

LIGHT

S

?

TURN GA

S

S

UPPLY

ON AND RECYCLE

“

CALL FOR HEAT.

”

“

CALL FOR HEAT

”

END

S

CHECK LINE VOLTAGE POWER, LOW VOLTAGE TRAN

S

FORMER, LIMIT CONTROLLER, THERMO

S

TAT (CONTROLLER), AND WIRING AL

S

O.

CHECK AIR PROVING

S

WITCH ON COMBU

S

TION AIR BLOWER

S

Y

S

TEM (IF U

S

ED) AND THAT THE VENT DAMPER END

S

WITCH (IF U

S

ED)

I

S

MADE.

CHECK IGNITION CABLE, GROUND WIRING, CERAMIC IN

S

ULATOR, AND

S

PARK GAP ARE CORRECT.

CHECK BOOT OF THE IGNITION CABLE FOR

S

IGN

S

OF MELTING OR BUCKLING, TAKE PROTECTIVE ACTION TO

S

HIELD CABLE

AND BOOT FROM EXCE

SS

IVE TEMPERATURE

S

.

CHECK THAT ALL MANUAL GA

S

VALVE

S

ARE OPEN,

S

UPPLY TUBING AND PRE

SS

URE

S

ARE GOOD, AND PILOT BURNER

ORIFICE I

S

NOT BLOCKED (PILOT GA

S

FLOWING).

CHECK ELECTRICAL CONNECTION

S

BETWEEN MODULE AND PILOT OPERATOR ON GA

S

CONTROL.

CHECK FOR 24 VAC ACRO

SS

PV-MV/PV TERMINAL

S

ON MODULE. IF VOLTAGE I

S

OKAY, REPLACE GA

S

CONTROL.

IF NOT, REPLACE MODULE.

NOTE: IT MAY BE NECE

SS

ARY TO RECYCLE THE ‘CALL FOR HEAT

”

MORE THAN ONCE TO CLEAR THE PILOT

S

UPPLY TUBE

S

OF AIR.

NOTE: IF CONTROL GOE

S

INTO LOCKOUT OR RETRY DELAY, RE

S

ET THE

“

CALL FOR HEAT.

”

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

CLEAN FLAME ROD.

CHECK ELECTRICAL CONNECTION

S

BETWEEN FLAME ROD AND MODULE.

CHECK FOR CRACKED CERAMIC FLAME ROD IN

S

ULATOR.

CHECK THAT PILOT FLAME COVER

S

FLAME ROD AND I

S

S

TEADY AND BLUE.

ADJU

S

T PILOT FLAME.

IF PROBLEM PER

S

I

S

T

S

REPLACE MODULE.

CHECK FOR 24 VAC ACRO

SS

PV-MV/PV TERMINAL

S

ON MODULE. IF NO VOLTAGE, REPLACE MODULE.

CHECK ELECTRICAL CONNECTION

S

BETWEEN MODULE AND GA

S

CONTROL INCLUDING

S

AFETY CONTROL

S

WIRED IN THE CIRCUIT.

IF OKAY, REPLACE GA

S

CONTROL.

NOTE: IF CONTROL GOE

S

INTO LOCKOUT OR RETRY DELAY, RE

S

ET THE

“

CALL FOR HEAT.

”

CHECK CONTINUITY OF IGNITION CABLE AND GROUND WIRE.

NOTE: IF GROUND I

S

POOR OR ERRATIC,

S

HUTDOWN

S

MAY OCCUR OCCA

S

IONALLY EVEN THOUGH OPERATION I

S

NORMAL

AT THE TIME OF CHECKOUT.

CHECK THAT PILOT FLAME COVER

S

FLAME ROD AND I

S

S

TEADY AND BLUE, PILOT FLAME MU

S

T NOT BE MOVING AROUND DUE TO

OUT

S

IDE AIR FLOW

S

, ETC.

ADJU

S

T PILOT FLAME. CHECK GA

S

PRE

SS

URE MEET

S

APPLIANCE

S

PECIFICATION

S

WHILE APPLIANCE MAIN BURNER ON AND ALL

OTHER GA

S

APPLIANCE

S

ON THE

S

UPPLY ARE OPERATING AT FULL RATE.

IF CHECK

S

ARE OKAY, REPLACE MODULE.

CHECK FOR PROPER THERMO

S

TAT (CONTROLLER) OPERATION.

REMOVE MV LEAD AT MODULE, IF VALVE CLO

S

E

S

, RECHECK TEMPERATURE CONTROLLER AND WIRING. IF NOT, REPLACE

GA

S

CONTROL.

YE

S

YE

S

YE

S

YE

S

YE

S

NO

NO

NO

NO

NO

YE

S

YE

S

NO

PULL IGNITION LEAD AND

CHECK

S

PARK AT MODULE.

S

PARK OK?

NO

REPLACE MODULE

YE

S

S

TART

BEFORE TROUBLE

S

HOOTING,

FAMILIARIZE YOUR

S

ELF WITH

THE

S

TARTUP AND

CHECKOUT PROCEDURE

S

.

REPEAT PROCEDURE UNTIL

TROUBLE FREE OPERATION

I

S

OBTAINED.

NO

Summary of Contents for DE-03

Page 1: ...DE Boilers Series Gas Installation Operation Maintenance Manual ...

Page 26: ...START UP PROCEDURES Figure 7 3 Operating Instructions 24 ...

Page 27: ...25 Figure 7 4 Operating Instructions START UP PROCEDURES ...

Page 32: ...30 TROUBLESHOOTING Figure 8 1 Procedure For Measuring Fan Suction Pressure SEE TABLE 7 ...

Page 39: ...37 This page intentionally left blank ...

Page 42: ...40 REPAIR PARTS Figure 11 2 Base Burners Manifold ...