TOOL INSTALLATION

Your Paslode tool comes ready for immediate use

and can be installed by following these steps:

1. SAFETY - All tool operators and their immediate

supervisors must become familiar with the operator

safety instructions before operating the tool. The

instructions are on page 2 of this manual.

2. Included wuth each tool are one copy of this

Safety and Maintenance manual and one copy of

the Tool Schematic. Keep these publications for

future reference. An ownership registration card is

also included. This card must be completed and

returned to Paslode immediately to register your

ownership.

3. The plastic cap in the air inlet of the tool must be

removed before the male fitting is installed. The fit-

ting must be a male pneumatic type that discharges

the air from the tool when the air line is discon-

nected.

4. Install a filter/regulator/lubricator unit, with a

gauge as close as practical to the tool, preferably

within ten feet. Refer to the Air Systems section of

this manual for air hose requirements and lengths.

In general, no other special installation is required.

5. If the operator is working at a bench or table,

it is usually best to run the air line underneath the

bench. A small tray under the benchtop can hold

the fastener supply and the tool when not in use.

6. If this tool does not work when it is first connect-

ed, do not try to make repairs. Call your Paslode

representative immediately.

TOOL OPERATION

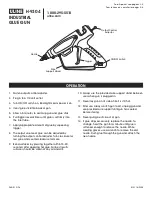

Depth of Drive Adjustment

(On tools equipped with this feature)

The depth of drive adjustment is made by

adjusting the work contacting element. The

lock nut is loosened to allow the element to be

moved up or down. You will need a 3/8 inch

open end or 5/32 inch hex socket wrench to

make this adjustment.

If the tool is overdriving (the fastener head or

crown is driven below the work surface), the

work contacting element should be moved

downward. If the fasteners stand up (the head

or crown is not flush with the surface), the work

contacting element should be moved up.

Adjust the work contacting element until the

fastener head or crown depth meets job re-

quirements.

LOCK

NUT

WORK

CONTACTING

ELEMENT

MOVE UP

TO INCREASE

DRIVE DEPTH

MOVE DOWN

TO INCREASE

DRIVE DEPTH

➔

➔

5

Summary of Contents for T250A-F16

Page 1: ...P Operating and Maintenance Manual PNEUMATIC TOOLS 403606 18 08 07 ...

Page 18: ...P HERRAMIENTAS NEUMATICAS Manual de Operacion y Mantenimiento ...

Page 22: ...SISTEMAS NEUMATICOS 3 ...

Page 23: ...SISTEMAS NEUMATICOS continuación 4 403720 ...

Page 24: ...INSTALACION DE LA HERRAMIENTA 5 FUNCIONAMIENTO DE LA HERRAMIENTA ...

Page 29: ...MANTENIMIENTO 403720 ...

Page 30: ...11 403720 ...