www.parweld.co.uk

9

Type

Application

Colour

Ceriated 2%

DC welding of mild

steel, Stainless

steel, Copper

AC welding

of aluminium,

magnesium and

their alloys

Grey

Zirconiated

AC welding

of aluminium,

magnesium and

their alloys

White

Guide for selecting filler wire diameter

Filler wire diameter

Current range

1/16” (1.6 mm)

20 - 90

3/32” (2.4 mm)

65 - 115

1/8” (3.2 mm)

100 - 165

3/16” (4.8 mm)

200 - 350

The filler wire diameter specified is a guide only, other diameter

wires may be used according to the welding application.

Shielding gas selection

Alloy

Shielding gas

Aluminium & alloys

Pure Argon

Carbon steel

Pure Argon

Stainless steel

Pure Argon

Nickel alloy

Pure Argon

Copper

Pure Argon

Titanium

Pure Argon

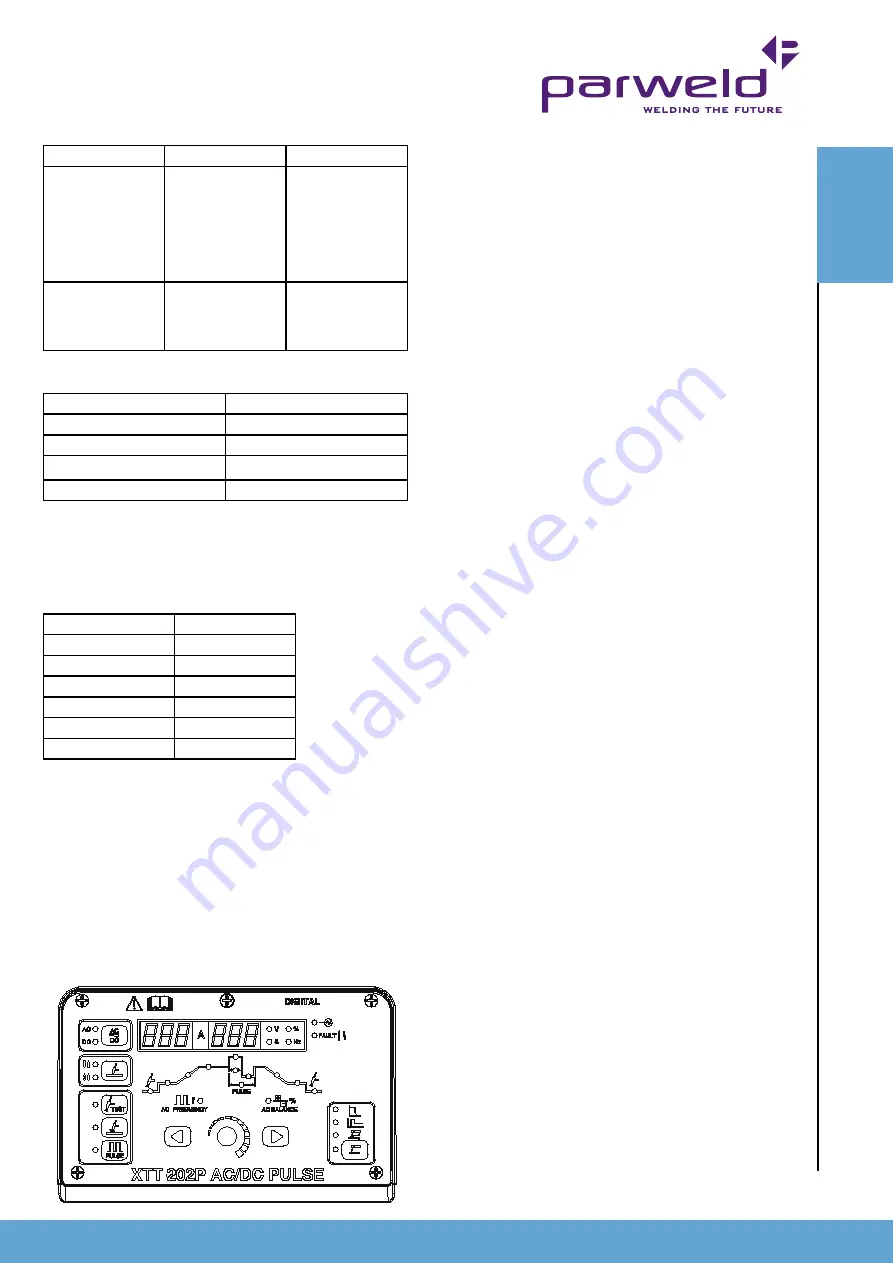

6.3 Machine setup for tIG Welding

6.3.1 DC tIG Welding (no pulse)

note:- shorting or dipping the electrode into the weld pool

for more than 1 second will cause the machine to reduce the

welding power to zero in order to protect the tungsten and

minimise contamination

1) Connect the torch to the - connection and the gas

hose to the gas outlet.

2) Connect the trigger control plug on the torch to the

trigger socket.

3) Connect the Earth lead to the + connection.

4) Set the process mode to 2T or 4T if you prefer a

latching trigger action. (Note in 4T position you must

press and release to start the process and press and

release again to stop the process) (A)

5) Select DC output (B)

6) Select HF start (C)

7) Using the toggle buttons (D) move the illuminated

LED to the gas pre-flow position (E)

8) Adjust the parameter value by rotating the knob (F)

This can be adjusted from 0.1 to 1.0 seconds. The

value is displayed on the Multifunction display (G)

9) Press the toggle button (D) to move the LED to

the initial current (H) This can be adjusted from 5 to

200Amps. The value is displayed on the Multifunction

display (G).

note this function only operates in 4t

switch mode

10) Press the toggle button (D) to move the LED to the

slope up time (I) This can be adjusted from 0 to 10s.

The value is displayed on the Multifunction display (G).

2s is a good initial setting.

11) Press the toggle button (D) to move the LED to the

main welding current (J) This can be adjusted from

5 to 200A. The value is displayed on the amperage

display (O). Refer to the TIG welding guide for a

recommended welding current.

12) Press the toggle button (D) to move the LED to the

slope down time (K) This can be adjusted from 0 to

10s. The value is displayed on the Multifunction display

(G). 2s is a good initial setting.

13) Press the toggle button (D) to move the LED to the

final current (L) This can be adjusted from 5 to 200A.

The value is displayed on the Multifunction display (G).

note this function only operates in 4t switch mode

14) Press the toggle button (D) to move the LED to the

Post Gas time (M) This can be adjusted from 0.1 to

10s. The value is displayed on the Multifunction display

(G). 3s is a good initial setting.

You are now ready to weld. The above settings are

a guide and you should adjust to suit the job you are

welding if you are unfamiliar with the machine try to

adjust only one parameter at a time so you become

familiar with its effect.

H

A

B

C

F

D

E

G

D

I

J

K

L

M

O

O

pera

t

IO

n

O

pera

t

IO

n