Rodless, magnetically coupled pneumatic cylinders

6

4.2 Installation

4.2.1 Mechanical

•

Make sure the payload is

only

fastened to the provided fixing points.

•

Position the payload in such a way that the forces and tilting moments on

the piston are below the limits specified in the

P1Z catalog.

•

Use appropriate coupling and connecting procedures to prevent any

constraining forces from external linear loads.

•

Observe the permissible weight and speed as specified in the damping

diagram in the

P1Z catalog

. Compliance with these specifications is

mandatory.

4.2.2 Pneumatic

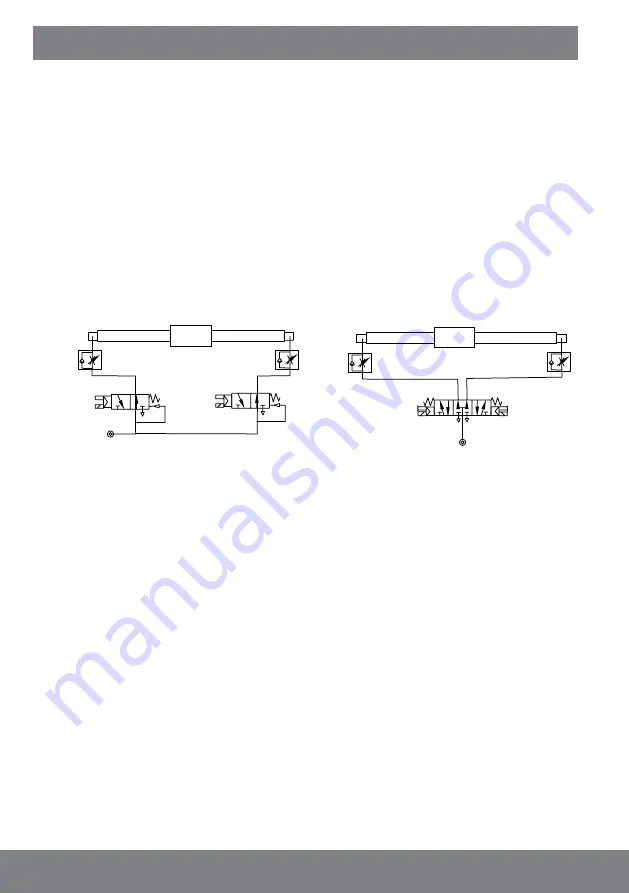

Switching examples

•

Use two 3/2 or one 5/3 directional control valve to control the cylinder. The

normal setting is open.

•

Avoid any uncontrolled movements when commissioning or unintentionally

stopping the machine.

•

Use filling units, soft-start valves, etc., from the range offered in our catalog.

•

Use the control mechanism to ensure that the piston cannot move against

a completely vented cylinder barrel.

•

Use throttle check valves from the range in our catalog to set the speed.

These valves are bolted directly into the cylinder.

•

Make sure the compressed air ports are sufficiently large.

•

Do not position magnetic switches close to ferritic parts or moving loads.

4.3 Lubrication

The P1Z is suitable for operation with

oil-free

compressed air.

Once they have been operated with oiled compressed air, the cylinders must

continue to be operated with oiled compressed air.

(Basic model and model with parallel rod guidance)