5

www.parker.com/euro_pneumatic

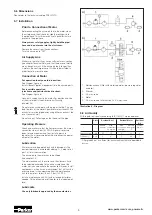

5.6 Dimensions

5.7 Installation

Prior to Connection of Motor

Before connecting the air supply line to the motor, clean

the air pipe and the air hose by slightly blowing air into

the pipe/hose. This will remove any dirt particles that are

present in the pipe/hose.

Always wear safety goggles, tightly hold the pipe/

hose and do not move into the air stream.

Remove the covers from the connections.

Turn the air-supply to “OFF”.

Air Supply Line

Make sure, that all air lines have a sufficient cross-section

(see chapter Technical Data) and that there are no throttle

areas, bends or kinks. If the air supply line is longer than

2 meters, the next larger hose I.D. should be installed in

order to avoid a loss of power.

Connection of Motor

For operation in only one turn-direction:

See Diagram, figure a)

Install silencers (optional equipment) into the unused ports.

For reversible operation

(clockwise and anticlockwise direction):

See Diagram, figure b)

Connect 2 supply lines to the motor. For position and size

of the air inlet ports, see Dimensional Drawing

(chapter 5.6).

Do not close unused ports with a plug or the like. This may

lead to a loss of the motor’s power or motor standstill. The

exhaust air may be piped away using either an exhaust line

or a silencer as well.

Do not use any Teflon tape on the threads of the pipe.

Operating Pressure

Check and make sure that the flow-pressure at the motor

connection side is 6 bar (85 PSI). A higher air pressure

leads to increased wear and tear (install a pressure

regulator). An air pressure below 6 bar reduces the power

output of the motor.

Lubrication

All motors may be operated only with lubricated air. The

best performance is achieved by adding 1 – 2 drops of oil

per 1 m³ of air consumption.

The air supply to the motor has to be filtered

(see chapter 5.8).

The maintenance unit, the valves and the silencers have

to be selected according to the air consumption of the

motor, not in accordance to the connection threads. Install

components, which have a measurement that will limit the

pressure drop – when measured from the maintenance

unit to the motor – to less than 0.5 bar (7.25 PSI).

Install a maintenance unit, fill it with oil and adjust oiler as

needed. Fill the oil container of the oiler to the indicated oil

level.

Lubricants

Use only lubricants approved by the manufacturer.

Please refer to the technical catalog PDE2555TC

1. Maintenance unit (filter with water separator, pressure regulator

and oiler)

2. Silencer

3. 2/2-way-valve

4. Motor

5. 5/3-way-valve or alternatively 2 x 3/2-way-valve

Illustration 2 - Diagram

5.8 Air Quality

With regard to air quality according to ISO 8573-1 we recommend:

Class

Residual Dust

Residual Water

Residual

Oil

particle max.

max. pressure content

size um concentrati concentrati dew-point mg/m

3

on mg/m

3

on mg/m

3

°C

Lubricator air

-/4/4

25

10

5

+3

5

Oil-free air

6/3/3

5

5

1

-20

1

* Filter grade 8 µm is sufficient for units machines that are operated in

dry run.

a)

b)