18

DME012-RX - DME080-RX

6.

Troubleshooting guide

In the unlikely event that a problem occurs on the equipment, this troubleshooting guide can be used to identify the probable cause and

remedy.

Warning

Troubleshooting should only be attempted by competent personnel. All major repair, and calibration work should

be undertaken by a domnick hunter trained, qualified and approved engineer.

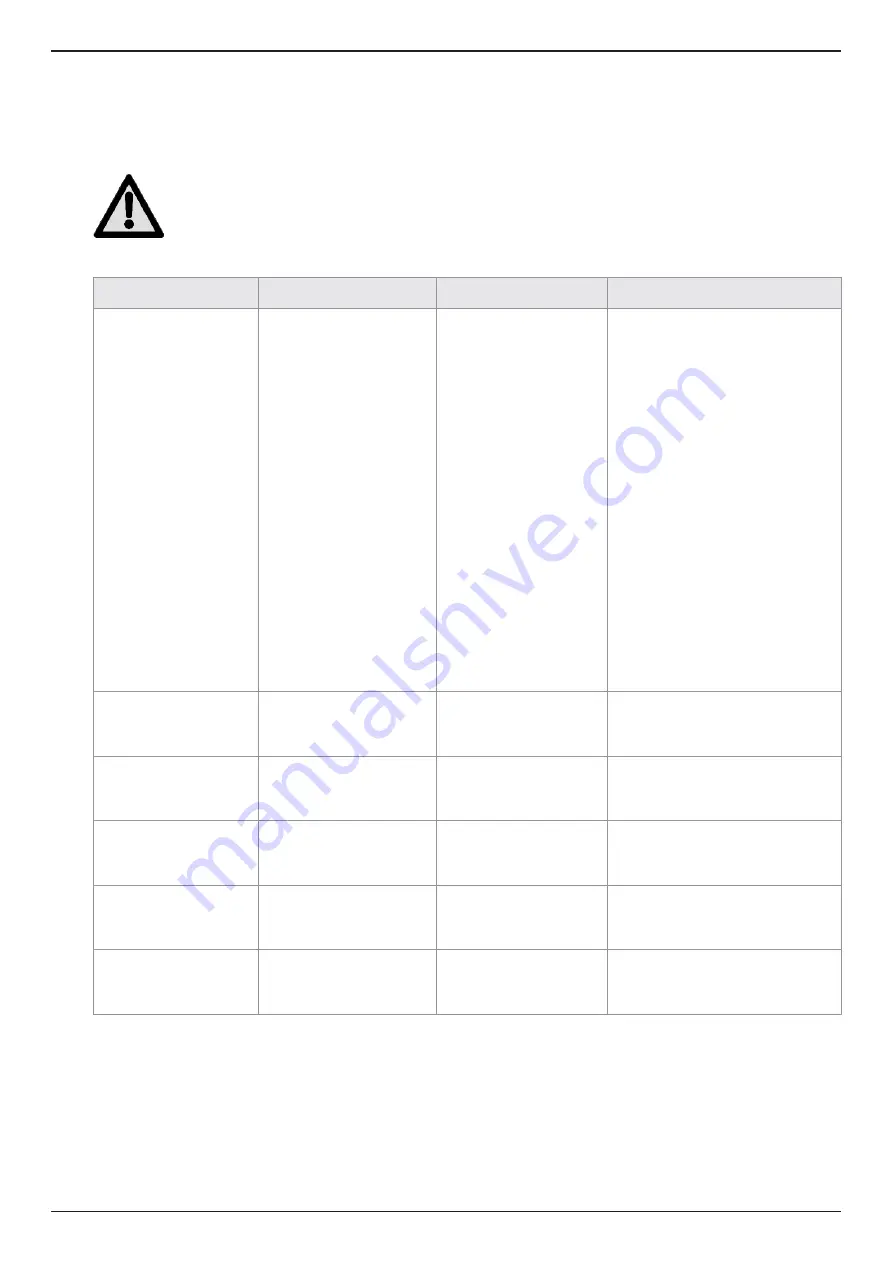

Problem

Indication

Probable Cause

Remedy

Poor dewpoint

Crystals go clear in the outlet

sight glass (DME040 - 080-RX

Models only)

Entrained Water

Excessive air flow demand

Inlet pressure too low

Excessive inlet air

temperature

Insufficient purge air flow

Exhaust silencers blocked

Contaminated desiccant

Check pre-filtration drains.

Check actual flow against rated flow of

dryer

Check for recent additions to air system

Check against technical specification

Check against technical specification

Factory set for 6 bar g (87 psig) system

pressure.

domnick hunter

trained personnel to

adjust

Change by

domnick hunter

trained

personnel

Eliminate source of contamination.

Desiccant change by

domnick hunter

trained personnel

Electrical fault

Flashing Yellow LED

Hardware fault

Contact

domnick hunter

customer

services

High differential pressure

Pressure gauges

Excessive outlet flow

Check and regulate air demand

Failure to purge

No depressurisation and poor

dewpoint

Purge valve blocked or shut.

Exhaust silencers blocked.

domnick hunter

trained personnel to

adjust.

Change by

domnick hunter

trained

personnel

Outlet air flow stops

Downstream pressure drops.

Yellow LED “OFF”

Electrical fault.

Blown fuse in plug.

domnick hunter

trained personnel to

adjust.

Change by

domnick hunter

trained

personnel

Constant depressurisation

Erratic air flow from exhaust

Damaged valve.

Change by

domnick hunter

trained

personnel