English

5/6

PSH120-630

6 Maintenance

a) Th

e machine is designed and built to guarantee continuous opera-

tion; however, the life of its components depends on the maintenance

performed;

b) when requesting assistance or spare parts, identify the machine

(model and serial number) by reading the data plate located on the

unit.

6.1 General instructions

!

Before any maintenance, make sure:

• the pneumatic circuit is no longer pressurized;

• the dryer is disconnected from the main power supply

.

Y

Always use the Manufacturer’s original spare parts: otherwise the

Manufacturer is relieved of all liability regarding machine malfunctio-

ning

Y

In case of refrigerant leakage, contact qualifi ed and authorized per-

sonnel.

Y

Th

e Schrader valve must only be used in case of machine malfun-

ction: otherwise any damage caused by incorrect refrigerant charging

will not be covered by the warranty.

6.2 Refrigerant.

Charging: any damage caused by incorrect refrigerant replacement car-

ried out by unauthorized personnel will not be covered by the warranty.

Z

Y

Th

e equipment contains fl uorinated greenhouse gases.

At normal temperature and pressure, the R407c refrigerant is a co-

lourless gas classifi ed in SAFETY GROUP A1 - EN378 (group 2 fl uid

according to Directive PED 97/23/EC)

GWP (Global Warming Potential) = 1774.

!

In case of refrigerant leakage, ventilate the room.

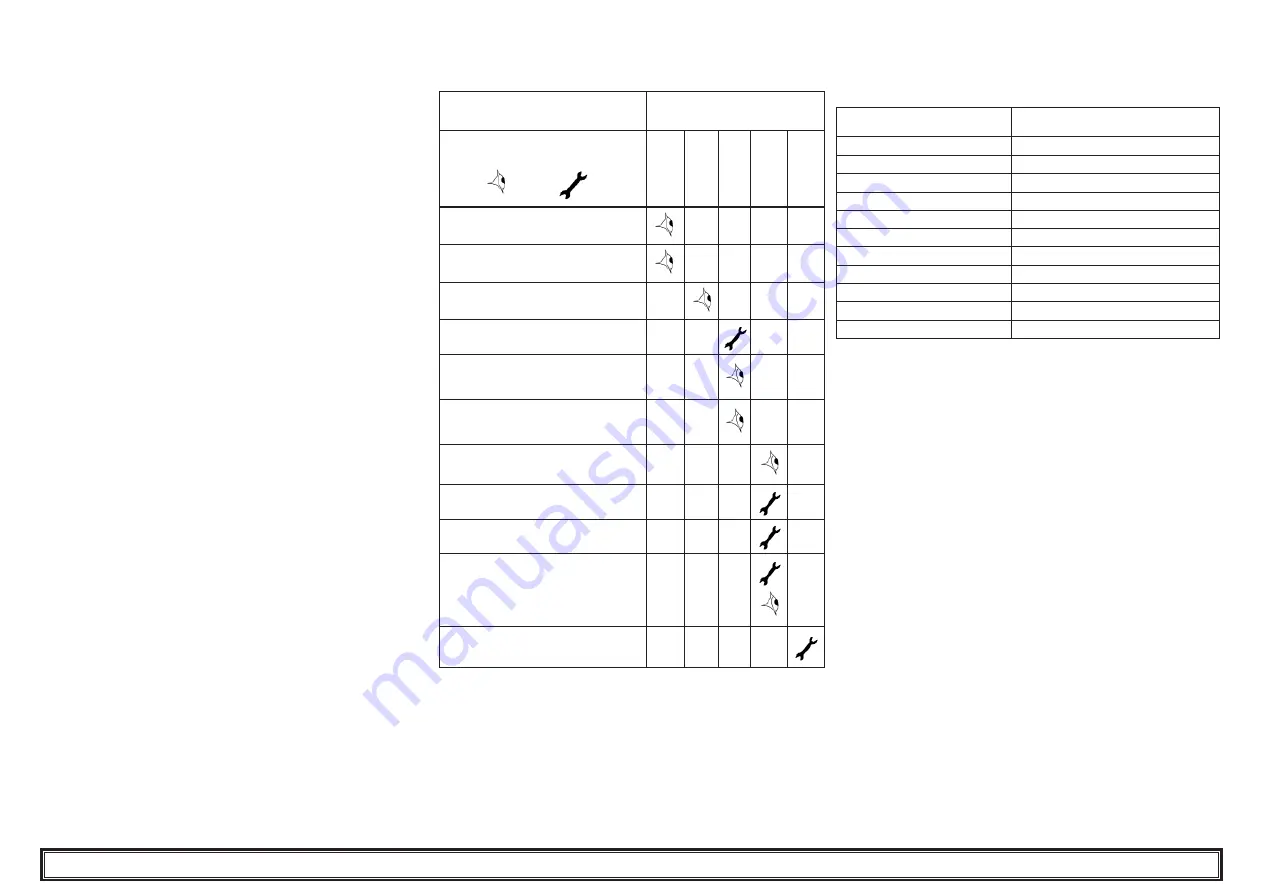

6.3 Preventive Maintenance Programme

To guarantee lasting maximum dryer effi

ciency and reliability

Maintenance

Activity Description

Maintenance Interval

(standard operating conditions

)

Activity

Check

Service

Da

ily

W

eek

ly

4 M

on

ths

12 M

on

ths

36 M

on

ths

Check POWER ON indicator is lit.

Check control panel indicators.

Check condensate drain.

Clean condenser fi ns.

Verify that the crakcase heater is cor-

rectly positioned

Check electrical absorption.

Check refrigerant leaks.

Depressurize the dryer. Complete

drain maintenance.

Depressurize the dryer. Replace pre-

and post-fi lter elements.

Check temperature sensors.

Replace if necessary.

Dryer maintenance kit.

Th

e following are available (see par. 8.4):

a) 3 years preventive maintenance kits;

b) service kit

• compressor kits;

• fan kits;

• hot gas valve kits;

• water condenser kits;

c) individual spare parts.

6.4 Dismantling

Th

e refrigerant and the lubricating oil contained in the circuit must be

recovered in conformity with current local environmental regulations.

%

Recycling Disposal

Z

structural work

steel/epoxy-polyester resins

exchanger

aluminium

pipes/headers

copper/aluminium/carbon steel

drain

polyamide

exchanger insulation

EPS (sintered polystyrene)

pipe insulation

synthetic rubber

compressor

steel/copper/aluminium/oil

condenser

steel/copper/aluminium

refrigerant

R407c

valves

brass

electrical cables

copper/PVC

Summary of Contents for Polestar-HP Smart PSH120

Page 2: ......

Page 28: ...8 5 EXPLODED DRAWING 8 PSH120 630 A B E D C 12 15 B3 4 5 1 8 3 9 2 B1 34 PSH 120 230 Ac ...

Page 29: ...8 5 EXPLODED DRAWING 9 PSH120 630 B A E D C 34 15 12 9 B3 1 2 2 3 8 4 5 B1 4 5 PSH 290 460 Ac ...

Page 31: ...8 6 DIMENSIONAL DRAWING 11 PSH120 630 34 15 9 B3 B E D C A 2 8 1 4 4 5 5 F G 22 B1 PSH 460 Wc ...

Page 33: ...8 6 DIMENSIONAL DRAWING 13 PSH120 630 PSH 120 230 Ac ...

Page 34: ...8 6 DIMENSIONAL DRAWING 14 PSH120 630 PSH 290 460 Ac ...

Page 35: ...8 6 DIMENSIONAL DRAWING 15 PSH120 630 PSH 630 Ac ...

Page 36: ...8 7 REFRIGERANT CIRCUIT 16 PSH120 630 PSH 290 460 Wc ...

Page 37: ...8 7 REFRIGERANT CIRCUIT 17 PSH120 630 PSH 630 Wc ...

Page 38: ...8 7 REFRIGERANT CIRCUIT 18 PSH120 630 PSH 120 230 Ac ...

Page 39: ...8 7 REFRIGERANT CIRCUIT 19 PSH120 630 PSH 290 460 Ac ...

Page 40: ...8 7 REFRIGERANT CIRCUIT 20 PSH120 630 PSH 630 Ac ...

Page 41: ...8 7 REFRIGERANT CIRCUIT 21 PSH120 630 PSH 490 460 Wc ...

Page 42: ...8 7 REFRIGERANT CIRCUIT 22 PSH120 630 PSH 630 Wc ...

Page 43: ...8 8 WIRING DIAGRAM 23 PSH120 630 Sheet 1 of 6 PSH 120 230 Ac ...

Page 44: ...8 8 WIRING DIAGRAM 24 PSH120 630 Sheet 2 of 6 PSH 120 230 Ac ...

Page 45: ...8 8 WIRING DIAGRAM 25 PSH120 630 Sheet 3 of 6 PSH 120 230 Ac ...

Page 46: ...8 8 WIRING DIAGRAM 26 PSH120 630 Sheet 4 of 6 PSH 120 230 Ac ...

Page 47: ...8 8 WIRING DIAGRAM 27 PSH120 630 Sheet 5 of 6 PSH 120 230 Ac ...

Page 48: ...8 8 WIRING DIAGRAM 28 PSH120 630 Sheet 6 of 6 PSH 120 230 Ac ...

Page 49: ...8 8 WIRING DIAGRAM 29 PSH120 630 Sheet 1 of 6 PSH 290 630 Ac ...

Page 50: ...8 8 WIRING DIAGRAM 30 PSH120 630 Sheet 2 of 6 PSH 290 630 Ac ...

Page 51: ...8 8 WIRING DIAGRAM 31 PSH120 630 Sheet 3 of 6 PSH 290 630 Ac ...

Page 52: ...8 8 WIRING DIAGRAM 32 PSH120 630 Sheet 4 of 6 PSH 290 630 Ac ...

Page 53: ...8 8 WIRING DIAGRAM 33 PSH120 630 Sheet 5 of 6 PSH 290 630 Ac ...

Page 54: ...8 8 WIRING DIAGRAM 34 PSH120 630 Sheet 6 of 6 PSH 290 630 Ac ...

Page 55: ...8 8 WIRING DIAGRAM 35 PSH120 630 Sheet 1 of 6 PSH 290 630 Wc ...

Page 56: ...8 8 WIRING DIAGRAM 36 PSH120 630 Sheet 2 of 6 PSH 290 630 Wc ...

Page 57: ...8 8 WIRING DIAGRAM 37 PSH120 630 Sheet 3 of 6 PSH 290 630 Wc ...

Page 58: ...8 8 WIRING DIAGRAM 38 PSH120 630 Sheet 4 of 6 PSH 290 630 Wc ...

Page 59: ...8 8 WIRING DIAGRAM 39 PSH120 630 Sheet 5 of 6 PSH 290 630 Wc ...

Page 60: ...8 8 WIRING DIAGRAM 40 PSH120 630 Sheet 6 of 6 PSH 290 630 Wc ...