© Panduit Corp. 2013

OPERATION MANUAL

PAT1M, PAT1.5M, PDM

ENGLISH

Page: 25 of 39

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off", and resume operation. If the

message remains, the system will not operate. Write down the message and notify the maintenance department.

PREVENTION:

Never adjust the PDM Dispenser internal regulator. Follow the maintenance schedule for regreasing

the piston.

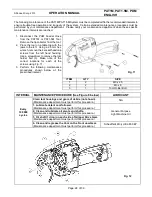

ERROR 15 - Internal regulator incorrectly set, high

Internal regulator incorrectly set, high

MENU

Buzzer

POSSIBLE CAUSE:

This error message appears if the PDM Dispenser internal regulator was adjusted incorrectly.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off", and resume operation. If the

message remains, the system will not operate. Write down the message and notify the maintenance department.

PREVENTION:

Never adjust the PDM Dispenser internal regulator.

7G: Functional Messages

Functional messages notify the operator about component malfunction and/or maintenance requirements. Like the

error messages, the operator is alerted that an error has occurred by two types of signals: a buzzer signal (audible)

and the dispenser display (visual). The dispenser display will indicate the possible problem that has occurred.

Depending on the nature of the problem, the system may not become operational until the system is serviced.

Problem 1 - No exit sensor seen - service tool soon

No exit sensor seen - service tool soon

MENU

Buzzer

POSSIBLE CAUSE:

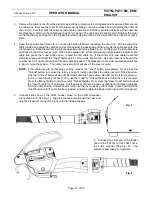

This message is displayed if there is a cable tie in the feeder hose at the time the tool is

actuated (at the start of the cycle), or, if the dispenser exit sensor is not functioning properly.

CORRECTIVE ACTION:

If this message appears, operation can be resumed immediately. If operation is resumed

and the same message is displayed, the dispenser exit sensor may be dirty, or it may not be functioning properly.

PREVENTION:

If this same error is repeated, the dispenser exit sensor lens may be cleaned with a cotton swab

dampened with isopropyl alcohol. Disconnect the feeder hose from the dispenser and insert the dampened end of

the cotton swab into the dispenser strap tube about 1.5" (38 mm) and gently move the cotton swab in and out,

against the top and bottom walls of the strap tube. If the same error is repeated again, notify your maintenance

department.

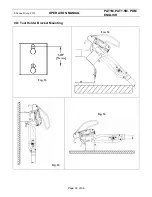

Problem 2 - Switch #X is stuck or broken

Switch #X is stuck or broken

POSSIBLE CAUSE:

This message will appear if a switch (button #1, 2, 3, 4, or the trigger) is held down or stuck

when the dispenser is turned "on". This message will also appear if one of these five switches has malfunctioned.

The specific switch (button) that was held down or that has malfunctioned will be displayed at the beginning of the

message.