36

37

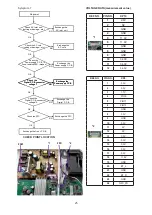

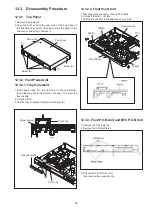

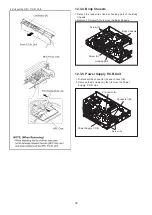

12.3.4. Body Chassis

1.Detach the lead wires fixed at hooking part of the Body

Chassis.

2.Remove 3 Screws (A) to remove the Body Chassis

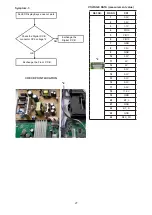

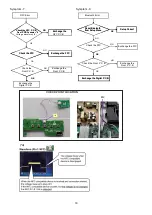

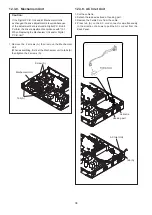

12.3.5. Power Supply P.C.B.Unit

1. Disconnect the connector (A) and connect (B).

2. Remove the 2 screws (A), then remove the Power

Supply P.C.B. Unit.

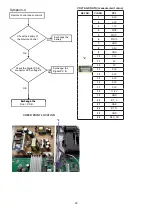

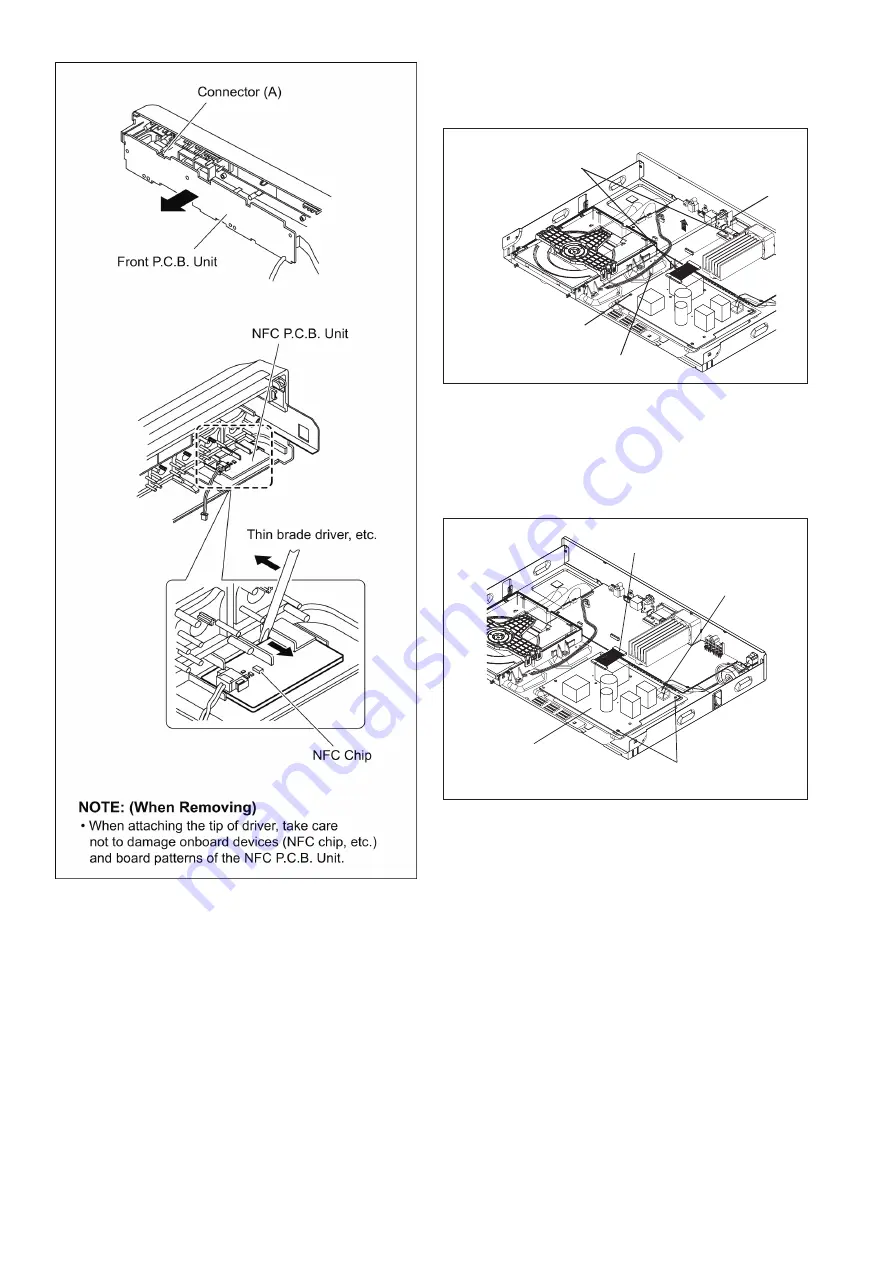

4. Pull out the NFC P.C.B. Unit..

37

4. Pull out the NFC P.C.B. Unit.

12.3.4. Body Chassis

1. Detach the lead wires fixed at hooking part of the Body

Chassis.

2. Remove the 3 screws (A) and remove the Body Chassis.

12.3.5. Power Supply P.C.B. Unit

1. Remove the connector (A) and (B).

2. Remove the 2 screws (A), then remove the Power Supply

P.C.B. Unit.

Screw (A)

Screw (A)

Body Chassis

Connector (A)

Connector (B)

Power Supply P.C.B.

Hooking part

Screw (A)