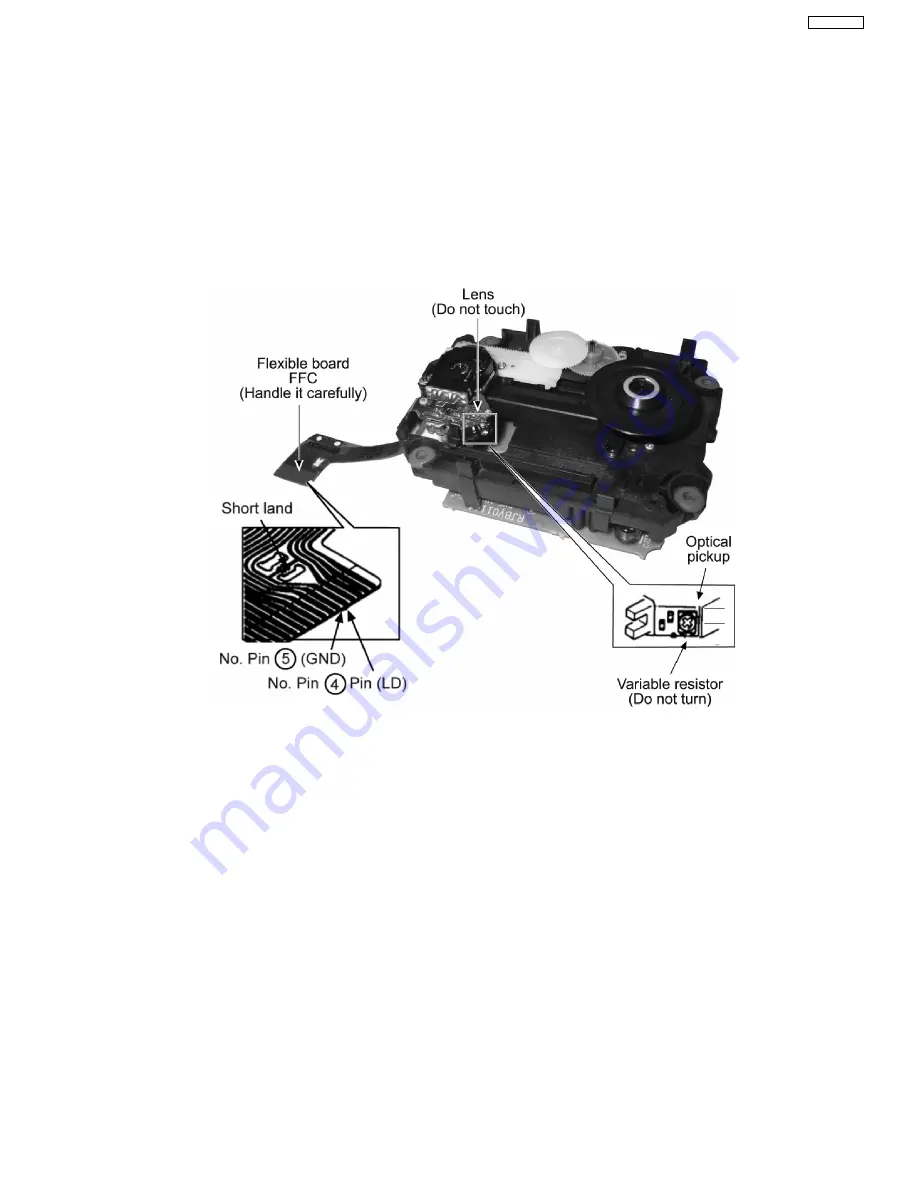

3 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by the static electricity of

clothes or our human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

·

Way of handling the traverse deck (optical pickup)

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. To prevent the breakdown of the laser diode, an antistatic shorting pin is inserted into the flexible board (FFC board).

3. Do not to apply excessive stress to the flexible board (FFC board). When removing or connecting the short pin, finish the job

in as short time as possible.

4. Do not turn the variable resistor for laser power adjustment. (It is pre-adjusted during production time)

Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is place, and ground the

sheet.

Caution :

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when replacing the Traverse Deck

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

7

SA-AK450PL

Summary of Contents for SA-AK450PL

Page 8: ...8 SA AK450PL ...

Page 11: ...6 Accessories Remote Control FM Antenna Wire AC Cord AM Loop Antenna 11 SA AK450PL ...

Page 12: ...7 Operating Instructions Procedures 7 1 Main Unit Key Buttons Operations 12 SA AK450PL ...

Page 13: ...7 2 Remote Control Key Buttons Operations 13 SA AK450PL ...

Page 26: ...10 3 Main Parts Location 26 SA AK450PL ...

Page 38: ...10 17 1 Replacement of Pinch Roller and Head Block 38 SA AK450PL ...

Page 39: ...10 17 2 Replacement of Motor Capstan Belt A Capstan Belt B and Winding Belt 39 SA AK450PL ...

Page 45: ...12 4 Checking and Repairing of Power P C B 45 SA AK450PL ...

Page 47: ...47 SA AK450PL ...

Page 51: ...15 3 Main P C B 15 4 Panel P C B 51 SA AK450PL ...

Page 52: ...15 5 Power P C B Transformer P C B 52 SA AK450PL ...

Page 53: ...15 6 Waveform Chart 53 SA AK450PL ...

Page 62: ...SA AK450PL 62 ...

Page 64: ...64 SA AK450PL ...

Page 84: ...SA AK450PL 84 ...

Page 89: ...23 Exploded Views 23 1 Cabinet Parts Location SA AK450PL 89 ...

Page 90: ...SA AK450PL 90 ...

Page 91: ...23 2 Deck Mechanism Parts Location RAA4403 S SA AK450PL 91 ...

Page 92: ...23 3 Packaging SA AK450PL 92 ...