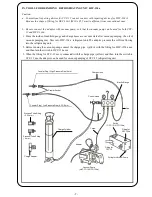

7. ASSEMBLING THE COMPRESSOR AND THE DRYER

General Clause

a. It should be finished within 30 minutes.

When pipe purging no need

When pipe purging has need

b.

c. The Dryer just special for HFC-134a refrigerant only.

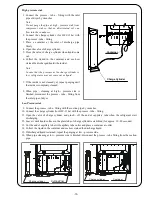

Assembling Compressor

1.

a

a

2.

3.

a.

b.

4.

5.

6.

7.

8.

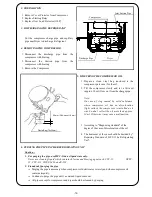

Replacement Standard of Dryer

1.

2.

3.

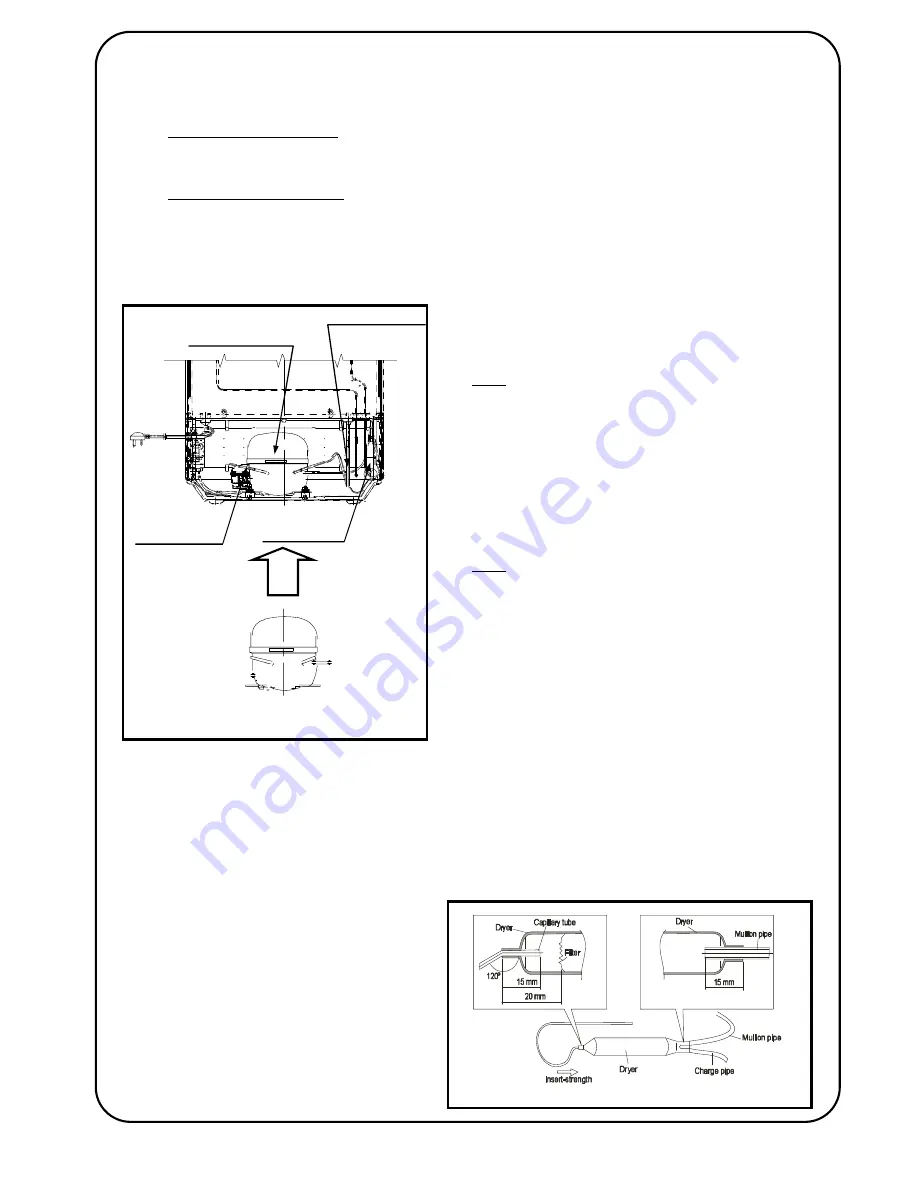

Bend the capillary tube at an obtuse angle of about 120

o

along 15mm from the cut end before inserting the

tube into the dryer. Then insert the tube until it is stopped by the bend. This is to prevent the tube from going

into the dryer too far and breaking the filter placed inside. Also this insure that the tube goes into the dryer far

enough not to be clogged with the filler metal during brazing.

Insert the capillary tube ±15mm into the

dryer.

Break the package of dryer just before use.

This is to prevent dryer from absorbing

moisture in the air. If the package is bruise,

as air has leakage into the package, never use

the dryer in the package.

use dryer within the term of validity (which is

marked in the package).

Joint capillary tube, Mullion dryer pipe and Charge pipe (Dia. 4 mm) to Draye with brazing.

If there is no sound of discharging gas, never use

the compressor.

Take out the dryer from the package just before use.

Joint the suction pipe and compressor with brazing.

Note:

Set the compressor in the compressor room.

D joint must place in compreesor room at Cooling

unit.

From the process of removing compressor until the process of setting compressor and dryer (just

before vacuum pumping process).

From the time just after pipe cleaning is completed until the process of setting compressor and dryer

(just before vacuum pumping process).

If pipe are being kept open to air, moisture will go into the refrigerating unit and it may cause a

malfunction in the refrigerating unit again.

Note:

Joint the gascharge pipe with brazing.

Remove rubber caps of compressor just before

compressor is installed.

Joint the discharge pipe and compressor with brazing.

Check the sound of discharging gas from the

compressor when rubber caps are removed.

Shape and length of pipe must be suitable with

Discharge pipe.

Dryer

Discharge

Compressor

Joint Suction

Compressor

-14-

Summary of Contents for NR-B203G-S7

Page 10: ... 9 ...

Page 22: ...1 Part Structure 1 2 LIST OF SPARES PARTS INDICATED SAFETY PART 52 90 91 19 ...

Page 23: ...PMIRF0806022AI 1 2 Part Structure 2 2 20 ...

Page 26: ... 22 ...