6

2.3.

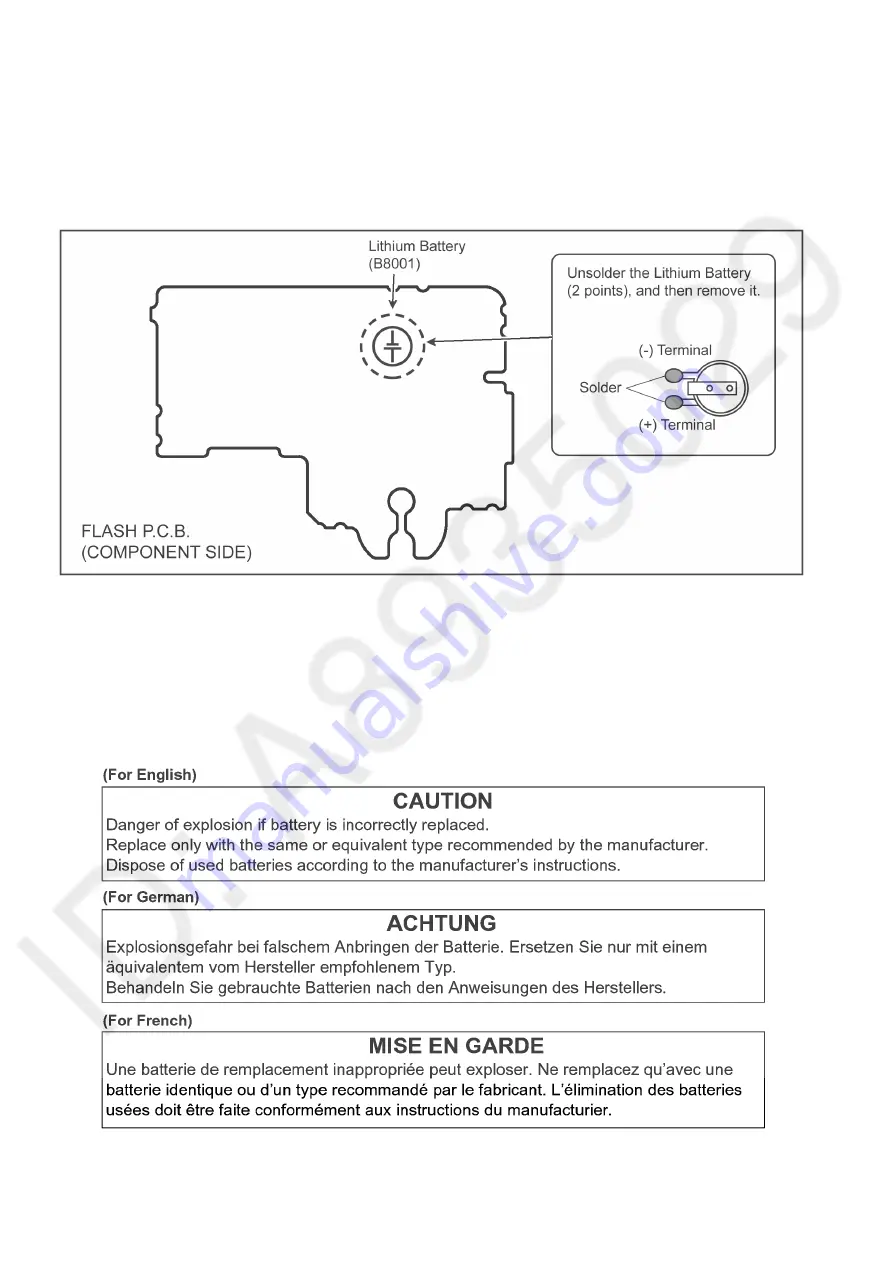

How to Replace the Lithium Battery

2.3.1.

Replacement Procedure

1. Remove the Flash P.C.B.. (Refer to Disassembly Procedures.)

2. Unsolder the each soldering point of electric lead terminal for Lithium battery (Ref. No. "B8001" at component side of Flash

P.C.B.) and remove the Lithium battery together with electric lead terminal. Then replace it into new one.

NOTE:

The Lithium battery includes electric lead terminals.

NOTE:

This Lithium battery is a critical component.

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in requirement designed specifically for its use.

Replacement batteries must be of same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for DMC-FZ300/FZ330 series, as well.

Summary of Contents for DMC-FZ300PP

Page 17: ...17 ...

Page 18: ...18 ...

Page 20: ...20 ...

Page 29: ...29 9 3 1 Removal of the Rear Case Unit Fig D1 Fig D2 ...

Page 30: ...30 Fig D3 Fig D4 ...

Page 31: ...31 Fig D5 9 3 2 Removal of the Main P C B Fig D6 ...

Page 32: ...32 Fig D7 9 3 3 Removal of the Top Case Unit and Battery Case Unit Fig D8 ...

Page 33: ...33 Fig D9 Fig D10 ...

Page 34: ...34 Fig D11 Fig D12 ...

Page 37: ...37 Fig D18 Fig D19 ...

Page 40: ...40 9 3 13 Removal of the LCD IF P C B MR Sensor FPC and LCD Unit Fig D24 Fig D25 ...

Page 43: ...43 9 4 3 Removal of the Zoom Motor 1 Unscrew the 2 screws C ...

Page 58: ...58 ...

Page 59: ...59 ...

Page 60: ...60 ...

Page 64: ...64 ...