8

Palmgren Operating Manual & Parts List

84112

MAINTENANCE (CONTINUED)

•

Using a clean, dry cloth, clean all of the chains and gears of

wood chips, dust, and old grease.

LUBRICATION

•

The table surface can be coated with a lubricant, such as paste

wax, to make the workpiece feed smoother. Be sure that the

lubricant used does not affect the ability to finish the work-

piece with varnish, sealer, etc.

For example, do not use any silicone base lubricants because

they will ruin any attempt to finish the wood.

•

Use common automotive bearing grease to lubricate all chains

and gears. Be sure all chains and gears have plenty of grease.

•

Motor and cutterhead bearings are sealed and need no lubrication.

CHECK FOR WORN BLADES

•

Condition of blades affects precision of cut. Observe quality of

cut which planer produces to check condition of blades.

•

Dull blades tear, rather than sever wood fibers and produce

fuzzy appearance.

•

Raised grain occurs when dull blades pound on wood that has

varying density. Raised edge will also be produced where

blades have been nicked.

REPLACE BLADES

Refer to Figures 14 - 16.

WARNING:

Always turn planer OFF and disconnect from power

source before starting any maintenance work.

NOTE: Always reverse or replace both blades as a set.

•

Remove return rollers.

•

Loosen and remove socket head bolts from blade guard on the

rear side of planer. Remove blade guard.

•

Carefully turn cutterhead by hand towards you until bolts are

accessible.

•

Loosen and remove six bolts from gib.

•

Remove gib using magnets provided.

NOTE: Magnets can be easily disengaged from gib by tilting them

to left or right.

CAUTION:

Blade edges are extremely sharp. Keep fingers away

from blades at all times.

•

Blade is located in position by two pins. Carefully lift old blades

from the cutterhead using the two magnets. Do not make con-

tact with the blade using fingers. Use magnets only.

NOTE: Magnets can be easily disengaged from blade by tilting

them to left or right.

•

Reverse or replace blade and carefully position it on the two

pins using the magnets.

•

Replace gib and align the holes on the gib with holes on the

blade using magnets.

•

Secure gib to cutterhead using six bolts removed earlier.

•

Carefully turn cutterhead by hand until the other blade is accessi-

ble.

•

Remove gib and blade as mentioned earlier.

•

Replace with new blade and replace gib and secure it as men-

tioned earlier.

•

Replace blade guard and secure it using two bolts.

ADJUSTING ROLLERCASE LEVEL

Refer to Figure 17, page 9.

The planer will produce an uneven depth of cut (tapered cut) if

rollercase is not parallel with base. To restore parallelism of roller-

case with base:

•

Using a test piece, measure height of the taper. Determine

which corner or side needs adjustment.

•

Turn planer off and disconnect from power source.

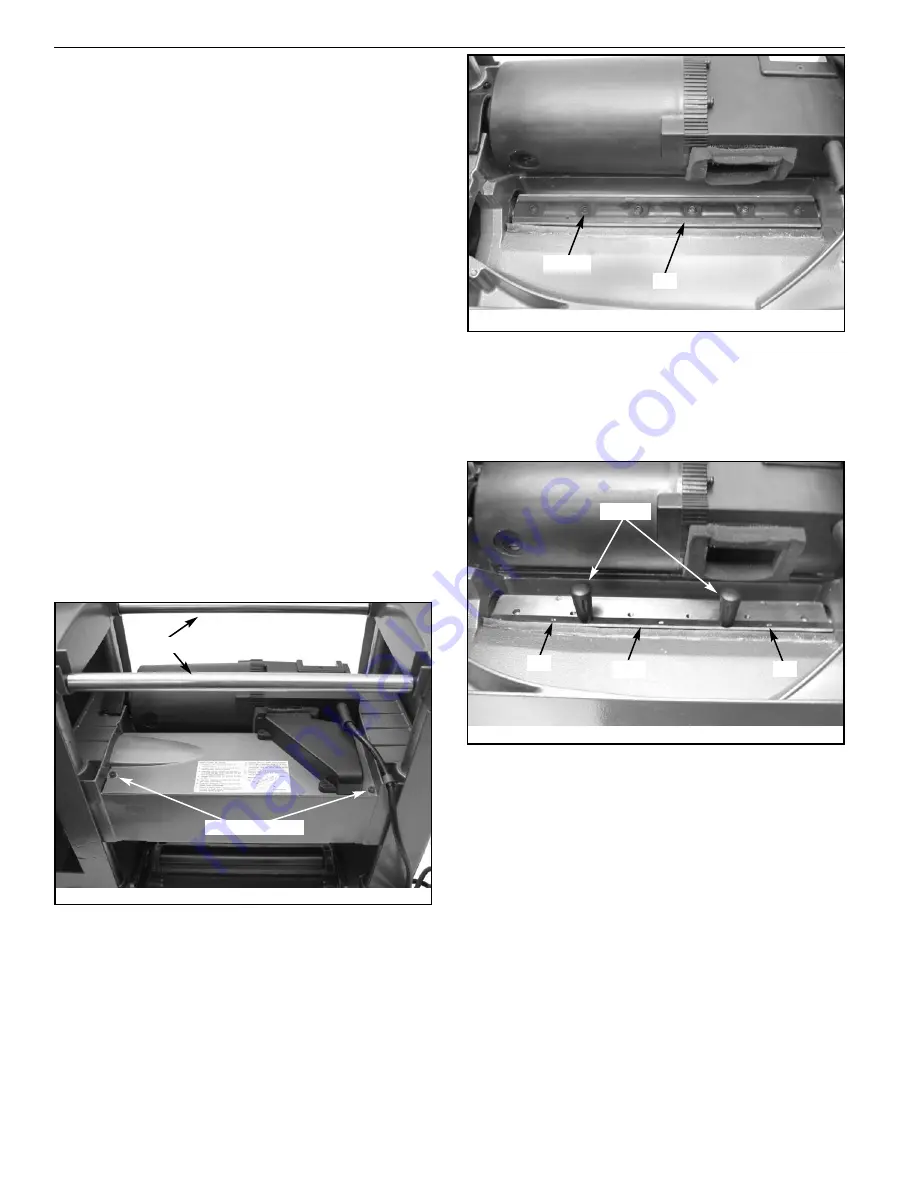

Figure 14 – Remove Blade Guard

Return Rollers

Socket Head Bolts

Gib

Bolts (6)

Figure 15 – Removing Gib

Pin

Pin

Blade

Magnets

Figure 16 – Removing Blade