UR620/40/60/80

UR620/40/60/80 Series

RETURN LINE FILTERS

s e r v i c e

i n s t r u c t i o n s

3

ENGLISH

4.8

Ensure the valves immediately upstream and downstream of

the filter assembly are closed. Commission filter assembly as

follows:

NOTE: For UR640, 660 & 680 units, the following procedure

applies to each housing.

(a)

Ensure that drain and commuter valves are closed.

(b)

Open left hand housing vent port.

(c)

Open commuter valve (three full turns max) purge all air (16).

(d)

Position change-over valve to the left, to allow flow through

left hand housing.

(e)

Bleed filter by opening the vent plug (10) on the cover (5) of

the filter one and one half turns. Jog system and fill filter until

all air bleeds through the plug (filter can be optionally filled

using the fill port (12)), then tighten plug. Close commuter

valve (16). Pressurize system fully and check for leaks; if

leaks occur refer to section 5.

(f)

Open right hand housing vent port and commuter valve.

(g)

Open commuter valve (three full turns max) purge all air (16).

(h)

Position change-over valve to right, to allow flow through

right hand housing. Close vent port when bubble free fluid

issues from port and torque tighten to 12 ft/lb or 16 Nm.

Close commuter valve (16).

(i)

Fully pressurise and check for leaks. If any leak is apparent

shut down, depressurise and rectify leak before proceeding.

(j)

On completion of test sequence, position change-over valve

to place selected housing on stream.

NOTE: Cover the visual warning device and nameplate if

painting of the assembly takes place.

5

Routine maintenance

5.1

Pall filters do not normally require special attention except

for periodic monitoring of the differential pressure warning

device. Schedule replacement of filter element every six

months or sooner, and have ample supply of spare elements

available.

5.2

If external leakage is noted, replace O-ring at leak. If leakage

persists, check sealing surfaces for scratches or cracks;

replace any defective parts. Body assembly is permanently

assembled at the factory: do not attempt to disassemble the

head (1), body tube (2), center post (3), change-over valve (14)

or check valve (15).

5.3

Differential pressure devices actuate when the filter element

(8) needs changing or because of high fluid viscosity in ‘cold

start’ conditions. If ‘cold start’ conditions exist, see Section

6.2 and 6.3.

5.4

A dirty system can quickly plug a new filter element,

especially with Pall high efficiency filter media. It may require

one or two initial element changes to stabilize element life.

If element life is short or differential pressure is excessive,

filter may be undersized; refer to the sizing and selection

section of the product literature or contact your local Pall

representative.

5.5

Make sure element change labels are clean and undamaged.

Replace illegible labels with the appropriate new labels.

6

Differential pressure devices

Reference should be made to product literature for dimensions,

operating parameters, part numbering, ordering information and

specifications.

6.1

Differential pressure devices actuate when the element needs

changing or because of high fluid viscosity in ‘cold start’

conditions.

6.2

If visual indicator is fitted and actuates during ‘cold start’

(indicates red), reset by depressing the button when the

normal operating temperature is reached. If indicator actuates

after resetting, replace element.

NOTE: Option ‘P’ visual indicator has thermal lockout and manual

reset.

No signal below 0 °C (32 °F), signal above 27 °C (80 °F).

6.3

If the electrical switch actuates (e.g. red light comes on)

during cold start, continue operating until the signal (red light)

goes out as system warms to normal operating temperature.

This feature can be used as ‘warm up’ indication in operating

procedures. If the warning signal (red light) remains or appears

when system is warm, replace the filter element.

6.4

Use of both positive indication (green light) and negative

indication (red light for dirty element) is recommended to

effectively monitor filter element life.

Electrical connections and ratings for all differential

pressure switch options:

110 VAC

=

4A (inductive),

4A (resistive)

220 VAC

=

4A (inductive),

4A (resistive)

28 VDC

=

3A (inductive),

5A (resistive)

48 VDC

=

1A (inductive),

1.5A (resistive)

125 VDC

=

0.25A (inductive),

0.5A (resistive)

Maximum inrush - 24 amps.

Underwriter’s lab. Inc. listed ratings of pressure switch (Microswitch)

options are:

4 amps at 250 VAC

0.25 amp resistive at 220 VDC

0.50 amp resistive at 110 VDC

Electrical differential pressure switch operation:

When preset differential pressure is exceeded continuity switches from

Normally Closed (NC) - Common to Normally Open (NO) - Common.

When differential pressure decreases below pre-set value, continuity

returns to Normally Open (NO) - Common to Normally Closed (NC) -

Common.

See individual indicator options for connection details.

CAUTION:

Failure to bleed the filter housing adequately will

increase the dissolved air content of the system fluid

which will shorten fluid life and may cause other

problems in the system.

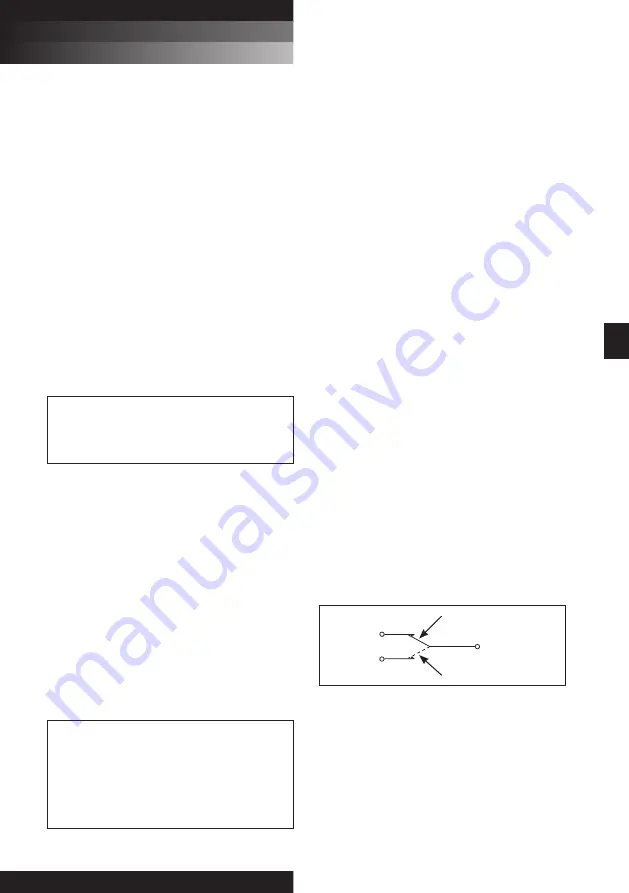

Figure 1

- Stainless Steel

Switch Circuit Diagram

CAUTION:

Continued operation of 620 series bypass filters (valve

options A, B and G), with differential pressure device

actuated, can allow unfiltered flow downstream.

Continued operation of 620 series non-bypass filters

(valve options W or N may cause collapse or premature

fatigue failure of the plugged filter element, which could

allow contaminant and unfiltered flow downstream.

Refer to element change instructions in section 7.

7

Filter element servicing

During servicing, the external surfaces of the filter assembly must be

cleaned to remove any dust deposits.

Servicing must be conducted using suitable tools that do not present

a hazard.

Servicing must not be carried out when a potentially explosive

atmosphere is present.

COMMON

NORMALLY

CLOSED (NC)

NORMALLY

OPEN (NO)

LOW DIFFERENTIAL PRESSURE

HIGH DIFFERENTIAL PRESSURE