15

51-4771

OPERATION

CONTROLS

STARTING AND STOPPING THE SWEEPER

The Pick-Up Sweepers use the prime mover hydraulic flow to operate. To start the

brush, turn on the prime mover auxiliary hydraulics. To stop the brush, turn off the auxiliary hy-

draulic flow. To avoid motor damage, do not stop the sweeper at high engine speed. Decrease

engine RPM before turning off the hydraulic flow.

TRAVEL DIRECTION

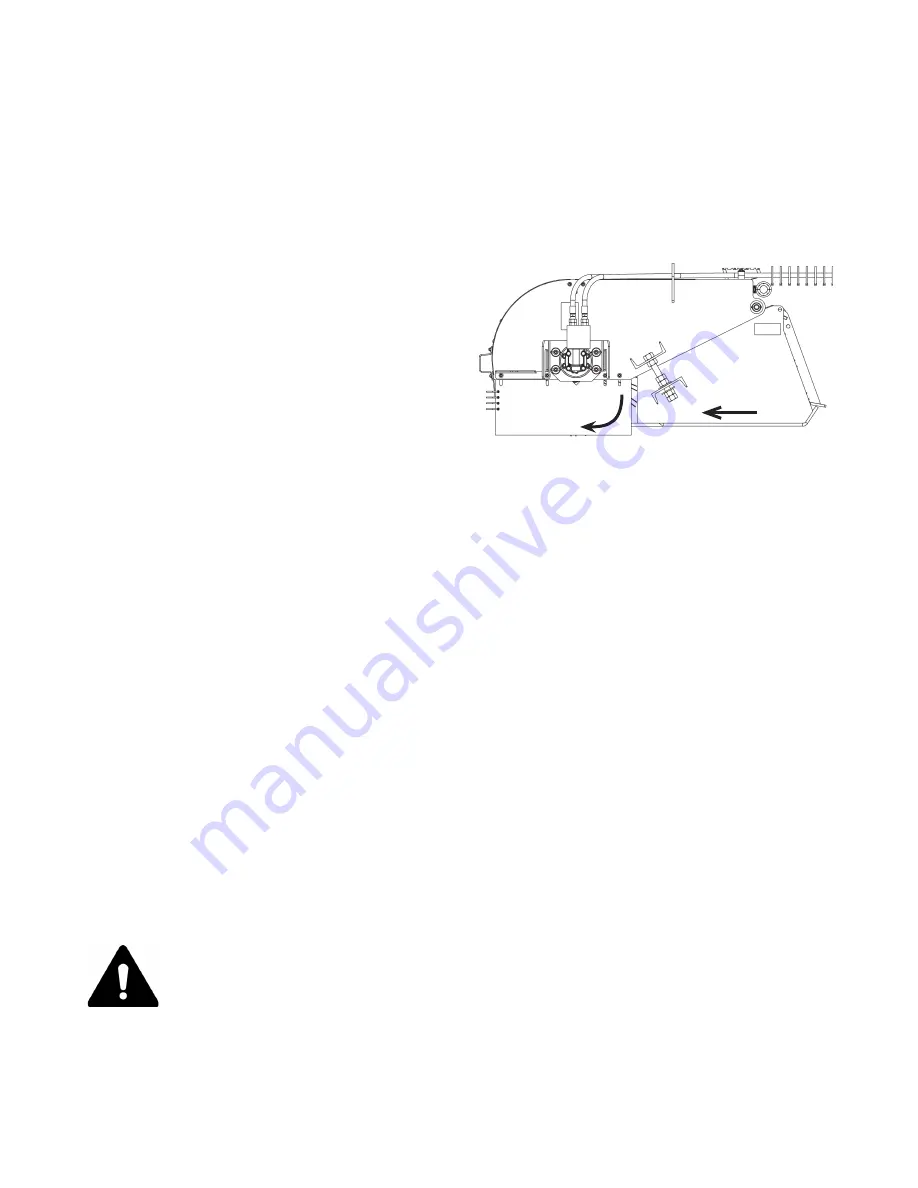

Travel should be in the forward direc-

tion and brush rotation always away from the

operator. The sweeper can reverse the brush

rotation for end of pass pile clean up or stuck

on material.

END OF PASS - PILE CLEAN UP

During normal sweeping operation, a small pile of material is pushed along in front of

the sweeper. End of pass clean up is one of the two reasons the brush rotation can be re-

versed. Using reverse mode for normal sweeping will NOT clean as well and will result in

premature wear.

To clean up this pile at the end of the sweeping pass, throttle down the prime mover,

drop the bucket cutting edge to the ground, and change the hydraulic flow (reversing brush

rotation) and inch forward. This will wisp the small pile of debris into the bucket (similar to that

of a broom and dust pan).

NOTE: Do not forget to lift the bucket approximately 1” and change broom rotation to

the forward direction after pile clean up.

DUMPING

Empty the bucket by raising the sweeper above the container, then dump using the prime mov-

er tilt controls.

WARNING! EXPOSURE TO RESPIRABLE CRYSTALLINE SILICA

DUST ALONG WITH OTHER HAZARDOUS DUSTS MAY CAUSE SERIOUS

OR FATAL RESPIRATORY DISEASE.

It is recommended to use dust suppression, dust collection and if necessary

personal protective equipment during the operation of any attachment that may

cause high levels of dust.

BRUSH SPEED

To increase brush speed, increase prime mover RPM. Use the LOWEST speed needed

to complete the job at hand. In general, half throttle provides the necessary engine speed.

DIRECTION OF TRAVEL

BRUSH

ROTATION