10

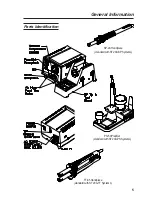

Set-Up

PaceLink

The PaceLink Receptacle on the front panel of

the power source allows the operator to activate

the AUTO SNAP-VAC and Controllable

PRESSURE features of a ST 60 system power

source. If an air handpiece (SX-70, TP-65 or

TJ-70) is connection to the ST 20A, actuation of

its finger switch will activate air flow through

the AUTO SNAP-VAC and Controllable

PRESSURE ports of the ST 60 system. To link

your ST 20A system to a ST 60 system, perform

the following procedure.

1. The 2 systems should be positioned

adjacent to each other. They can be placed

side by side or may be stacked one on top

of the other. Place your ST 20A system

beside or stack with your ST 60 system.

2. Use a PaceLink cable (available from

your local PACE distributor) to connect

the systems. Place the plugs on the ends

of the cable into the PaceLink

Receptacles on both systems.

3. Ensure that a VisiFilter assembly is

connected to the ST 60 AUTO SNAP-

VAC Port.

4. Connect the Air Hose of the handpiece

currently in use to the VisiFilter assembly

or Controllable PRESSURE Port.

CAUTION

Systems connected together through the PaceLink must be used and controlled

by a single operator. Any attempt to operate by more than one individual can

create a hazard condition and will cause a deterioration in performance.

Ensure that only one air hose is connected to the AUTO SNAP-VAC or

Controllable PRESSURE port at one time. Attachment to both ports

simultaneously will cause a deterioration in performance.

Summary of Contents for 20A

Page 1: ...Operation Maintenance Manual ST 20A Systems ...

Page 26: ...24 ...