TROUBLESHOOTING

Disconnect the welding power source from the mains supply voltage

before disassembling. Welding equipment should be regularly checked

by a qualified electrical trades person to ensure that:

• The main earth wire of the electrical installation is intact.

•

The power point for the welding power source is effectively earthed

and of adequate current rating.

•

Plugs and cord extension sockets are correctly wired.

•

Flexible cord is of the 3-core tough rubber or plastic sheathed type of

adequate rating, correctly connected and in good condition.

• Welding terminals are shrouded to prevent inadvertent contact or

short circuit.

•

The frame of the welding power source is effectively earthed.

• Welding leads and electrode holder are in good condition.

• The welding power source is clean internally, especially from metal

filing, slag, and loose material. If any parts are damaged for any

reason, replacement is recommended.

• Prior to operation, use the terminal spanner to securely tighten the

terminal knobs.

•

Cleaning the Drive Rolls

Clean the grooves in the drive rolls frequently. This can be done by

using a small wire brush. Also wipe off, or clean the grooves on the

upper drive roll. After cleaning, tighten the drive roll retaining screws.

Note:

Ozito Industries will not be responsible for any damage or

injuries caused by the repair of the tool by an unauthorised person or

by mishandling of the tool.

This product is classified as Group 2, Class A welding equipment.

• Group 2 - This product generates radio frequency energy in the

frequency range 9KHz to 400GHz.

• Class A - This product is intended for use in an industrial

environment.

Caution:

This equipment is not intended for use in

residential environments and may not provide adequate protection

to radio reception in such environments.

MAINTENANCE

EQUIPMENT CLASSIFICATION

OPERATION

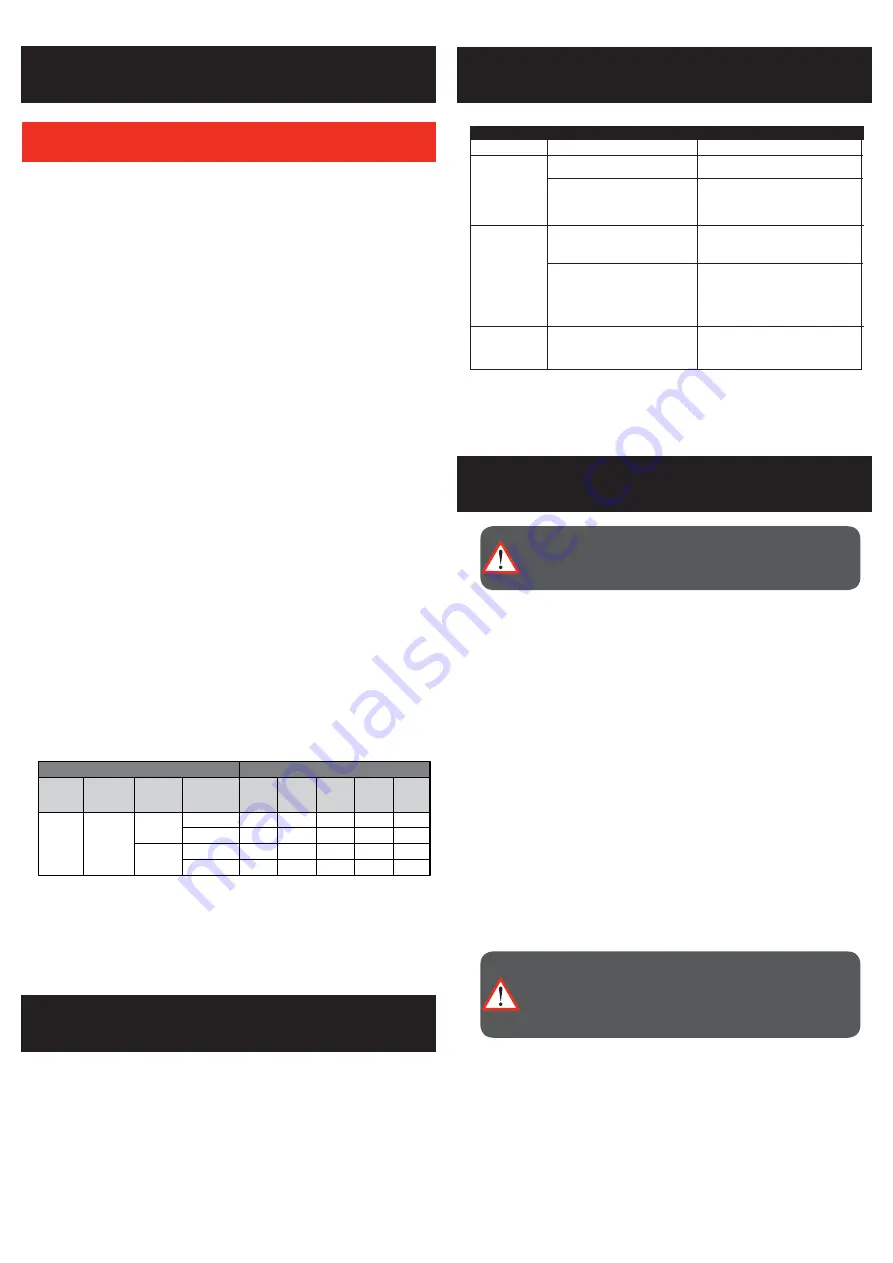

8. WELDING PROPERTIES

There are a range of welding movements used in MIG welding. Generally some

form of zig-zag motion is used to ensure the arc acts against both sheets to be

welded. Below are some details that may help with the welding process.

Travel Speed

The torch should be moved along at a smooth speed that will give the size of run

required. At the same time, the wire is fed downwards to keep the correct welding

distance at all times. Excessive travel speeds lead to poor fusion and lack of

penetration. While too slow a rate of travel may damage the work piece and can

lead to burning a hole through the material.

Electricity

The electricity flows through the wire and will not leave the wire unless it is near

an earthed object.

Electricity always finds the fastest path to the earth. When the earth cable clamp

is connected to the metal work piece a direct earth connection is created back to

the welder. When the wire touches or is near the earthed work piece when the

trigger is squeezed, electricity flows through the wire, the metal work piece and

then through the earth cable straight back to the welder.

Earth Clamp

Prior to connecting the earth clamp it may be necessary to clean the surface of

the work piece using the metal brush. Attach the earth clamp firmly to the work

piece ensuring there is good metal to metal contact. Clamp it where it will not be

in the way. This clamp provides an earth connection back to the welder.

Welding Wire

There are many variables that you will need to take into account when choosing

your welding wire size and type. Below are some of the things you need to take

into account when choosing the welding wire:

• Thickness of the material to be welded

• Position and type of welding joint

•

Maximum welding capacity of your welder

• How much penetration will be required for strength

• Type of bead desired for the weld

• Whether you are using a shielding gas or not

• Type of material to be welded

The above chart is only intended to show general guidelines for different wire

sizes and for different thicknesses of material. The settings should only be used

at the beginning of a weld and must be adjusted after stopping and carefully

inspecting the weld. Proper welding takes good technique and practice.

Flux Core Arc Welding

Material Thickness

MIG Welding

Material Thickness

Material

Being

Welded

Material

Being

Welded

Suggested

Shielding

Gas

Solid

Wire

Diameter

Suggested

Shielding

Gas

Suggested

Settings

Suggested

Settings

FCAW

Wire

Diameter

1.2mm

1.5mm 2.0mm 3.0mm 6.0mm

1.2mm

1.0mm

1.5mm 2.0mm 3.0mm 6.0mm

Steel

Steel

75% Argon

+25% CO

²

6-8L / MIN

75% Argon

+25% CO

²

8-10L / MIN

0.8

40

40

70

40

40

70

70

40

40

70

70

90

120

90

120

40

40

70

90

120

0.9

0.6

0.8

NO

GAS

Required

Current (A)

Wire Speed

Current (A)

Wire Speed

Current (A)

Wire Speed

Current (A)

Wire Speed

3~4

7~8 7.5~8 9~9.5 9.5~10

4~5

5~6

6~7

8~9

3~4

4~5

5~6

6~7

4~5

5~6

6~7

7~8

8~9

9~10

8~9

WELD SETTINGS CHART

PROBLEM

CAUSE

REMEDY

GENERAL OPERATION

No Power

Power supply

Test supply with another product, avoid using

extension leads.

Circuit breaker tripped

Check the rating of the curcuit breaker on the supply

and other appliances connected to the circuit.

The welder is a high power device and it is

recommended that is be the only appliance on the

circuit to ensure it has enough power to operate.

Welder feeding

incorectly

Wire roller wheel slipping

Increase the pressure on the pressure roller by

rotating the adjustable pressure screw in a

clockwise direction

Wire roller is applying too much pressure to

the wire

Decrease the pressure on the pressure roller by

rotating the adjustable pressure screw in an

anti-clockwise direction

Welder cuts out

Thermal overload active

The thermal overload light on the front panel will

be on and the welder will not operate until cooled

down and the light goes out. This is normal in heavy

welding, allow the welder to cool down.

WARNING:

THERE ARE EXTREMELY DANGEROUS VOLTAGE

AND POWER LEVELS PRESENT INSIDE THIS PRODUCT. DO NOT

ATTEMPT TO OPEN OR REPAIR UNLESS YOU ARE A QUALIFIED

ELECTRICAL TRADES PERSON.

CAUTION:

DO NOT USE COMPRESSED AIR TO CLEAN THE

WELDING POWER SOURCE. COMPRESSED AIR CAN FORCE

METAL PARTICLES TO LODGE BETWEEN LIVE ELECTRICAL

PARTS AND EARTHED METAL PARTS WITHIN THE WELDING

POWER SOURCE. THIS MAY RESULT IN ARCING BETWEEN THE

PARTS AND THEIR EVENTUAL FAILURE.