5. WELDING PROPERTIES

4. WELDED JOINTS

IWA-100

Arc Length

To strike the arc, the electrode should be gently scraped on the work until the arc

is established. A simple rule for the proper arc length; it should be the shortest

arc that gives a good surface to the weld. A very long arc produces a crackling

or spluttering noise and the weld metal comes across in large, irregular blobs

and gives a rough surface finish to the weld. A short arc is essential if a high

quality weld is to be obtained but a excessively short arc will cause sticking of the

electrode and result in poor quality welds.

Electrode Angle

The angle that the electrode makes with the work is important to ensure a

smooth, even transfer of metal. When welding in down hand, fillet, horizontal

or overhead the angle of the electrode is generally between 5 and 15 degrees

towards the direction of travel. When vertical up welding the angle of the

electrode should be between 70 and 80 degrees to the work piece.

Travel Speed

The electrode should be moved along in the direction of the joint being welded

at a speed that will give the size of run required. At the same time, the electrode

is fed downwards to keep the correct arc length at all times. Excessive travel

speeds lead to poor fusion and lack of penetration. While too slow a rate of

travel will frequently lead to arc instability, slag inclusions and poor mechanical

properties.

Electricity

The electricity flows through the electrode cable to the attached electrode. The

electricity will not leave the electrode unless it touches an earthed object.

Electricity always finds the fastest path to the earth. When the earth cable clamp

is connected to the metal work piece a direct earth connection is created back to

the welder. When the electrode makes contact with the earthed work piece an arc

is created. The electricity flows through the electrode, the metal work piece and

then through the earth cable straight back to the welder.

Earth Clamp

Prior to connecting the earth clamp it may be necessary to clean the surface of

the work piece using the metal brush. Attach the earth clamp firmly to the work

piece ensuring there is good metal to metal contact. Clamp it where it will not be

in the way. This clamp provides an earth connection back to the welder. Always

ensure the welder is disconnected from the power supply before attaching

electrodes into the holder.

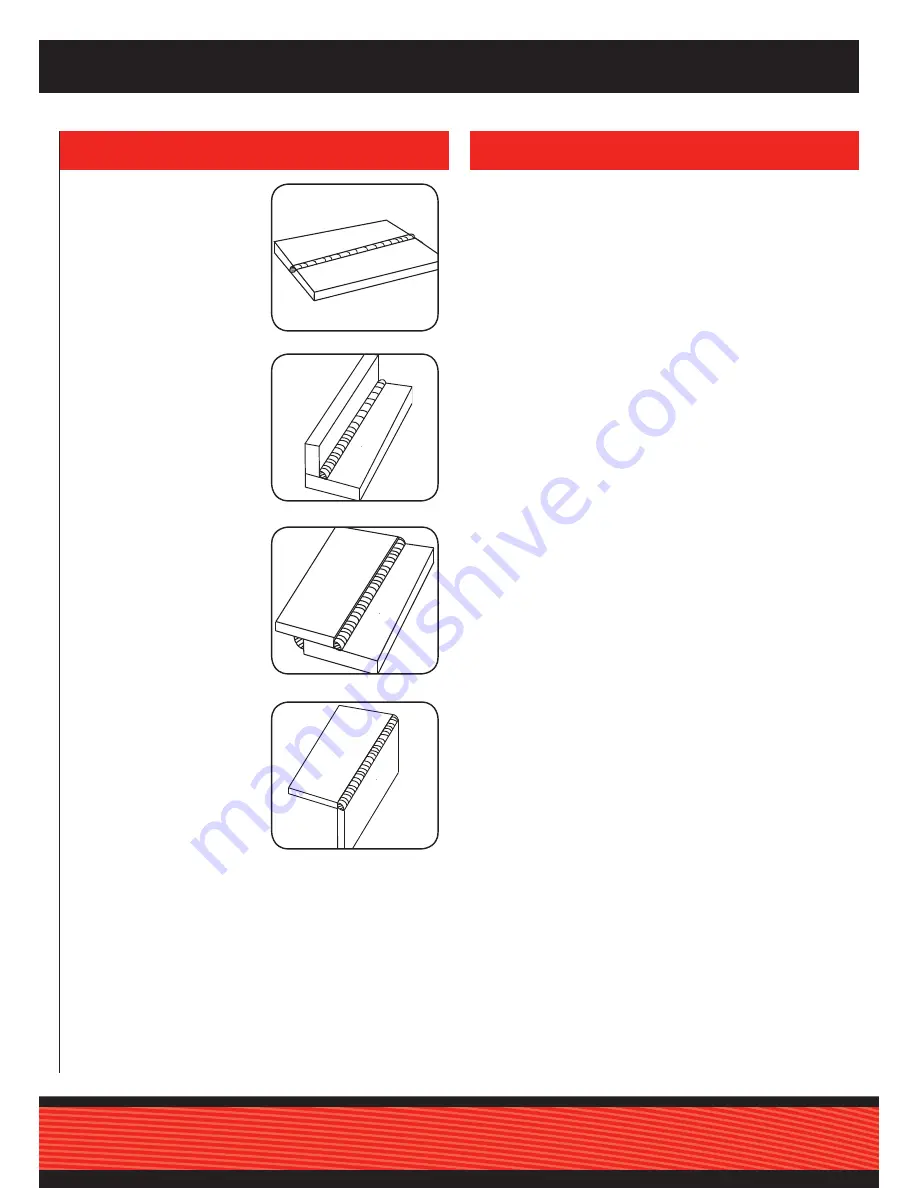

Butt Joint

Is the joining of two pieces of

material together along a single

edge in a single plane. Two sheets

of metal are laid side-by-side and

joined together along a single joint.

Fillet Joint

Is a type of joint used for weld-

ing pieces or plates in which the

angle between them varies from

0

°

to 180

°

. The edge of one plate

is brought against the surface of

another not in the same plane. The

joint can be welded on one or both

sides.

Lap Joint

The edges of a plate are lapped

one over the other and the edge of

one is welded to the surface of the

other.

Corner Joint

A corner joint consists of two pieces

of material joined at their edges to

form an “L” shape.

ARC WELDING

Electrodes

Always store the electrodes in a dry place protecting them from moisture. Should

electrodes become damp or moist, bake them in an oven at 200 - 250˚C for 2

hours. Unless the electrodes are vacuum packed, basic coated electrodes will

always require such baking prior to use.

Metal arc welding electrodes consist of a core wire surrounded by a flux coating.

The flux coating is applied to the core wire by an extrusion process.

The coating on arc welding electrodes has a number of purposes:

•

To provide a gaseous shield for the weld metal, and preserve it from

contamination by the atmosphere whilst in a mol ten state.

•

To give a steady arc by having ‘arc stabilisers’ present, which provide a bridge

for current to flow across.

•

To remove oxygen from the weld metal with ‘deoxidised’.

•

To provide a cleansing action on the work piece and a protective slag cover

over the weld metal to prevent the formation of oxides while the metal is

solidifying. The slag also helps to produce a bead of the desired contour.

•

To introduce alloys into the weld deposits in special type electrodes.