OSAKA OPERATING INSTRUCTIONS –COC 30- Page

8

These commands have a bistable function, which means that

at the first command the AUX output is activated whereas on

the second it is deactivated.

In this mode, the AUX output can also be switched off

automatically after a certain time that can be set under the “

AO

t” parameter.

With "AOt" = 0 the output is only activated and deactivated

manually, using the DOWN/AUX key or the digital input.

= 5 – mutable alarm: the AUX output is activated together with

the buzzer when alarm conditions exist and, like the buzzer, it

can be muted by pressing any key.

= 6 – non-mutable alarm: the AUX output is activated when

alarm conditions exist and remains activated for as long as

such conditions persist.

4.8 – DIGITAL INPUTS

The instrument has three settable digital inputs for free voltage

contacts.

All the digital input setting parameters are contained in the

“

]

In”

group.

The function logic of the digital inputs is established by the

parameters

“i1L”, “i2L”, “i3L”

, which can be programmed as

follows:

= On – contact normally open: the programmed function occurs

on the closure of the contact connected to the input.

= OFF – contact normally closed: the programmed function

occurs on the opening of the contact connected to the digital

input.

The action of the digital inputs can be delayed using the

following parameters:

“i1d”, “i2d”, “i3d”

, which can be programmed in seconds.

With regards to operation, the digital input acts according to

the

"i1F", “i2F”, and “i3F”

parameters, which can be

programmed as:

= 0 – not operative

= 1 – external alarm signal: on input intervention, the alarm is

activated and the upper display alternately shows

"ALn"

(where n is the number of the digital input) and the temperature

measured.

= 2 – Remote control of auxiliary output AUX: the digital input

is used to command the auxiliary output AUX as described in

operation mode "AOF" = 4 of the auxiliary output

= 3 – Steam injection remote control: the digital input operates

as the instrument’s INJ key.

= 4 – Steam injection block: the intervention of the digital input

causes steam injection blockage. The function can be useful if

the instrument does not have the steamer probe and one

wishes to block injection by means of a steamer thermostat.

= 5 – Pulse command for switching on the extractor output for

multiple command. This can be used to facilitate the command

of the single extractor when more than one appliance is fitted

to an oven. If one desires to command a single extractor from

a number of instruments, it is possible to do so by

programming the former with “ECn”=OFF and all the others

with “ECn” =On, connecting the EXTR relay output of the

former in such a way that it commands the extractor,

connecting the EXTR relay outputs of all the others in parallel

and therefore at the digital input of the former, which will have

suitably programmed the digital input with this operation mode.

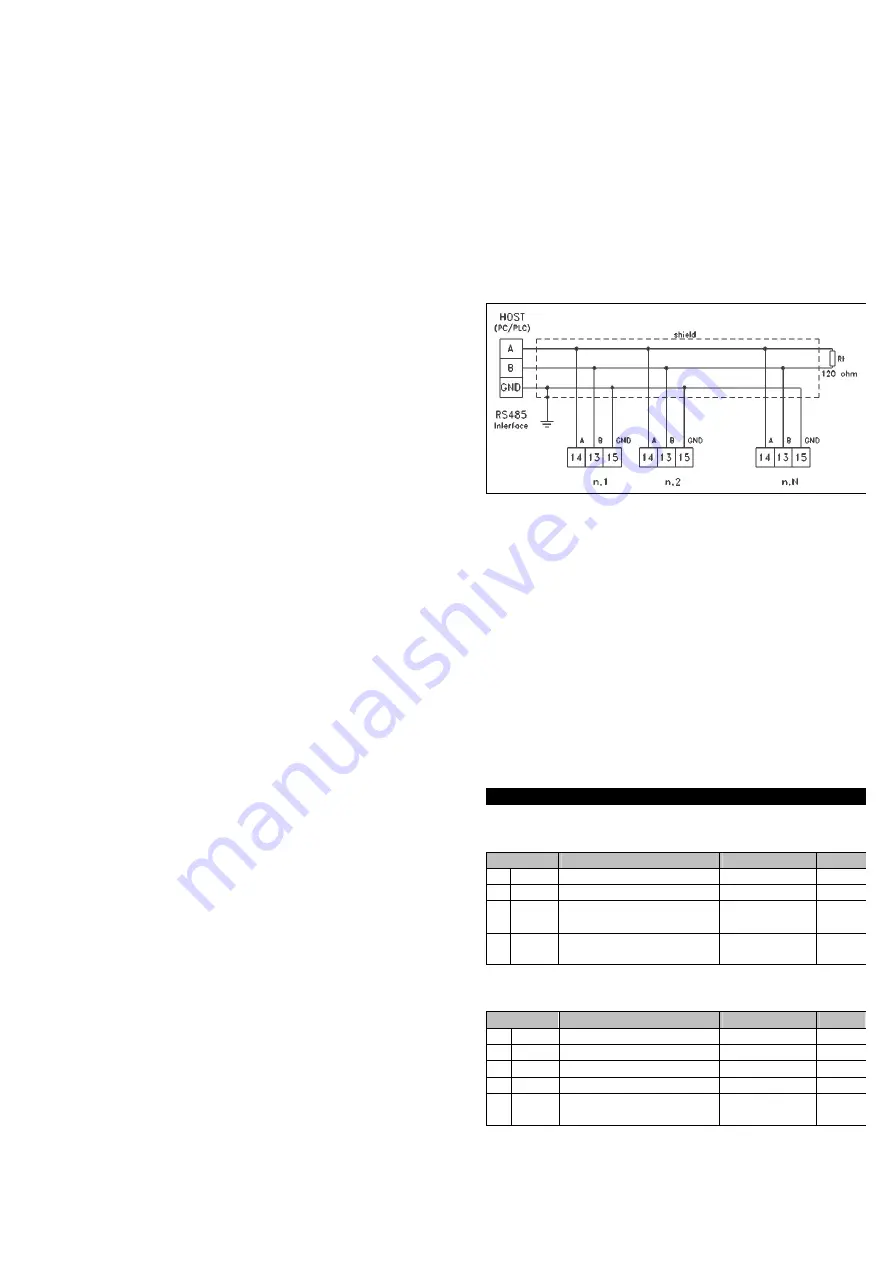

4.9 - RS 485 SERIAL INTERFACE

The instrument can be equipped with a RS 485 serial

communication interface, by means of which it is possible to

connect the regulator with a net to which other instruments

(regulators of PLC) are connected, all depending typically on a

personal computer used as plant supervisor. Using a personal

computer it is possible to acquire all the function information

and to program all the instrument’s configuration parameters.

The software protocol adopted for COC is a MODBUS RTU

type, widely used in several PLC and supervision programs

available on the market (COC series protocol manual is

available on request).

The interface circuit allows the connection of up to 32

instruments on the same line.

To maintain the line in rest conditions a 120 Ohm resistance

(Rt) must be connected to the end of the line.

The instrument is equipped with two terminals called A and B

which have to be connected with all the namesake terminals of

the net.

For the wiring operation they must be interlaced with a double

cable (telephonic type) and all the GND terminals must be

connected to the ground.

Nevertheless, particularly when the net results very long or

noised and being present potential differences between the

GND terminals, it is advisable to adopt a screened cable wired

as in the drawing.

if the instrument is equipped with a serial interface, the

parameters to be programmed are the following, all present in

the parameters group

“

]

SE”

:

"Add"

: Address of the station. Set a different number for each

station, from 1 to 255.

"bau"

: Transmission speed (baud-rate), programmable from

2400 to 38400 baud. 1 =2400 baud, 2 =4800 baud, 3 =9600

baud, 4= 19200 baud , 5 =38400 baud. All the stations have to

have the same transmission speed.

"PAC"

: Programming access. If programmed as "LoC" this

means that the instrument is only programmable from the

keyboard, if programmed as "Lor" it is programmable both from

the keyboards and serial line.

If an attempt is made to enter the programming from the

keyboard whilst a communication through the serial port is in

progress the instrument will visualise

"bSy"

to indicate the

busy state.

5 – PROGRAMMABLE PARÁMETER S

5.1 - PARAMETERS TABLE

“

]

SP” Group

(Set Point parameters)

Par.

Description

Range

Def.

1

SP1

TOP Set Point

SPL ÷ SPH

0

2

SP2

FLOOR Set Point

SPL ÷ SPH

0

3

SPL

(com)

Minimum Set Point

-99 ÷ SPH

0

4

SPH

(com)

Maximum Set Point

SPL ÷ 999

999

“

]

rG” Group

(temperature regulation and power control

parameters)

Par.

Description

Range

Def.

5

OP1

TOP power

0 ÷ 100 %

50

6

OP2

FLOOR power

0 ÷ 100 %

50

7

tCP

Power control Cycle time

1 ÷ 999 seg.

30

8

PSP

Power setting mode

1 - 2 – 3

1

9

HS1

Regulator differential 1

(TOP)

1 ÷ 999

2