Electrical Connections & Wiring

(Refer fig 1.2)

Wiring is to be carried out only when the switch is mounted and voltage free.

(a) Remove the top cover by unscrewing the black screw.

(b) Pass the cable through the cable gland and connect the wiring.

(c) Basically there are two connection as shown in the figure 1.2 one for

Line and another for Motor. Each has three wires for three phase. Please

ensure appropriate connection of phase wires. Two earthing screws are

provided to connect earthing wires from line and motor.

Certificate No.:

FM 72815

Kaustubha Udyog

7, Parichaya Society, 1000/6D, Navi Peth, Pune 411 030 INDIA

Tel. : +91-(0) 20 - 24332124 / 24321053

Fax : +91-(0) 20 - 25460486 / 24332124

Email : [email protected]

Website : http://www.orion-instruments.com

BULLETIN NO. : KA041220

AN ISO9001:2000 COMPANY

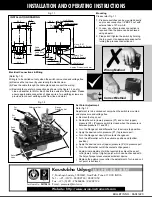

Mounting

Please refer Fig. 1.1

1. Pressure switches can be mounted directly

on process connection 1/2”BSP F nut with

external size of 27 mm A/F.

2. In case, any other process connection is

required then the same can be achieved

using adaptor.

3. Please don't tighten the switch by holding

the top cover. Use appropriate spanner for

turning the process connection nut.

Set Point Adjustment:

Refer fig 1.2

Adjustment is to be carried out only when the switch is mounted,

under pressure and voltage free

a. Remove the top cover.

b. Decide the cut-in (lower) pressure (P1) and cut-out (upper)

pressure (P2). (Pressure switch is closed when the pressure is

between pressure P1 and P2.)

c. Turn the Range nut and differential nut to extreme top position.

d. Apply the desired cut-in pressure (P1) to pressure port.

e. Turn the Range nut slowly till contacts changeover.

f. Turn the differential nut to the extreme positive end (bottom

position)

g. Apply the desired cut-out (upper) pressure (P2) to pressure port.

h. Turn the differential nut till the contacts changeover.

i. Some minor adjustment will be required to achieve the exact

cutin (lower) / output (higher) point, which can be checked with

the help of proper pressure measurement device.

j. Replace the polymer cover after the adjustment of cut-in and cut-

out point is achieved.

Fig. 1.2

Differential Nut

For

Motor

For

Line

Earth

Screw

Relief

Valve

104

1

0

0

60

Range

Operating Nut

60.0

4.5

7.0

7

0

.0

1

1

9

.0

3

7

.5

38.0

63.4

44.8

28.0

On

Off

Screw for Cover

On/Off Knob

Cable

Gland

Cable Entry

Screw

Hex. A/F 27

(for Fitting the Switch)

13.0

40.0

61.0

103.5

Pressure Port

1/2" BSP Female

Pr. Relief Valve

INSTALLATION DRAWING

Approx. Dimensions in mm

Fig. 1.1

27

mm

Wrong Method

Correct Method

INSTALLATION AND OPERATING INSTRUCTIONS