24

Protective function

10 Protective function

The driver provides alarms that are designed to protect the driver from overheating, poor connection, misoperation,

etc. (protective functions), as well as warnings that are output before the corresponding alarms are generated (warning

functions). Before resetting an alarm, always remove the cause of the alarm and ensure safety.

Refer to the USER MANUAL for how to reset an alarm.

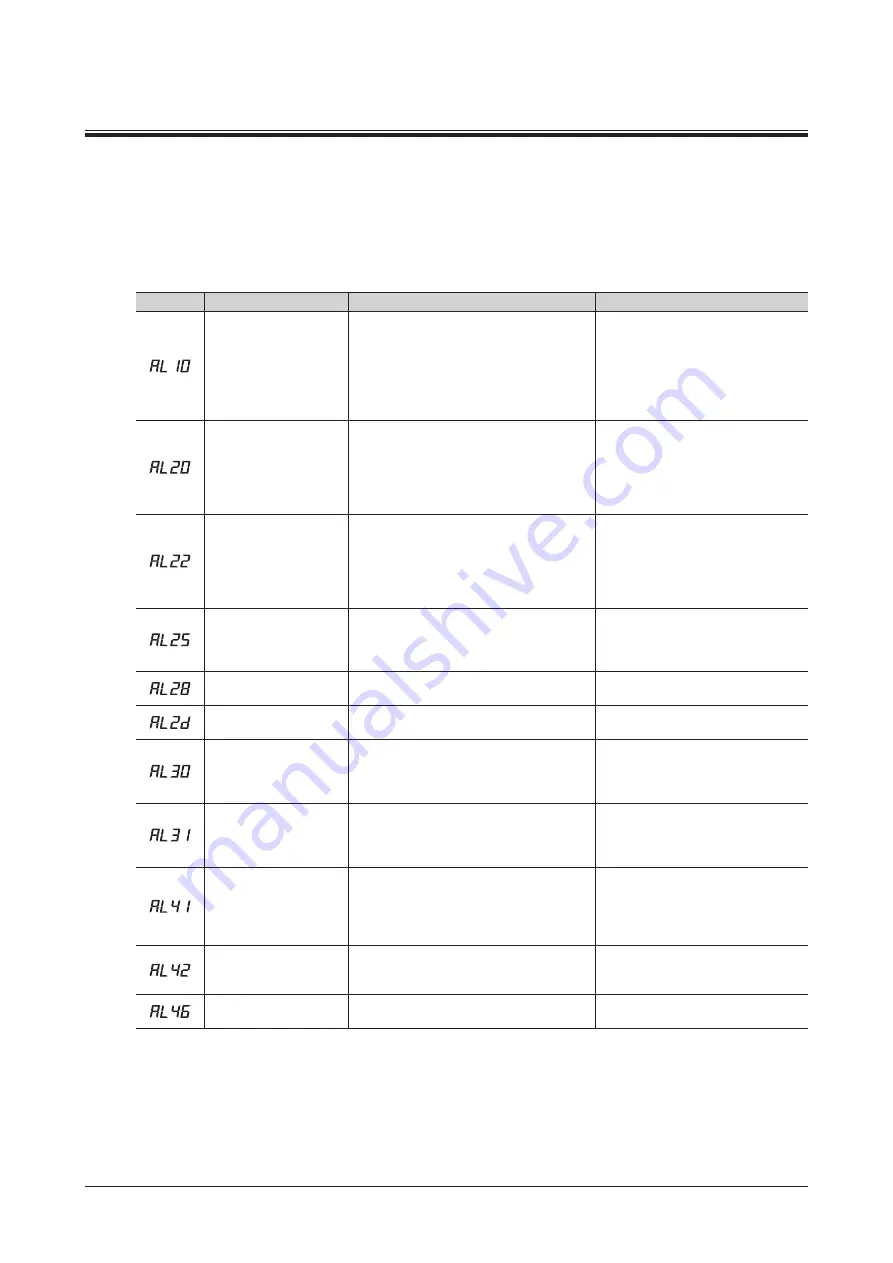

10.1 Alarm list

Alarm code

Alarm type

Cause

Remedial action

Excessive position

deviation

•

When the motor was in an excitation state,

the deviation between the command position

and actual position at the motor output

shaft exceeded the value set in the “Excessive

position deviation alarm" parameter.

•

A load is large or the acceleration/deceleration

time is too short.

•

Decrease the load.

•

Reconsider the operating conditions

such as the acceleration/deceleration

time.

Overcurrent

Excessive current was flown through the driver

due to ground fault, etc.

•

Check whether the wiring between the

driver and motor is damaged.

•

If the alarm cannot be cleared even

when the power has been cycled,

contact your nearest Oriental Motor

sales office.

Overvoltage

•

The power supply voltage exceeded

approximately 120% of the rated voltage.

•

A load exceeding the allowable gravitational

capacity of the motor was driven or sudden

starting/stopping of a large inertia was

performed.

•

Check the voltage of the main power

supply.

•

If the alarm is generated during

operation, decrease a load or increase

the acceleration/deceleration time.

•

Connect the regeneration resistor.

Undervoltage

The power supply voltage dropped below

approximately 60% of the rated voltage.

•

Check the voltage of the main power

supply.

•

Check the wiring of the power supply

cable.

Sensor error

The encoder line of the motor was disconnected.

Or the encoder connector was come off.

Check the connection between the driver

and the motor.

Main circuit output error

∗1

The power line of the motor was disconnected.

Or the motor power connector was come off.

Check the connection between the driver

and the motor.

Overload

•

A load exceeding the rated torque was applied

to the motor for five seconds or more.

•

The motor was started in a state where the

motor temperature was low.

•

Decrease the load.

•

Reconsider the operating conditions

such as the acceleration/deceleration

time.

Overspeed

The rotation speed of the motor output shaft

exceeded approximately 5200 r/min.

•

Decrease the load.

•

Reconsider the operating conditions

such as the acceleration/deceleration

time.

EEPROM error

•

Stored data was damaged.

•

Data became no longer writable or readable.

•

Initialize all parameters.

•

If the alarm cannot be cleared even

when the power has been cycled,

contact your nearest Oriental Motor

sales office.

Initial sensor error

The encoder line of the motor was disconnected

before the main power supply was turned on.

Or the encoder connector was come off.

Check the connection between the driver

and the motor.

Alarm initial drive

∗2

The main power supply was turned on when

the operation input signal was being ON.

Turn the operation input signal OFF.

∗1

This alarm is not generated when the torque limiting value is set to less than 250%.

∗2

This alarm is generated when the “Alarm initial drive” function was set to enable.

Summary of Contents for BX2 Driver Edition Series

Page 7: ...7 Precautions for use...

Page 13: ...13 Installation...