28

Correct tensioning is of special importance for the reliable and

efficient transmission of power. Proper tensioning of the stationary

belt will ensure that it will run at the correct tension.

●

Insufficient tension coupled to high drive loads will lead to the

belt jumping teeth on the pulley and ultimately to belt breakage.

●

Excessive tension under similar conditions will cause severe

wear, shearing of the belt teeth, excessive running noise and

bearing damage.

It is advisable therefore to calculate and set the static tension for

each drive individually using the formulae below. The tensioning

factor c

v

takes account of the loads combined in the overall service

factor c

2

.

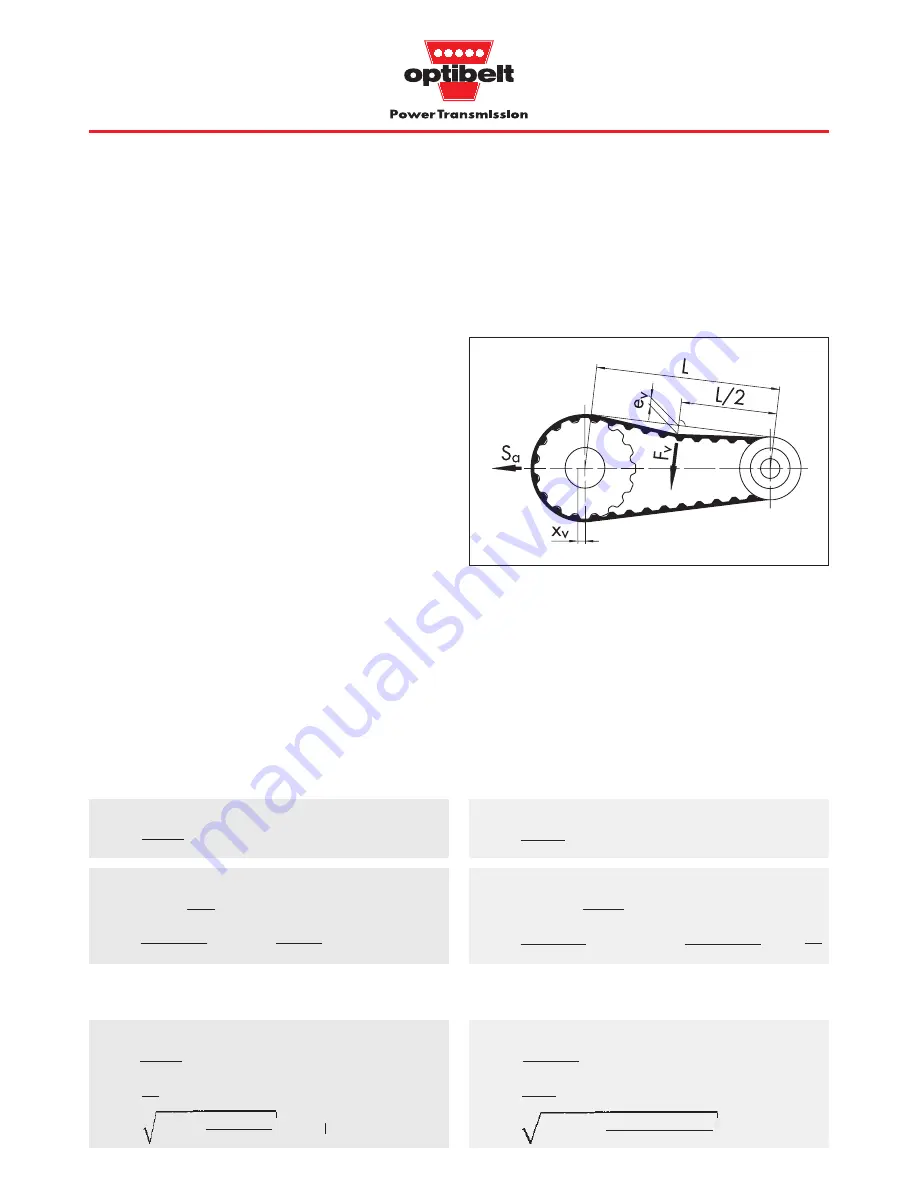

Setting the static tension

One pulley only of the drive may be fixed when the static tension

is adjusted. The second pulley and the other pulleys of a multiple

pulley drive must be able to rotate freely.

The test force F

v

should be applied in the centre of the span length

‘L’ perpendicular to it. Sharp-edged objects MUST not be used for

depressing the timing belt to avoid belt kink. Correct static tension

is achieved when the deflection e

v

corresponds to the calculated

value.

When the drive system has more than the two pulleys shown in

Figure 3.1 the tension can be measured between any two pulleys

in the system provided the belt is in contact with these pulleys with

the same face (top or bottom). The only difference will be e

v

which

will change as a function of span length.

3.5 ZRM/ZRP tensioning

Calculation and setting of tension for

optibelt

ZRM/ZRP

timing belt drives

Alternatively, the belt can be tensioned statically using the calcu-

lated static shaft load S

a

.

By virtue of the zero stretch tension cord, the belt will require no

further tension checks after fitting.

Tensioning

Test force F

v

and deflection e

v

for span length L

F

v

=

c

v

and S

n3

see above

e

v

=

L = a

nom

for i

U

1

L

=

a

nom2

–

for i

U

1

F

v

=

= 54 N

e

v

=

= 8.0 mm

L

=

408.71

2

–

= 401.05 mm

L

50

(d

wg

– d

wk

)

2

2

1.3 · 828

20

401.1

50

(190.98 – 79.58)

2

2

Static shaft load S

a

and centrifugal force S

n3

S

a

= c

v

· S

n3

L see below

S

n3

=

v

eff

=

formulae page 13

L

a

nom

S

a

= 1.3 · 828

= 1056 N

S

n3

=

= 828 N v

eff

=

= 6.04

5.0 · 1000

6.04

401.05

408.71

Tension factor and forces

Tension factor c

v

c

v

=

+ 0.9

1.05

≤

c

v

c

v

=

+ 0.9 = 1.3

1.8 – 1

2

Formulae

Example

(using the values from page 27)

79.58 · 1450

19100

m

s

For formula symbols, see also page 14

F

v

= load to set tension

(N)

S

n3

= centrifugal force

(N)

e

v

= span deflection under load F

v

(mm)

L

= span length

(mm)

d

w1

· n

1

19100

P

Ab

· 1000

v

eff

c

2

– 1

2

c

v

· S

n3

20

Figure 3.1: Adjusting belt tension

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Summary of Contents for ZRL

Page 54: ...53 ...

Page 95: ...94 ZRM ZRP Data Sheet Notes ...