3

E106887#2

Instructions

6b

6c

6d

6e

6f

6a

7b

7a

10a

10b

10c

8a

9a

8b

9b

8c

9c

7d

7c

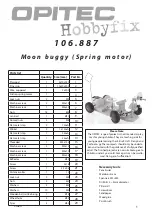

6. Axle fixing

Measure and mark a line 1mm past the first hole , left and right (in a 7 hole length of metal strip ) ( Use a felt tip pen )

Use a pair of pliers to bend the ends up at 90 degrees ( Photographs 6b-6c)

Note:

You can also bend the ends in a vice!

An der gegenüberliegenden Seite den Flachstab ebenso einspannen und abwinkeln (U-Form/6e-6f).

Note:

Ensure both ends are bent in the same direction!

7. Fitting the axle to the chassis

See photo 7a – Screw a lock nut ( Part 23 ) on the M4 x 10 ( Part 16 ) and then remove it

Now add a washer (26) and then insert the machine screw through from underneath through the second hole

from the front in the plywood chassis ( Photograph 7b)

Place the axle holder on top so that it is central and then add the lock nut ( Plastic ring faces down ) so the axle

holder can move without play.

Note:

Mounting the lock nut ( 7d)!

8. The front axle

Measure and saw the threaded axle rod M4 x 150mm ( Part 15 ) to 115mm long.

File the sawn end to remove any burr.

10. Screw a M4 domed ( Part 10) nut on the threaded axle ( Photograph 10a )

Slide the threaded rod in the metal axle holder then screw on the next pair of lock nuts (8) ( After the end of the

axle ) the finally finish with a domed nut.

9. Mounting the wheels

Assemble the wheels centres (28 ) and tyres ( 29) ( 9a +9B )

Slide a wheel on each axle of the friction motor