Managing Operators and Jobs

73

Model 72™ Operator Manual

OPEX Corporation

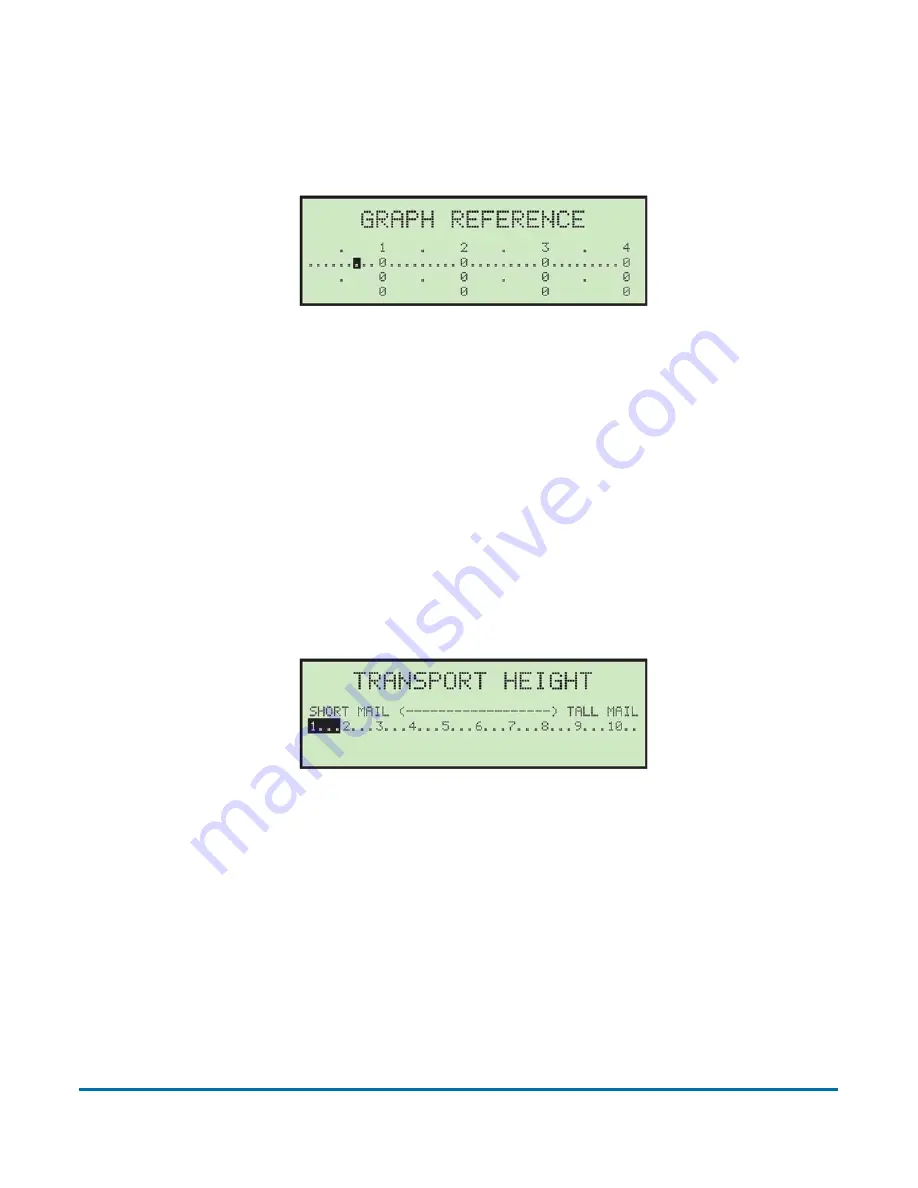

5.4.6. GRAPH REFERENCE

During run mode, a graph is displayed that shows an operator's performance

(Figure 5-31).

Figure 5-31: Graph Reference screen

A horizontal line, representing the average or target rate is also displayed. The

graph shows counts of 1000, 2000, 3000 and 4000 envelopes. Each 100

increment between is represented by a dot. The target rate can be set by

moving the cursor with the right and left arrows and pressing

Enter

. Values

may be changed in increments of 100. Figure 5-31 shows a target rate of 700

per hour. Press

Cancel

to exit this screen.

5.4.7. TRANSPORT HEIGHT

This job parameter is used to set the main transport height (Figure 5-32).

Figure 5-32: Transport Height screen

Transport height can be set on a scale from 1 (short mail) to 10 (tall mail). The

transport height can be adjusted by moving the cursor with the right and left

arrows and pressing

Enter

.

The Transport Height scale from 1-10 corresponds to 0.2875” (7.3025 mm)

increments from 3.5” (88.9 mm) to 6.375” (161.925 mm).

•

Mathematically in inches: (6.375-3.5)/10= 0.2875

•

Mathematically in millimeters: (161.925-88.9)/10= 7.3025

Summary of Contents for Model 72

Page 14: ...14 Introduction Model 72 Operator Manual OPEX Corporation This page is intentionally blank...

Page 36: ...36 Overview Model 72 Operator Manual OPEX Corporation This page is intentionally blank...

Page 54: ...54 Operation Model 72 Operator Manual OPEX Corporation This page is intentionally blank...

Page 92: ...92 Maintenance Model 72 Operator Manual OPEX Corporation This page is intentionally blank...

Page 93: ...Model 72 Operator Manual 7 Troubleshooting 7 1 Sensors 94 7 2 Error messages 95...

Page 104: ...OPEX Corporation 305 Commerce Drive Moorestown NJ 08057 4234 USA http www opex com...