DX26/DX32 OPERATOR MANUAL

24

Rev 4 –11/4/2021

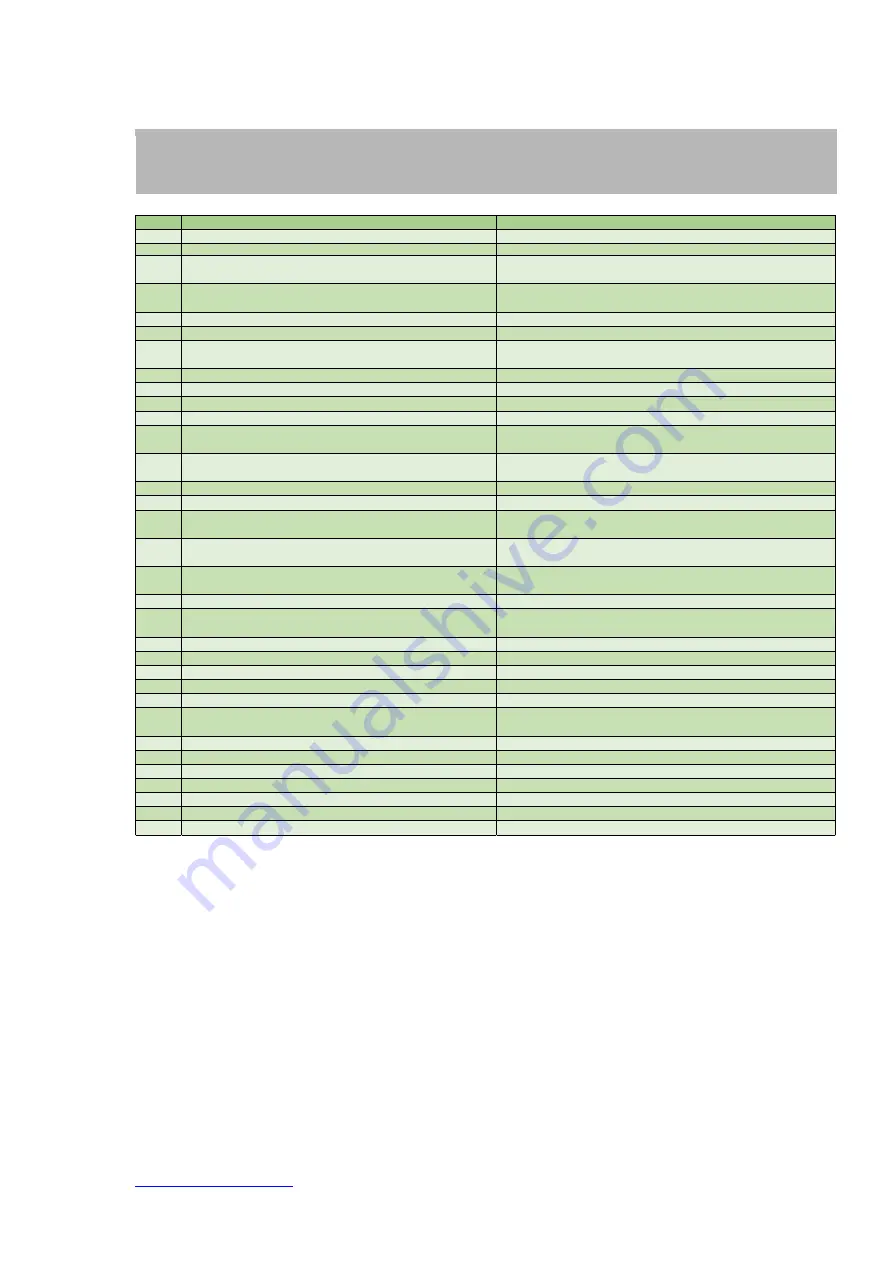

Controller Error Code Table

Code

Failure Description

Cause and Solution

1

Lower feedback speed

The controller is faulty, please contact the manufacturer

2

Kernel running error

The controller is faulty, please contact the manufacturer

3

The controller and the motor are overloaded for a long time

Check whether the controller matches the motor, and whether the controller

is too small

5

The position after the electronic gear ration exceed the max. motor

speed

The controller is faulty, please contact the manufacturer

6

In speed model, the speed command exceeds max. speed of motor

The controller is faulty, please contact the manufacturer

7

In torque model, the torque command exceeds max. torque of motor

The controller is faulty, please contact the manufacturer

11

Motor 2 minutes max. current protection

The motor is blocked; check whether the brake is opened and wheter there is

any foreign matter stuck in the drive mechanism

12

Controller overcurrent

Controller selection error, or controller failure, contact the manufacturer.

13

Bus capacitor charging failure

The controller is faulty, please contact the manufacturer

14

Main contactor connection failure

Check whether the main contractor is connected properly

15

Electromagnetic brake connection failure

Check whether the electromagnetic brake is connected properly

16

The battery voltage is severely low

Check the battery power, or the controller battery voltage level is set

incorrectly

17

Battery voltage is too high

Check the battery voltage, or the controller battery voltage level setting is

wrong.

18

Power board is severely overheated

The controller is protected and temporarily suspended.

19

The motor is severely overheated

The controller is protected and temporarily suspended.

20/R20 Accelerator problem

Check whether the accelerator cable is loose and whetehr the accelerator is

burned out.

21

Main contactor contact welding

Check whether the main contractor is damaged or not, replace the main

contactor.

22

5V output failure

Motor encoder is hort-circuited, or other external 5V devices are short-

circuited, or the controller is faulty, contact the manufacturer.

23

MACID test failure

The setting of the controller CAN network ID number is repeated, reset it.

24

Main contactor drive failure

Check whether the main contractor is damaged and replace the main

contactor

25

Power model failure

The controller is faulty, contact the manufacturer.

31

Battery voltage is low

The battery is low, charge it as soon as possible.

32

Power board is slightly over-temperature

Reduce load

33

Power board low temperature

The ambient temperature is too low.

34

Motor slightly over temperature

Reduce load

35

12V overput failure

The power supply of the handheld terminal is short-circuited; or the controller

is faulty, contact the manufacturer.

36

Drive3 connection failure

Check Drive3 connection.

37

Drive4 connection failure

Check Drive4 connection.

38

EEPROM read and write parameter error

The controller is faulty, please contact the manufacturer

39

Parameter overrun error

Parameter setting failure, contact the manufacturer.

40

Opertion timing error

Reset, and follow the correct sequence.

41

Remaining battery power 20%, alarming

Charge the battery

42

Remaining battery power 15%, alarming

Charge the battery