4-7

Always use flexible tubing between en-

gine and the fuel supply to avoid line failure due to

vibration.

Never use galvanized or copper fuel

lines, fittings or fuel tanks with diesel fuel systems.

Condensation in the tank and lines combines with

the sulfur in diesel fuel to produce sulfuric acid. The

molecular structure of the copper or galvanized lines

or tanks reacts with the acid and contaminates the

fuel.

Carefully clean all fuel system components before put-

ting the set into operation. Any dirt or contamination may

cause major damage to the fuel injection system.

Dirt in the system can severely damage

both the injection pump and the injection nozzles.

Dirty fuel is one of the major causes of engine failure.

Even a tiny particle of dirt in the injection system may

stop the engine. Because diesel injection systems

have extremely precise tolerances, make certain that

fuel is kept clean.

Separate Fuel Tanks

The fuel tank top must be lower than the fuel pump level

to prevent putting a static head on the fuel pump inlet. If

the fuel tank is shared with another engine, use separate

fuel lines for both engines to avoid starving either one.

The following restrictions apply to separate fuel tank in-

stallation:

1. The bottom of the fuel tank must not be more than 6

feet (1.8 m) below the fuel transfer pump inlet, un-

less an auxiliary electric fuel pump is added. The

maximum lift capacity of the transfer pump is six

feet. See the Wiring Diagram for the connection.

2. If the tank is installed above the fuel pump inlet level

without a supply line shutoff valve, a ruptured pump

diaphragm could cause oil dilution, fuel loss, and

fuel leakage to the crankcase.

3. If the maximum fuel lift must be exceeded on any in-

stallation, consult Onan Application Manual T-030

for information on installing a day tank and an elec-

tric solenoid shutoff valve.

4. Use an electric or manual shutoff valve if the mini-

mum fuel level in the tank is higher than the pump

inlet, to provide positive fuel shutoff when the en-

gine is stopped. This valve also prevents loss of fuel

from possible leaks between the tank and the fuel

pump.

Fuel leaks create the hazard of explo-

sion and fire, which can cause severe personal in-

jury or death. For these reasons, always use flexible

tubing between the engine and the fuel supply, to

avoid leaks due to vibration and/or fuel line failure.

Make certain that the fuel system and the fuel tank lo-

cation meet applicable local codes.

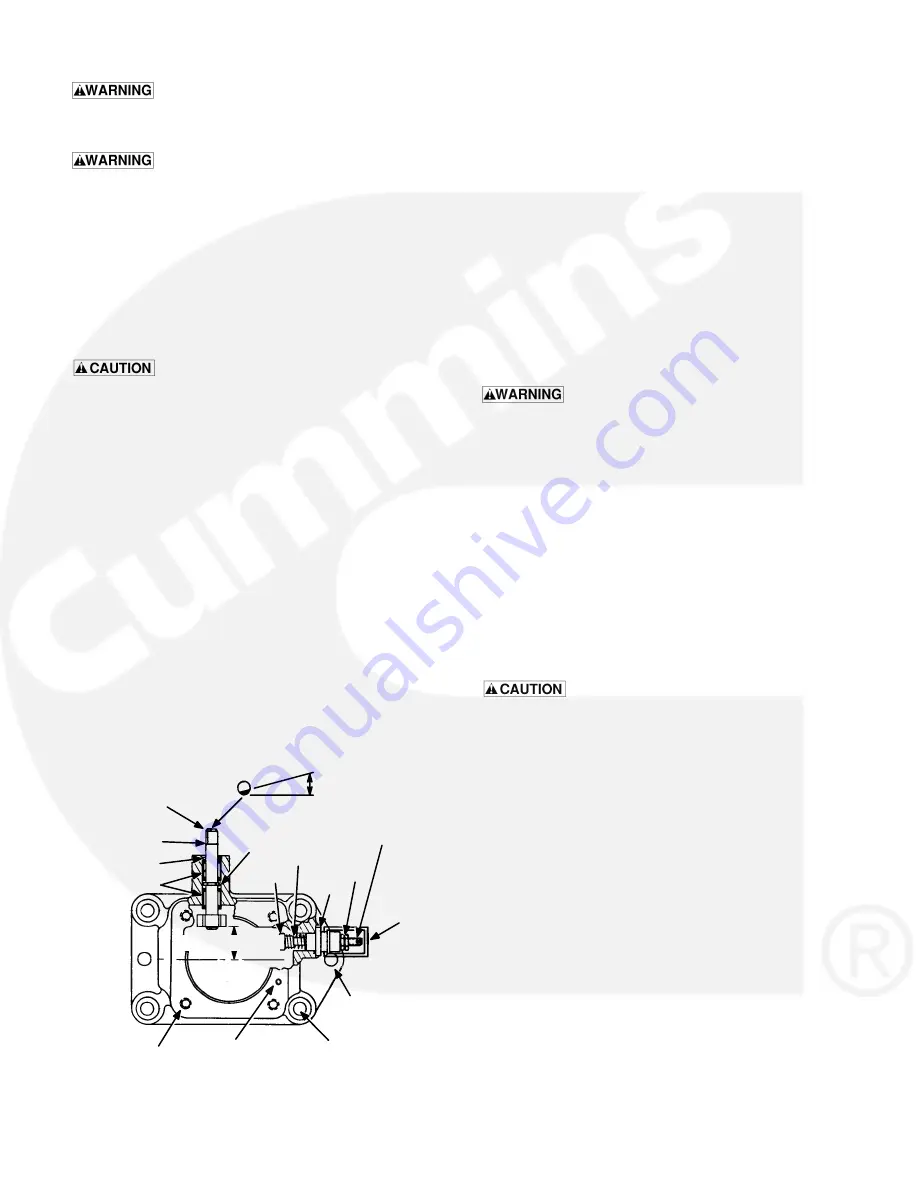

INJECTION PUMP ADAPTER ASSEMBLY

(DJE only)

A spring and plunger assembly on the side of the pump

adapter (Figure 4-7) on the DJE generator set limits the

maximum power output of the engine for safe operation

and permits maximum fueling during starting.

Do not change the adjustment of this de-

vice unless absolutely required. The warranty may

be voided if the fuel stop is intentionally altered to in-

crease engine power.

15 DEGREES

SPRING

LOCK

NUT

FS1852C

FIGURE 4-7. INJECTION PUMP ADAPTER ASSEMBLY

TOP END

SHAFT POSITION

OF FLAT FOR

INSTALLING PUMP

TO ADAPTER

SHAFT

AND YOKE

ASSEMBLY

SEAL

BEARINGS

OVERLOAD FUEL PLUNGER

ADJUSTED AT FACTORY -

DO NOT CHANGE

GUIDE

PLUNGER

DUST

COVER

ADAPTER

DOWEL PIN

HOLES (2)

ADAPTER MOUNTING

BOLT HOLES (4)

DOWEL PIN HOLE

(BRYCE ONLY)

PUMP MOUNTING

HOLES (4)

EXTERNAL

RETAINING

RING

1 INCH (25.4 MM)