・

Head ×1

・

Wrench ×1

・

Hose elbow ×1 (E9NC-TH

□

L

□

)

・

Clamp spanner, Pin, Tightening nut, Wave washer ×1 each (E9NC-TH

□□

F)

・

Manual (this paper) ×1 each

(

Japanese, English, Chinese

)

Checking the package contents

5. Specifications

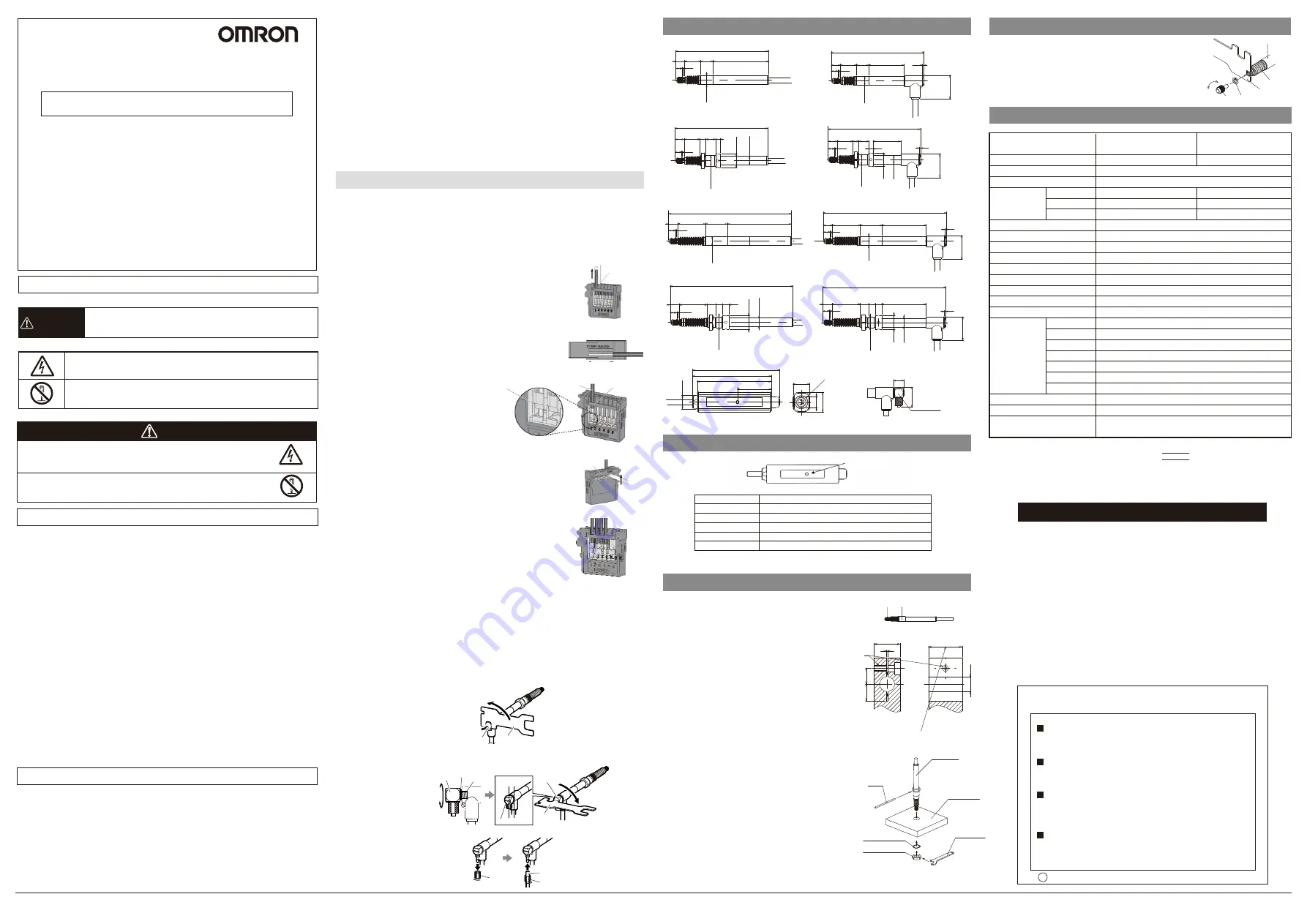

1. Dimensions

2

.

Display of preamplifier block

3. Installing Heads

E9NC-TH

□□

Series

・

The suction air must be dry air with a negative pressure of 0.04 to 0.067 MPa.

・

The outside diameter of the tube for air suction inlet must be 4 mm.

・

Air suction draws the spindle in.

・

If the spindle extrusion rate is high, the amplifier indication may display an error when

a workpiece is contacted.

・

Too much impact may shift the ball retainer inside the bearing, resulting in less

operating range. If so, adjust the spindle rate.

■

Using air supply

(E9NC-TH5L/E9NC-TH5LF/E9NC-TH12L/E9NC-TH12LF)

■

Installation

Model

Measuring range(Moving range)

Resolution

Precision (at 20 °

C)

Measuring force

(at 20 °C)

Ambient temperature

Ambient humidity

Maximum response speed

Origin detection speed

Origin position

Degree of protection

Vibration resistance

Shock resistance

Number of sliding

Material

Weight (packed state/main unit only)

Probe

Accessories

Head

Probe

Rubber boot

Cable

Preamplifier

Tightening nut

Wave washer

Set upward

Set horizontal

Set downward

E9NC-TH5S/E9NC-TH5SF

E9NC-TH5L/E9NC-TH5LF

5mm

0.1μm

1μm

0.35±0.25N

0.4±0.25N

0.45±0.25N

Operating: -10 to 55°C, storage: -20 to 60°C (with no icing or condensation)

Operating and storage: 35% to 85% (with no condensation)

80m/min

80m/min

1±0.5 mm from the lowest point of spindle extrusion position

Head: *1, Preamplifier: IEC IP40

100m/s

2

(20〜2000Hz) 20 min each in X, Y, and Z directions

1000m/s

2

3 times each in X, Y, and Z directions

92 million times (based on Omron's dedicated evaluation)

SUS303

Carbide

NBR

PVC

ABS

SUS410 (E9NC-TH□□F only)

SK5 (E9NC-TH□□F only)

Approx. 340g/approx. 110g

With spherical surface of carbide, thread size of M2.5

Instruction Sheet, Wrench, Hose elbow(E9NC-TH□L□)

Accessory for flanged model only(E9NC-TH□□F)*1

E9NC-TH12S/E9NC-TH12SF

E9NC-TH12L/E9NC-TH12LF

12mm

0.4±0.3N

0.5±0.3N

0.6±0.3N

4

.

Attaching the probe

・

Use the dedicated wrench that comes with the product for attaching

and detaching the probe. Do not apply torque of 0.1 N

・

m or more to

the spindle during the task. Otherwise damage may result.

・

Unless you use a flat probe, it is recommended to use the accessory

spring washer of nominal 2.5 or screw lock to prevent the probe to

loosen. (Reference tightening torque value: 0.05 to 0.06 N

・

m)

<Straight Model>

(

E9NC-TH5S/E9NC-TH5

L

/E9NC-TH12S/E9NC-TH12L

)

・

Mounting head, be sure to grab the stem.

・

To attach the head to other equipment, avoid securing it on a

position where a screw directly contacts this product.

・

As this product uses a ball bearing, tightening the stem too much

could damage the measurement axis, resulting in crippled

movement.

・

To attach it to equipment using a holder, use the <recommended

mounting jig> with specified tightening torque of 0.6 N

・

m to

secure.

・

Attach the stem so that the slotted block should be tightened by

the screw. Never attach the stem by cutting screw thread in the

Ø

8 mm hole and by screwing the stem with a setscrew. Or sliding

movement or precision may be degraded.

<Flanged Model>

(E9NC-TH5SF/E9NC-TH5LF/E9NC-TH12SF/E9NC-TH12LF)

・

Recommended diameter of the hole to attach the head is

Ø

9.7

±

0.15 mm.

・

The mounting plate thicknesses are shown below:

E9NC-TH5SF/E9NC-TH5LF: 9 to 11 mm

E9NC-TH12SF/E9NC-TH12LF: 7 to 11 mm

・

To attach the head, always use the accessory tightening nut,

wave washer, clamp spanner, and pin that come with the product.

The tightening torque shall be applied so that the wave washer

should be completely flat.

Recommended tightening torque: 1.0 N

・

m

Maximum tightening torque: 2.0 N

・

m

ATTENTION

・

To prevent cables to cut, fix it in a proper place. Avoid pulling

cables too strongly or bending them too much.

・

The degree of parallelization affects the precision of detection.

Use the mounting bracket (or sleeve) so that it should be kept

within 0.3 mm for 100 mm of movement.

・

Do not apply force to rotation direction after securing the stem.

Or it may be damaged.

Unit: mm

E9NC-TH12S

E9NC-TH12LF

E9NC-TH12SF

Cable length between head and

preamplifier: 2 m(φ4.8)

Attaching the hose elbow

E9NC-TH12L

E9NC-TH5S

E9NC-TH5L

E9NC-TH5SF

E9NC-TH5LF

Cap

Dedicated wrench

Dedicated

wrench

Hose elbow

Tighten to parallel

position

Hose elbow

M5 screw

Gasket

Hose elbow

Ø

4 mm tube

Securing ring

Securing ring

6

0.6

8.1 14.2

11

49.5

(82.8)

Ø

8

-

0 0.009

(82.7)

0.6

8.1 14.2

11

31.6

6

21

Ø

8

- 00.009

1.3

(82.8)

6

0.6

8.1 14.2 5.3 8.7 4

Ø

9.5

-

0 0.009

Ø

12

Ø

7.9

0.6

6

8.1 14.2 5.3 8.7

4

24.6

(82.7)

Ø

9.5

- 00.009

Ø

7.9

Ø

12

21

1.3

(109.7)

6

0.6

8.1

Ø

8

-

0 0.009

19.5

57.2

24.9

6

0.6

8.1

24.9

19.5

39.3

(109.6)

Ø

8

- 00.009

21

1.3

6

0.6

8.1

24.9

8 5.8

5.7

Ø

9.5

-

0 0.009

Ø

12

Ø

7.9

(109.7)

6

0.6

8.1

24.9

8 5.8 5.7

39.3

(109.6)

Ø

9.5

- 00.009

Ø

12

Ø

7.9

21

1.3

(9.2)

(17.5)

Hose elbow

LED Indication Status

Meanings

Off

Non-energized

Flashing blue

Energized, origin point not passed yet, or origin point detecting

Blue light ON

Energized, origin point detected (with origin point use setting ON)

Red light ON

Head speed error

Flashing red

Head circuit failure

+0.014 +0.005

Tightening Torque: 0.6 N・m

Material: SUS303

Unit: mm

1

14

8.5

9

M3

Ø

8

G6

Probe Stem

<Recommended Mounting Jig>

Head

Mounting Plate

Pin

Clamp spanner

Wave washer

Tightening nut

Stem

Spindle

Dedicated

wrench

(Spindle fixation)

Probe Washer

1. Remove the cap.

3. Attach

Ø

4 mm tube.

2. Attach the hose elbow.

Manually tighten the M5 screw until the gasket contacts the wall. Then use the

dedicated wrench to tighten by 90°.

*1. E9NC-TH□L□ When using the hose elbow

IEC IP67

E9NC-TH□L□ When not using the hose elbow

E9NC-TH□S□

*2. Clamp wrench, Pin, Tightening nut, Wave washer

Operation Indicator

Do not forcibly bend or pull the cables.

Do not put a heavy object on them or heat them.

Doing so may damage the cables, resulting in a fire.

Do not disassemble or alter the unit. There is a risk of

injury or electric shock. And it may cause damage on the

internal circuit.

●

Warning: Electric Shock

Indicates a risk of electric shock under certain conditions.

WARNING

●

Resolution prohibition

Indicates prohibition when there is a risk of minor injury from electrical

shock or other source if the product is disassembled.

©

OMRON Corporation 2013 All Rights Reserved.

INSTRUCTION SHEET

Model

E9NC-TH

□□

Series

Contact-Type Smart Head (Detection Type)

PRECAUTIONS ON SAFETY

●

Keys to Warning Symbols

●

Alert Statements

●

Explanation of signs

Indicates a potentially hazardous situation which, if not avoided, will

result in minor or moderate injury, or may result in serious injury or

death. Additionally there may be significant property damage.

WARNING

Thank you for selecting OMRON product. This sheet primarily describes

precautions required in installing and operating the product. Before operating

the product, read the sheet thoroughly to acquire sufficient knowledge of

the product. For your convenience, keep the sheet at your disposal.

Refer to the user’s manual for details.

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

Manufacturer:

Omron Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

TRACEABILITY INFORMATION:

Importer in EU:

Omron Europe B.V.

Wegalaan 67-69

2132 JD Hoofddorp,

The Netherlands

PRECAUTIONS FOR SAFE USE

Please observe the following precautions for safe use of the products.

(1)Installation Environment

・

Do not use the product in environments where it can be exposed to inflammable/explosive gas.

・

To secure the safety of operation and maintenance, do not install the product close to

high-voltage devices and power devices.

(2)Power Supply and Wiring

・

Be sure to use a dedicated amplifier unit (E9NC-TA

□□

). Connecting to other amplifier unit

may cause damage or fire.

・

When shortening cables, be sure to connect wires according to the specifications.

Misconnection may cause damage or fire.

・

High-Voltage lines and power lines must be wired separately from this product. Wiring them

together or placing them in the same duct may cause induction, resulting in malfunction or damage.

・

Always turn off the power of the unit before connecting or disconnecting cables.

・

To prevent cables to cut, fix it in a place where too much tension should not be applied to it.

Avoid pulling cables too strongly or bending them too much.

Repeated flexing: R50 or more

Permanent bend: R20 or more

・

Head and output cables must be placed separately from the power line.

(3)Installation

・

Use screws or tightening nut for mounting and be sure to tighten screws with a specified torque.

Specified torque: M3 screw:0.6N

・

m Tightening nut:1.0N

・

m

(4)Applicable

standards

・

EN61326-1

・

Electromagnetic environment : Industrial electromagnetic environment

(EN/IEC

61326-1

Table 2)

(5)Other Rules

・

Do not attempt to disassemble, deform by pressure, incinerate, repair, or modify this product.

・

When disposing of the product, treat as industrial waste.

・

If you notice an abnormal condition such as a strange odor, extreme heating of the unit, or

smoke, immediately stop using the product, turn off the power, and consult your dealer.

PRECAUTIONS FOR CORRECT USE

Please observe the following precautions to prevent failure to operate, malfunctions, or

undesirable effects on product performance.

(1)Do not install the product in locations subjected to the following conditions:

・

Surrounding air temperature outside the rating

・

Rapid temperature fluctuations (causing condensation)

・

Relative humidity outside the range of 35 to 85%

・

Presence of corrosive or flammable gases

・

Presence of dust, salt, or iron particles

・

Direct vibration or shock

・

Water, oil, or chemical fumes or spray, or mist atmospheres

・

Presence of intense magnetic, electric field or high frequency electric field (use the product in

a place distant from a noise source such as high power relay and high-voltage high-current

switch by 0.5 m or more)

(2)Warming up

・

The circuitry is not stable immediately after turning the power ON, and the values gradually

change until the Sensor Head is completely warmed up.

・

Before using the product, check that its functionality and capability are normal.

(3)Maintenance and inspection

・

Always turn off the power of the unit before connecting or disconnecting cables.

・

Do not use thinner, alcohol, benzene, acetone, or kerosene to clean the sensor.

・

If oil that becomes extremely viscous when it's dry, such as cutting oil, attaches to the rubber

boot, the operation may not work properly.

Wipe off with a waste cloth dampened with absolute alcohol.

・

The rubber boot may be significantly degraded by organic solvent or ozone in the air or

ultraviolet rays in the environment. In such cases, replace the rubber boot regularly (6 months to

a year).

・

Rubber boots are coated with grease. Please do not remove the grease when the rubber boot is

used, since sliding movement may be degraded if it is removed.

・

When it used after wiping off the oil, perform regular maintenance not to rust. Be sure to check

that there is no influence on the measurement due to the oil when it is used with the oil.

■

Do not use this product under water, rain or outdoors.

Push the operation lever at the operation slot with the slotted

screwdriver and pull out the wire to adjust the cable length.

The tip of the screwdriver must be 2 mm or less. The type of

screwdriver whose tip width becomes broaden toward its root

cannot be used.

■

Shortening the connection cable for use

■

Shortening the connection cable for use

(3) Push the slotted screwdriver all the way to the releasing slot

and pry the slotted screwdriver up and down lightly. When you

feel a click on the slotted screwdriver, pry it to the reverse

direction of the wire insertion direction. The operation lever will

recover with a click sound.

(4) Check that the operation lever recovers and the wire coating

enters into the wire insertion slot. The shield wire cover must

not be shorted circuited. (The wires are connected when you

pull the wire and feel a resistance.)

(1) According to "STRIP GAUGE" shown on the side of the

product, strip the coating of the shield for 20 mm or less, strip

the coating of the core wire for 7 to 8 mm, and twist the wire

for several times.

(2) Insert the wire all the way to the wire

insertion slot. Make sure that the wire coating

is located inside the wire insertion slot and

the tip of the conductor passes through the

connection part. Connect wires as follows.

Terminal No.1: Brown, No.2: Shield, No.3:

White, No.4: Red.

■

Procedure to connect the connector

Operation lever (White)

7 to 8 mm

Connecting part

Wire coating

Wire insertion port

Operation lever

(White)

Release port

66

70

(77.25)

(Ø12)

(30)

15

10 18

11.5Dia

Suitability for Use

s

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

Oct, 2014

D

OMRON Corporation

Industrial Automation Company

Contact: www.ia.omron.com

Tokyo, JAPAN

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

Regional Headquarters

8

(Using E9NC-TH5□)

18

(UsingE9NC-TH12□)