4

5

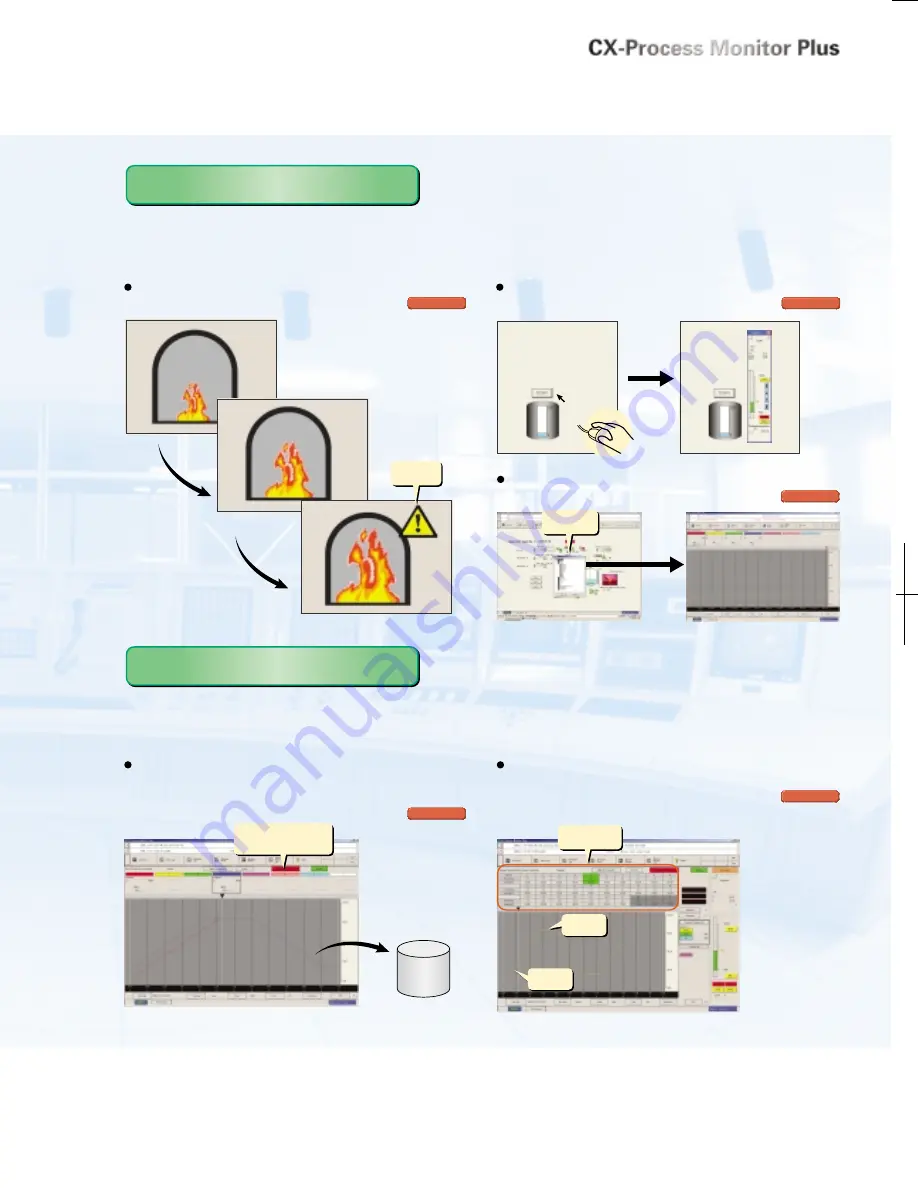

Various Screen Functions

Various Screen Functions

Control Screens

Up to eight tags can be allocated. By

allocating tags, it is possible to display

faceplates based on the function. The loop

status can be monitored and controlled in

the faceplate.

Trend Screens

Control Block values such as the SP and MV

can be displayed as a trend graph. There

are three kinds of trends: realtime trends,

historical trends, and batch trends. And up

to 8 trends can be displayed in one Trend

Screen. The collected data can be saved

automatically or manually in CSV format.

The defined trend points can be changed,

deleted, or added offline.

Tuning Screens

Tuning Screens display the parameters that

can be tuned in faceplates and trend graphs

displaying the PV, SP, or MV. Parameters

can be adjusted while monitoring operation

in the trend graph in 1-second intervals.

Other Screens

Other helpful screens are provided, such as

System Monitor Screens, Annunciator

Screens, and Operation Guide Message

Screens. System Monitor Screens can

display the status of the CPU and Loop

Controller as well as the error status of

Blocks. Annunciator Screens can display up

to 16 alarm displays per screen. Operation

Guide Message Screens can display

messages that were registered in advance

by the user.

Alarm Log Screens

The Alarm Log can be displayed in

historical order. Alarms resulting from

deviation alarms or bit status can also be

displayed in the Alarm Log, in addition to

the Control Block's HH, H, L, and LL alarms.

Operation Log Screens are also available to

sequentially display values manipulated

from Control Screens, Tuning Screens, or

Graphic Screens.

Version 2.0 or Higher

Version 2.0 or Higher

Version 2.0 or Higher

Function Upgrades

Function Upgrades

in CX-Process Monitor Plus

Version 2.0

in CX-Process Monitor Plus

Version 2.0

Function Upgrades

Function Upgrades

in CX-Process Monitor Plus

Version 2.0

in CX-Process Monitor Plus

Version 2.0

Images can be changed, displayed, hidden, or made to

flash based on the values of tags (data).

A Faceplate Button can be set up to display a faceplate

in a Graphic Screen.

A screen jump element can be set up to easily switch

screens.

Value: 20

Automatically saved.

Value: 50

Value: 80

CX-Process Monitor Plus Functions

Move to

selected

screen.

Screen selection

dialog box

SP

Segment Program

2 settings

PV

Click

Display/Hide

switch

A Wide Variety of Screens Is Available, and PLC-based Process

Control Systems Can Be Constructed Flexibly and Inexpensively.

With the Upgraded Graphic Functions, It Is Easy to Configure

the Monitoring Screens Needed for the Overall System.

With the Upgraded Trend/Segment Functions, It Is Easy to Read

Changing Analog Values.

The CX-Process Monitor Plus can be used to import tag data (CSV file format) of the function blocks in a Loop Controller,

and easily create screens such as Control Screens (on-site instrument images), Trend Screens, Graphic Screens, and

Annunciator Screens.

Graphic Screens

Dynamic symbols (elements that change with

the tag's value), such as valves, pumps, and

numerical values, can be allocated freely.

Lines, rectangles, and ellipses can also be

drawn, the color of those elements can be

changed, and the elements can be made to

flash. Static symbols or bitmap images

created in standard graphics software can be

read as images and displayed.

Version 2.0 or Higher

Version 2.0 or Higher

Use a specified tag (data) value to start or stop data

collection in a Batch Trend Screen. It is also possible to

automatically save past data, read that past data, and

superimpose it on the chart.

The PV trend can be displayed against the SP by setting

the segments in table format in the Segment Program 2

Screen.

Start data collection with a

screen operation or a data-

collection status trigger.