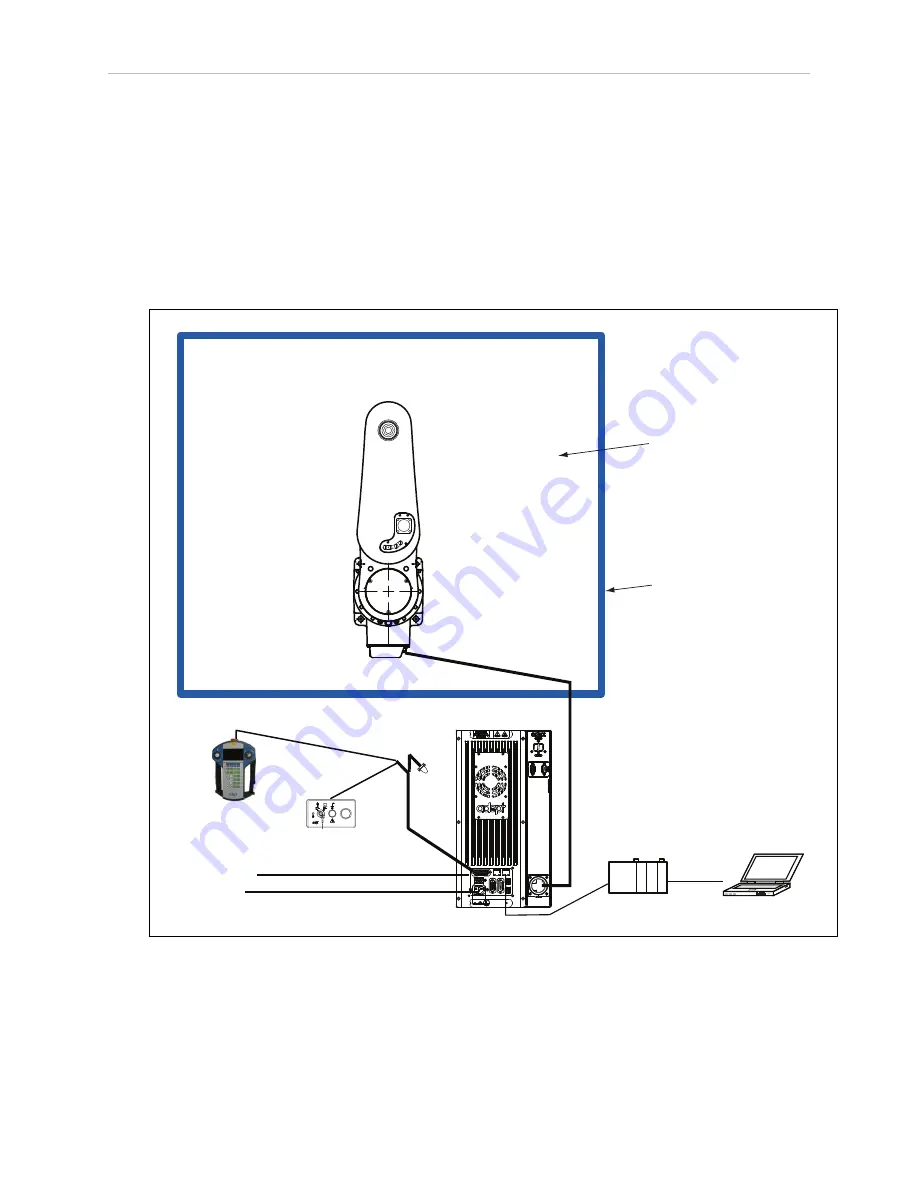

1.3 Workcell Layout

You must read the Robot Installation and Operation chapters in the

Cobra 350 Robot User's

Guide

for information on safe operation of your robot system, and the

Robot Safety Guide

.

Refer to Installing User-Supplied Safety Equipment in the System Installation chapter of the

Cobra 350 Robot User's Guide

, which provides details on connecting a user-designed E-Stop sys-

tem to the XUSR connector on the robot.

1.3 Workcell Layout

The following figure shows a simple workcell layout with a user-supplied safety barrier and

E-Stops provided by the Front Panel and optional T20 pendant.

DC

IN

24V

GND

AC

200 -

240V

Ø

1

XBEL

TIO

XIO

Servo

ENET

ENET

XSYSTEM

Front Panel

T20 Pendant -

Optional

PC running

PLC Programming

Software

Safety Barrier

Restricted Area

Inside Safety

Barrier

200-240 VAC

Cobra

ePLC350 Robot

24 VDC

XUSR

eMB-40R Amplifier

Programmable

Logic

Controller (PLC)

User-Supplied

Components

STOP

R

Figure 1-1. Typical Workcell Layout

Cobra ePLC350 Quick Setup Guide, 13590-000 Rev D

Page 4 of 14

Summary of Contents for Cobra 350 ePLC

Page 1: ...I592 E 01 Cobra 350 ePLC Robot Quick Setup Guide ...

Page 13: ......