4

To avoid crushing and related injuries:

• Never work on, under or around a load supported

only by hydraulic jack.

• Always use adequately rated jack stands.

• Chock each unlifted tire in both directions.

• Do not use this device to lift, level, lower, support

nor move a house, mobile home, travel trailer,

camper or any building structure.

• Be alert and sober when using this product.

Do not operate under the influence of drugs or

alcohol.

!

WARNING

X

!

WARNING

• Study, understand, and follow all instructions

before operating this device.

• Do not exceed rated capacity.

• Use only on hard, level surface.

• This is a lifting device only. Immediately after

lifting, support the load with appropriate means.

• Lift only on areas of the vehicle as specified by

the vehicle manufacturer.

• No alterations shall be made to this product.

• Only attachments and/or adapters supplied by

the manufacturer shall be used.

• Failure to heed these markings may result in

personal injury and/or property damage.

OPERATION

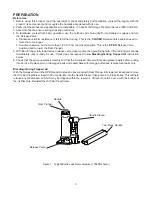

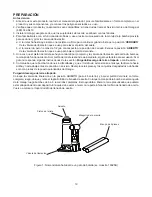

Raising the Ram Plunger

1. Assemble Pump Handle, align spring clips with corresponding slots.

2. Place vehicle in park, with emergency brake on and wheels securely chocked to prevent inadvertent vehicle

movement.

3. Locate and close Release Valve by turning Pump Handle clockwise until firm resistance is felt.

4. Verify lift point, center jack Saddle under lift point.

5. Insert Pump Handle into Handle Sleeve and pump to contact lift point. To lift, continue pumping until load reaches

desired height.

6. Transfer the lifted load to a pair of appropriately rated jack stands.

NOTICE:

Use Pump Handle provided by jack manufacturer. The handle provided with this jack will safely engage

the release valve and operate the Handle Sleeve. If handle is worn, operates abnormally, or will not positively engage

the release valve, STOP, discontinue use of the jack until a factory replacement handle can be acquired.

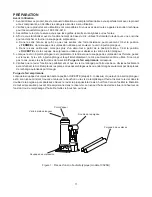

Lowering

WARNING:

Clear all tools and personnel before lowering load. Open release valve slowly. The further handle is

turned counter-clockwise, the faster the load will descend. Maintain control of the load at all times.

1. Raise load high enough to clear the jack stands, then carefully remove jack stands.

2. Slowly turn the Pump Handle counter-clockwise, but no more than 1/2 turn.

If the load fails to lower

:

a. Use another jack to raise the vehicle high enough to reinstall jack stands.

b. Remove the affected jack and then the stands.

c. Use the functioning jack to lower the vehicle.

3. After removing jack from under the load, push Ram Plunger and Handle Sleeve down to reduce exposure to rust

and contamination.

!

Summary of Contents for 10025B

Page 8: ...SFA Companies 10939 N Pomona Ave Kansas City MO 64153 888 332 6419 sales omegalift com 8...

Page 16: ...SFA Companies 10939 N Pomona Ave Kansas City MO 64153 888 332 6419 sales omegalift com 16...

Page 24: ...SFA Companies 10939 N Pomona Ave Kansas City MO 64153 888 332 6419 sales omegalift com 24...