CDi-16B - Installation and operating manual

www.omega-air.si

11

Maintenance

Service:

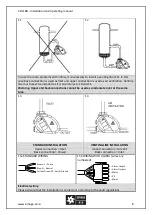

It is recommended to clean the device at least once a year. Sealing and valve elements are

subject to wear, which depends on various operating parameters such as pressure,

temperature, dirt content, etc.

For trouble free operation it is strongly recommended to change wearing parts every:

8000 operating hours of compressor

3 years in use regardless compressor operating hours

All parts that are subject to wear are packed in SERVIS KIT CDi 16-B.

Attention

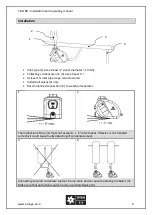

Before beginning maintenance work take the drain out of operation, switch off the power

supply and depressurize the unit.

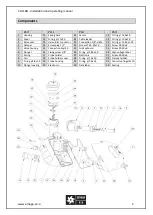

Service kits

Based on type of CDi-16B drain following servis kits can be used:

SERVIS KIT CDI 16-B 230V

SERVIS KIT CDI 16-B 115V

Servis procedure

Read complete installation and operating manual before beginning any maintenance or

service work.

Depressurize the unit, take the drain out of operation and switch off the power supply

Unscrew four screws (24) from drain housing and remove cover (2).

Remove worn components from the device and replace them with components you will

fint in SERVICE KIT.

Put che cover (2) back on and tighten it with four screws (24).

Before putting the device back to operation check for leackage and test proper

operating by pressing TEST button.