AOK 20SS - Installation and operating manual

7

Maintenance

Warning

Before maintenance depressurize the device and keep to the

safety rules when working with pressure equipment.

Weekly:

Rotate the "Test" button and manually drain the accumulated condensate until air

begins to blow from the drain. If a significant amount of water (more than 0.5 liters)

exits the valve then the drain must be thoroughly cleaned.

Yearly:

Clean interior of the reservoir regularly. Intervals of cleaning depend on

contamination of condensate. Replace the sealings if necessary. Make a visual check

of the drain and make sure there is no visual damage or leakage.

Service:

It is recommended to clean the reservoir at least once a year. Sealing elements are subject to wear,

which depends on various operating parameters such as pressure, temperature, dirt content, etc. It is

also recommended to change seals.

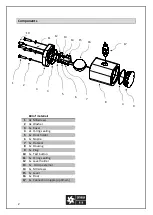

Spare parts:

Replacement seals are available on demand. Please contact your distributor or manufacturer.

Warranty exclusion

The guarantee shall be void if:

The installation and operating manual was not followed with respect to installation,

initial commissioning and maintenance.

The unit was not operated properly and appropriately.

The unit was operated when it was clearly defective.

Non-original spare parts or replacement parts were used.

The unit was not operated within the permissible technical parameters.

Unauthorized constructional changes were made to the unit or if the unit has been

opened/disassembled by an unauthorized person.