27

APPENDIX A - CONTROL MODULE

A.1 Installation Environment Considerations

WARNING

If you do not follow these instructions

exactly, a fire or explosion may result

causing property damage, personal injury

or loss of life.

• Do not use this appliance if any part has

been under water.

Immediately call a qualified

service technician to inspect appliance and to

replace any part of control system and any gas

control which has been under water.

• Do not allow water to drip on controls. Prevent

condensation by allowing air circulation around

module and gas control.

• Do not use corrosive chemicals around or on

module or gas control.

!

• Controls can be damaged by excessively high

temperatures. Verify adequate air circulation around

control is maintained when installing boiler.

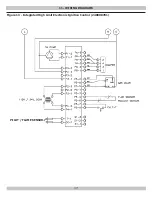

A.2 Electrical Connections

Connect Module Connectors Figure 14, Page 18

• L1& L2 leads inside J-box using wire nuts. Secure J-

box cover.

• Circulator harness to circulator. Harness comes

plugged into module with Molex

®

plug.

• Thermostat connection to yellow wires marked TT

using wire nuts.

• Ensure remaining Molex

®

plug connectors have not

worked loose during transit.

• Check sensing bulb is fully inserted in well and is not

loose.

• Refer to enclosed addendum for wiring instructions

when using indirect hot water heater.

A.3 Adjusting Settings

To discourage unauthorized changing of settings, procedure

to enter adjustment mode is required.

To enter adjustment mode, press UP, DOWN, and I buttons

simultaneously for three seconds. Press and release I

button until parameter requiring adjustment is displayed.

See Figure 12, page 16.

о

“SP_” Setpoint (180 °F default setting; adjustable

between 130 and 220 °F) Note: on some models

this is “HL” High Limit.

о

“Df_” Setpoint Differential (15 °F default setting;

adjustable between 10 and 30 °F)

о

“°F_” Degrees Fahrenheit

Press UP or DOWN button until parameter has reached

desired value. After 60 seconds without any button inputs,

control automatically returns to READ mode.

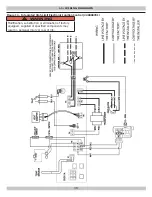

A.4 Display

In RUN mode, status items and parameters are viewable.

Example

, to display setpoint, control flashs “sp” (setpoint)

followed by temperature (i.e., 135), followed by °F or °C.

To read settings, press and release I key to find parameter

of interest.

Example,

press and release I until setpoint (sp) is

displayed, followed by three-digit number, i.e., 190,

followed by °F or °C. Press I button again will display (S1T)

Sensor 1 Temperature followed by three-digit number and

corresponding degree designator.

See Display Readout.

Figure 18 - Display Readout