2H0/2HZ

1-5-26

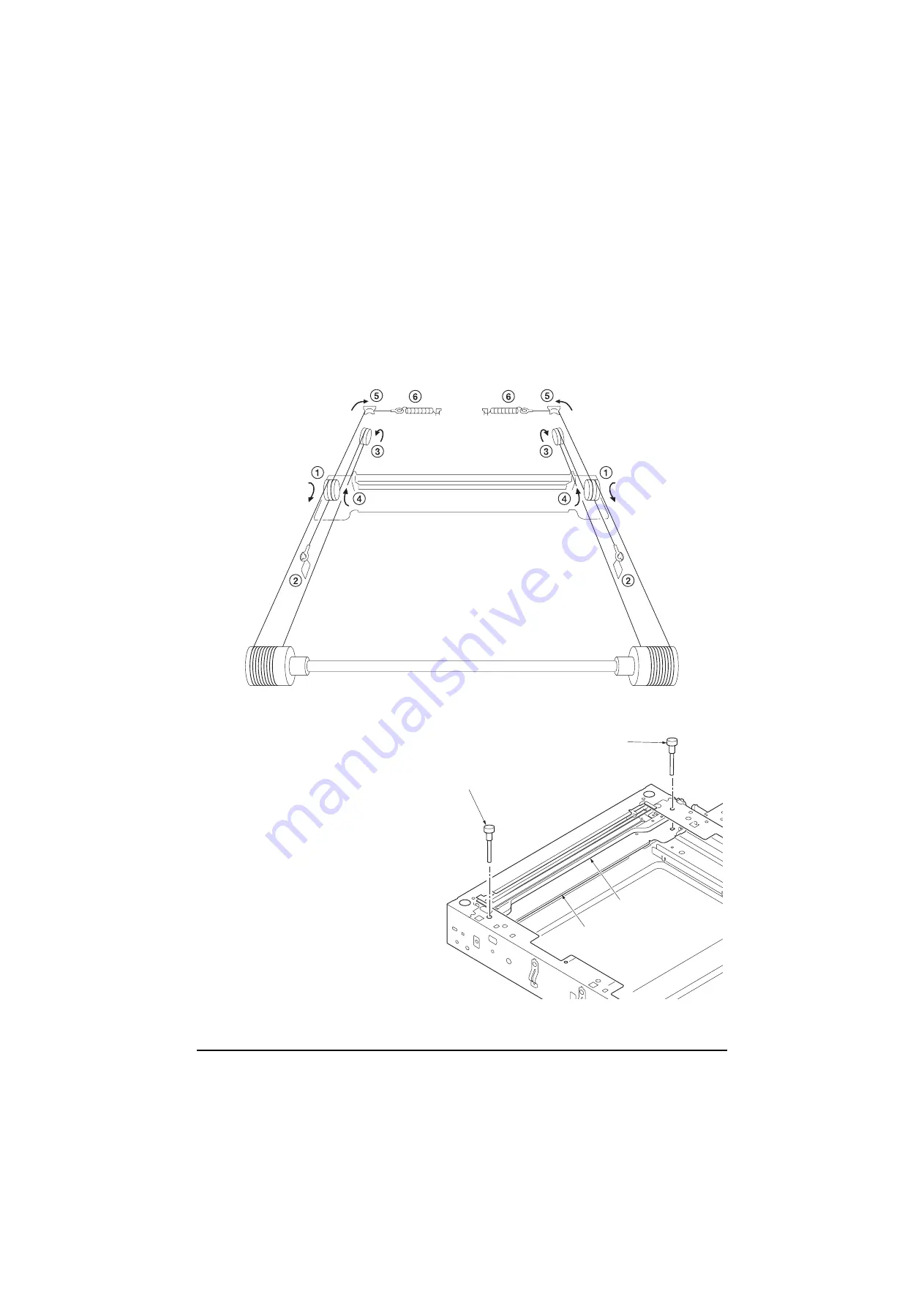

8. Loop the outer ends of the scanner wires around the outer grooves in the pulleys on the mirror 2 frame,

winding from below to above. .......................................................................................................................... (1)

9. Hook the round terminals onto the catches inside the scanner unit. ............................................................... (2)

10. Loop the inner ends of the scanner wires around the grooves in the pulleys at the left of the scanner unit,

winding from below to above. .......................................................................................................................... (3)

11. Loop the scanner wires around the inner grooves in the pulleys on the mirror 2 frame, winding from

above to below................................................................................................................................................. (4)

12. Wind the scanner wires around the grooves in the scanner wire guides at the left of the scanner unit. ......... (5)

13. Hook the round terminals onto the scanner wire springs................................................................................. (6)

Figure 1-5-47

14. Remove the two scanner wire stoppers and

frame securing tools.

15. Focusing on the locating ball of the wire

drum, move aside the wires to inside.

16. Move the mirror 2 frame from side to side to

correctly locate the wires in position.

17. Refit the mirror 1 frame.

18. Move the mirror 1 and 2 frames to the

machine left, and insert the two frame secur-

ing tools into the positioning holes at the

front and rear of the scanner unit to secure

the frames in position.

19. Hold the wires and fix each front and rear

wire holder plate to mirror 1 frame with the

screw.

20. Remove the two frame securing tools.

21. Refit all the removed parts.

Figure 1-5-48

Frame securing tool

Frame securing tool

Mirror 2 frame

Mirror 1 frame

Service Manual

Y108620-5

Summary of Contents for d-Copia 2500MF

Page 1: ...d Copia 2500MF d Copia 3000MF Digital Copier SERVICE MANUAL Code Y108620 5...

Page 4: ...This page is intentionally left blank...

Page 10: ...This page is intentionally left blank...

Page 14: ...2H0 2HZ This page is intentionally left blank...

Page 20: ...2H0 2HZ 1 1 6 This page is intentionally left blank Service Manual Y108620 5...

Page 258: ...2H0 2HZ 2 1 20 This page is intentionally left blank Service Manual Y108620 5...

Page 296: ...UPDATING STATUS DATE UPDATED PAGES PAGES CODE 10 2007 1ST EDITION 296 Y108620 5...