10014 Planer

OLIVERMACHINERY.NET

31

|

Page

Operation

For safety and best results, please take the following steps for operating this machine.

Step 1: Preparation

Only Use Natural, Good Quality Wood

Only plane natural wood materials that is in good quality. Cracked stock, board with loose knots,

plywood and other engineered wood products can break apart and cause severe kickbacks, which can

lead to severe injuries and machine damages.

Do not plane treated lumber or anything that contains harmful chemicals, as this will spread wood dusts

that contain such harmful chemicals. NEVER plane boards that are shorter than 7”as mentioned in the

specifications.

Inspect the Workpiece

Carefully inspect the workpiece for foreign objects. Nails, staples, rock chips and other objects

embedded on the wood surface will damage the planer. To avoid chipping/dulling the cutter inserts, it is

advised to clean a workpiece with a stiff brush to remove all dirt and foreign objects before planing,

especially for rough sawn or reclaimed lumber. Use metal detector to scan for metal as needed.

Check Moisture Content

Check moisture content of the workpiece before operation. “Green wood” with moisture content over

20% will not cut properly and may jam the machine. Excessive moisture content will also cause planer’s

unpainted surface to rust. Besides, as the workpieces dries, the planed surface will become fuzzy, and

the workpiece may wrap. It is recommended to allow the workpiece to dry and stabilize before it is

processed.

Wrapped Stock

Workpiece should have a flat bottom to be processed by a planer. It is acceptable to process a slightly

cupped board with the cupped side facing down and begin with light cuts. Boards with moderate

cupping, bowing or twisting should have one side face-jointed before being processed by a planer.

Avoid using boards with severe wrapping, as they can be unstable and might cause severe kickbacks

during operation.

Glue-Ups

Glue left on the workpiece surface can dull the cutters and reduce cut quality. Scrape off all glue from

the workpiece before operation.

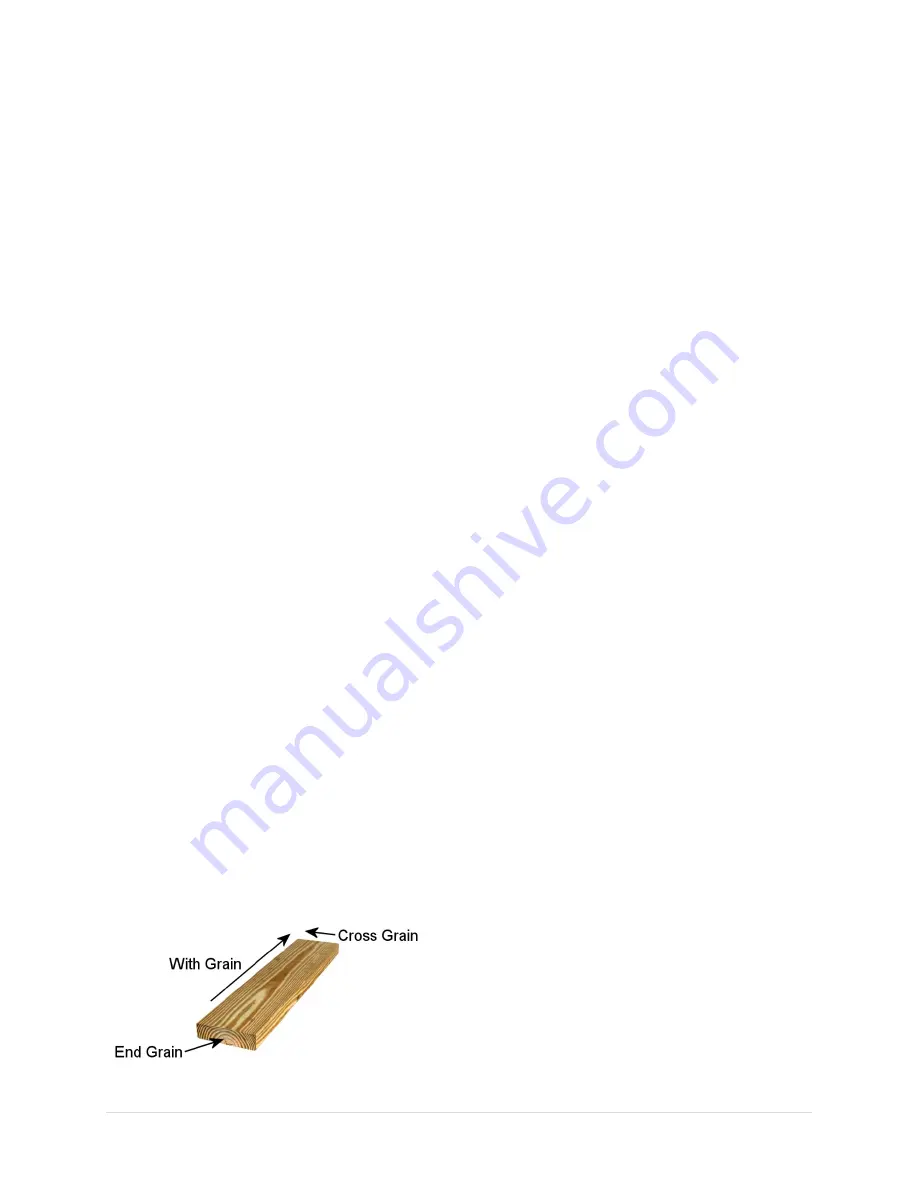

Wood Grain Direction

This planer is designed to plane WITH the grain direction of the wood. Do not plane cross-grain or end-

grain. Severe kickback and chipping may occur.

Summary of Contents for 10014

Page 2: ......

Page 10: ...10 Page Oliver Machinery 10014 Planer Identification...

Page 11: ...10014 Planer OLIVERMACHINERY NET 11 Page...

Page 12: ...12 Page Oliver Machinery 10014 Planer...

Page 38: ...38 Page Oliver Machinery 10014 Planer Figure 1 Figure 2 Figure 3 Figure 4 Figure 5 Figure 6...

Page 44: ...44 Page Oliver Machinery 10014 Planer between the cutterhead and the feed rollers...

Page 51: ...10014 Planer OLIVERMACHINERY NET 51 Page WiringDiagram...

Page 52: ...52 Page Oliver Machinery 10014 Planer PartsList Table Assembly...

Page 53: ...10014 Planer OLIVERMACHINERY NET 53 Page Cabinet Assembly...

Page 54: ...54 Page Oliver Machinery 10014 Planer Motor Mount Assembly...

Page 55: ...10014 Planer OLIVERMACHINERY NET 55 Page Headstock Assembly...

Page 56: ...56 Page Oliver Machinery 10014 Planer Gearbox Assembly and Dust Port Assembly...

Page 62: ...62 Page Oliver Machinery 10014 Planer MaintenanceRecord Date Task Operator...

Page 63: ...10014 Planer OLIVERMACHINERY NET 63 Page Notes...