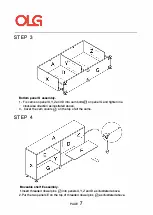

STEP 3

Bottom panel G assembly.

1 � Fix cams on panel X,Y,Z and D into cam bolts@) on panel G and tighten in a

clockwise direction as illustrated above.

3, Cover the cam covers

@

on the top of all the cams.

STEP 4

Moveable shelf E assembly.

1.lnsert threaded dowel pins

(ey

into panels X,Y,Z and Das illustrated above.

2.Put the two panels E on the top of threaded dowel pins

@

as illustrated above.

PAGE

7

Summary of Contents for AXC18

Page 1: ...TOOLS REQUIRED Powered screwdriver Installation Guide myolgoffice com Bookcase...

Page 2: ...BOOKCASE Installation Guide PARTS PAG...

Page 5: ...ASSEMBLY INSTRUCTION AXIS Cupboard 1800H ITEM No AXC18 PAGE 1...

Page 6: ...Incorrect Correct r The turning direction of attaching The arrow direction front V2 V1 PAGE 2...

Page 14: ...ASSEMBLY INSTRUCTION AXIS Caddy Bookcase 993W ITEM No AXCMB PAGE 1...

Page 15: ...Incorrect Correct The turning direction of attaching The arrow direction front PAGE 2...

Page 21: ...ASSEMBLY INSTRUCTION AXIS System Tambour Insert Studio ITEM No AXCTI PAGE 1...

Page 22: ...11ie turning direction of attaching X1 C 11ie mTOlr directiCJll i ront Roller door PAGE 2...

Page 27: ...ASSEMBLY INSTRUCTION AXIS Credenza 1800W ITEM No AXCZ18 PAGE 1...

Page 28: ...Incorrect Correct The turning direction of attaching The arrow direction front V4 V3 V1 PAGE 2...

Page 36: ...ASSEMBLY INSTRUCTION Axis Locker Single ITEM No AXLOC1 PAGE 1...

Page 44: ...ASSEMBLY INSTRUCTION Axis Locker Single ITEM No AXLOC2 PAGE 1...

Page 53: ...ASSEMBLY INSTRUCTION AXIS Planter for Tambour Cabinet 750W ITEM No AXPBOX200 PAGE 1...

Page 54: ...The turning direction of attaching Incorrect Correct The arrow direction front PAGE 2...

Page 58: ...STEP 4 6 PCS Transparant plastic sticker I PAGE 6...

Page 60: ...ASSEMBLY INSTRUCTION AXIS Tambour Cabinet 1250H ITEM No AXT12 PAGE 1...

Page 61: ...Incorrect Correct The turning direction of attaching The arrow direction front PAGE 2...

Page 68: ...ASSEMBLY INSTRUCTION AXIS Tambour Cabinet 900H ITEM No AXT9 PAGE 1...

Page 69: ...Incorrect Correct The turning direction of attaching The arrow direction front PAGE 2...

Page 76: ...ASSEMBLY INSTRUCTION AXIS Tambour Mobile ITEM No AXTM PAGE 1...

Page 77: ...Incorrect Correct The turning direction of attaching The arrow direction front PAGE 2...

Page 79: ...STEP 1 Preparation for Tambour Mobile A 1 Assemble castor with screws on bottom panel G PAGE 4...