Construction Manual

www.oldschoolmodels.com

Page 5

Step 15 - Wing Assembly (top spar)

Locate another of the 3/16” x

3/8” basswood strips to use as

the upper spar. Measure, cut

and glue into position as shown.

Make sure the spar is pushed

all the way into each of the rib’s

slots, and is glued to each of

the ribs and sheer webs.

Step 16 - Wing Assembly (TS1 & TS2)

Locate one of the TS1’s from BP6 and a

TS2 from BP5. These are glued together

as shown here.

Step 17 - Wing Assembly (TS3)

Locate one of the TS3’s from BP6.

This is glued to the end of the TS1/

TS2 assembly from the previous

step, as shown here.

Step 18 - Wing Assembly (top sheeting)

Now the top sheeting assembly you’ve just glued together is

attached to the wing.

It’s best to do this a little at a time, starting with the leading edge.

It’s also a good idea to have a long straight-edge (such as a metal

yardstick) to aid in holding the sheeting.

Run a bead of glue along the front

edge of the wing sheeting. Then place

the sheeting in position, making sure it

aligns with R1 and it is pressed against

the entirety of the leading edge. Pressing

that yardstick on top of the wood makes it

easier to hold long lengths of wood in place

with just two hands.

After the glue has cured, run beads of glue

along the tops of each rib, from the leading

edge, back to the upper spar. Roll the

leading edge sheeting onto this area and

press down, again with the yardstick.

Once cured, then glue the last section of the

sheeting to R1 and R2.

Step 19 - Wing Assembly (trailing edge sheeting)

Locate two more lengths of the laser-cut 1” strips

that are cut into several of the 1/16” sheets (BP5,

BP6, and BP7). These two pieces will need to be

joined together to make a long enough strip to form

the upper trailing edge. Measure and trim to length,

then pin and glue into position. Again, the joint

should be on an angle, not a 90° butt-joint.

Step 20 - Wing Assembly (WH1)

Locate WH1 from LP1. Also cut a 3/4”

piece from the leftover 3/16” x 3/8”

basswood used in the spars. Glue this

as shown here, centered on WH1 and

up against the hole. This will act as a

support in the next step.

Step 21 - Wing Assembly (WH1)

Glue WH1 into the gap between the leading

and trailing edge sheeting. The hole will be

positioned towards R1.

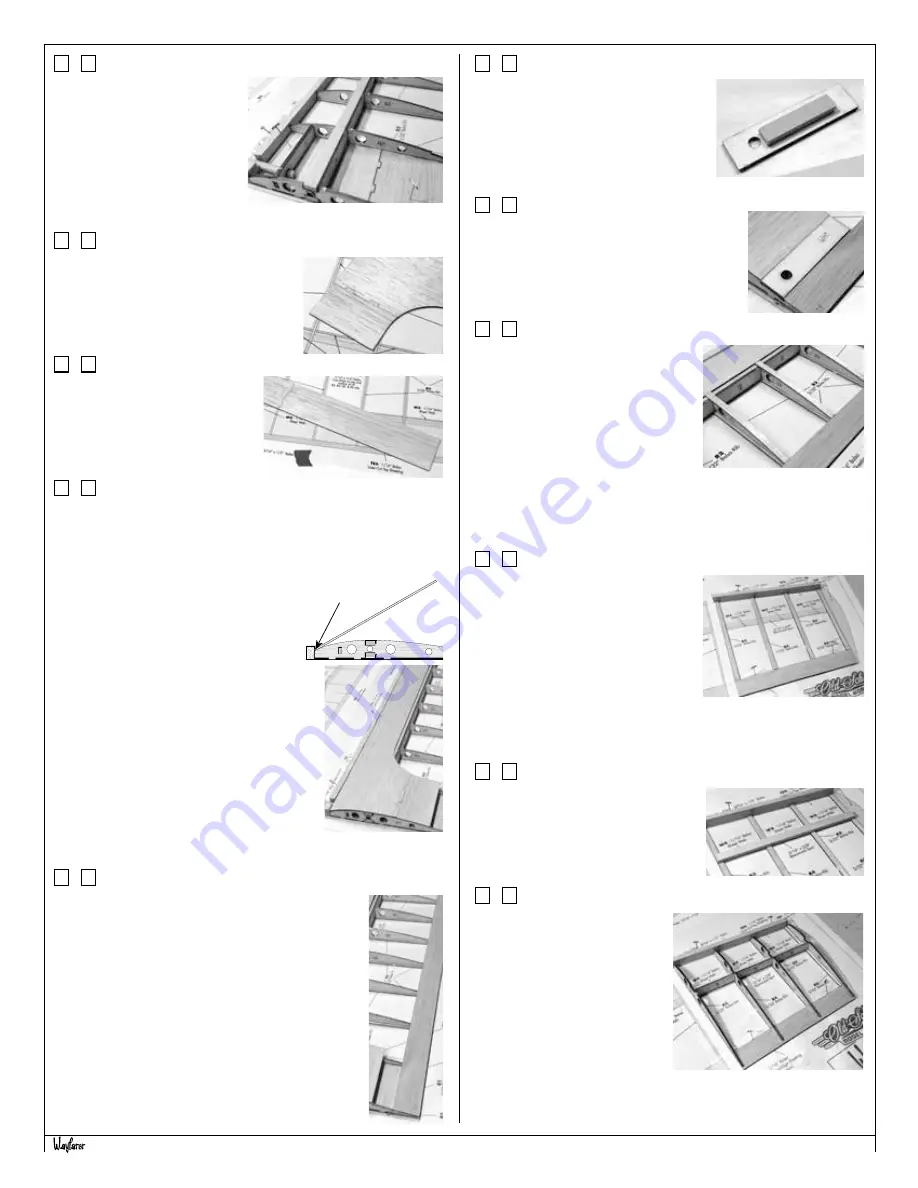

Step 22 - Wing Assembly (cap strips)

Locate a couple lengths of the laser-

cut 1/4” cap strips that are cut into

several of the 1/16” sheets (BP5, BP6,

and BP7). These are used to make

the upper cap strips. These strips run

from the trailing edge, to the rear of

the leading edge sheeting. Measure,

cut, pin and glue these into position

as shown.

Note that the cap strip on top of R3 should be positioned so it is

flush with outer edge of the rib, not overlapping it.

Step 23 - Wing Assembly (outer wing)

The outer panels are made the same

way as the inner wing you just built -

just smaller.

Locate a length of the laser-cut 1”

strip for the trailing edge and the

laser-cut 1/4” cap strips that are cut

into several of the 1/16” sheets.

Also cut a portion of the leading edge

5/16” x 1/2” strip. Measure, cut, pin and glue these into position

as shown here.

Step 24 - Wing Assembly (outer wing)

Cut a piece of the leftover 3/16” x

3/8” basswood strips to use as the

lower spar. Measure, cut and glue into

position as shown.

Step 25 - Wing Assembly (outer ribs)

Locate R6 from BP2, also one

W6 from BP8. Note that W6

tapers from one end to the

other. Fit the shorter end into R6

and glue at a 90° angle, making

sure it’s on the correct side.

When cured, glue this in

position. Now do the same with

R5 and R4.

R3 will be glued in place, but be

sure to use the 3° angle tool that you used previously.

Glue here

first